Crushing and recycling device for building waste materials

A technology of recycling device and waste material, applied in the field of construction waste material crushing and recycling device, can solve the problems of low efficiency, slow crushing speed, poor recovery effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

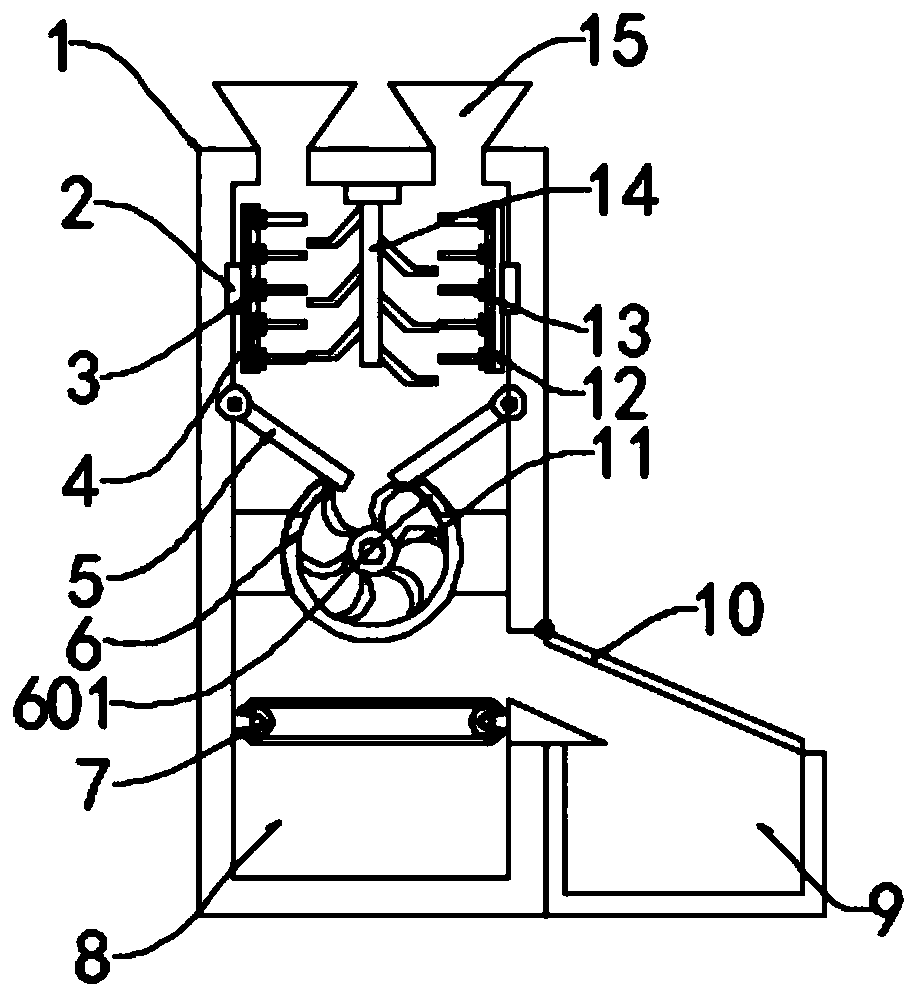

[0020] see Figures 1 to 3 :

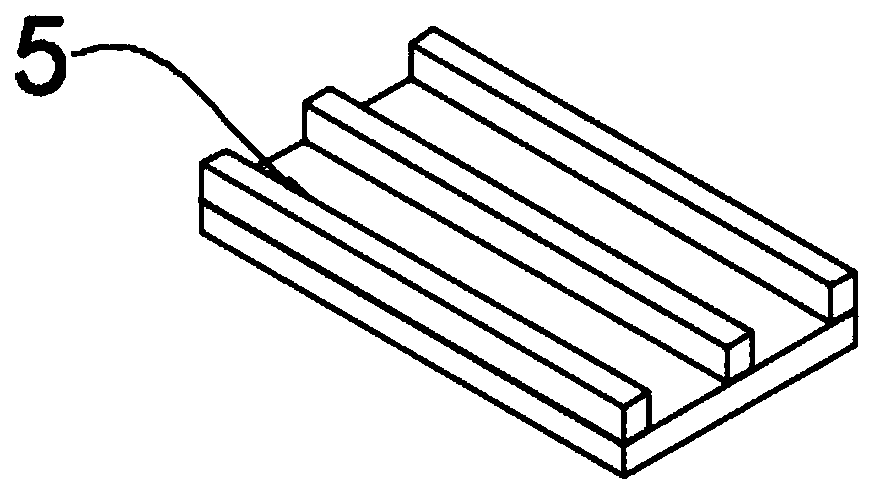

[0021] This embodiment provides a further preferred solution for a crushing and recycling device for construction waste materials, which includes a device main body 1 and a recovery box 9. The top and bottom sides of the device main body 1 are fixedly connected with feeding ports 15, and the upper part of the device main body 1 is fixedly connected with a stirring rod 14. , both sides above the main body 1 of the device are fixedly embedded with a turntable 2, and the outside of the turntable 2 is fixedly connected with a rotating rod 3, and one side of the rotating rod 3 is fixedly embedded with a guide rail 5, and the inside of the guide rail 4 is movably connected with a mounting plate 12, and the outside of the mounting plate 12 The fixed connection is connected with a cutter 13, the left and right sides below the rotating rod 3 are movable with a guide plate 5, the bottom of the guide plate 5 is fixedly connected with a crushing cylinder 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com