H-type broiler chicken cage with left and right waterline connection and fixing mechanism

A fixed mechanism and waterline technology, applied in the field of aquaculture equipment, can solve problems such as inconsistency in lifting heights, and achieve the effects of reducing interference, facilitating adjustment and maintenance, and reducing differences and individual growth differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

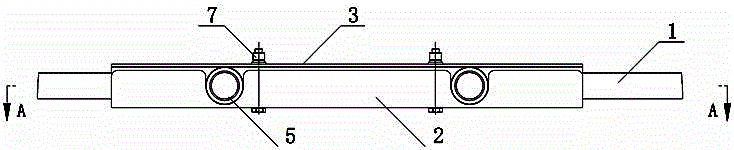

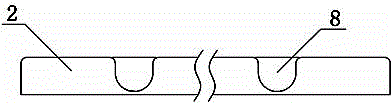

[0022] Such as figure 1 and figure 2 As shown, the H-type broiler cage uses the left and right water lines to connect the fixing mechanism, which includes the water line inlet pipe 1, the fixing plate A2, the fixing plate B3, the water line outlet pipeline 5 and the connecting bolt 7. The water line inlet The cross section of the water pipe 1 is a square structure, such as Figure 7 As shown, the cross section of the fixed plate A2 and the fixed plate B3 is a U-shaped structure, and the fixed plate A2 and the fixed plate B3 are buckled into one body, as shown in Figure 4 As shown, the middle part of the fixed plate A2 is provided with a through hole A9, such as Figure 5 and Figure 6 As shown, the middle part of the fixed plate B3 is provided with a through hole B10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com