Anti-blocking type conversion inlet gas-liquid separator

A gas-liquid separator and anti-clogging technology, applied in the direction of using liquid separation agent, filtration separation, separation method, etc., can solve the problems of scaling and clogging of imported low-pressure waste boiler heat exchange tubes, and achieve the goal of avoiding scaling and clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

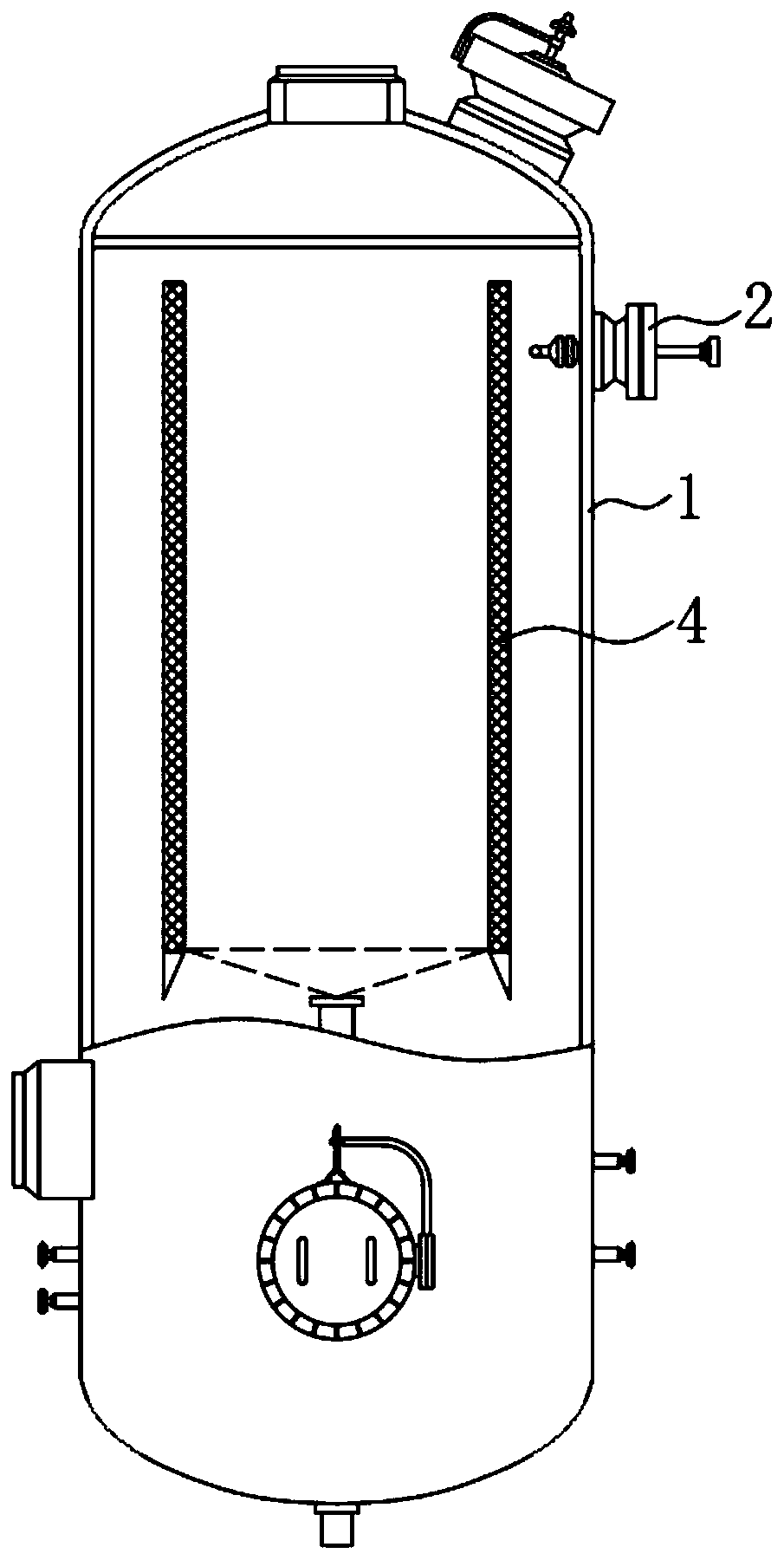

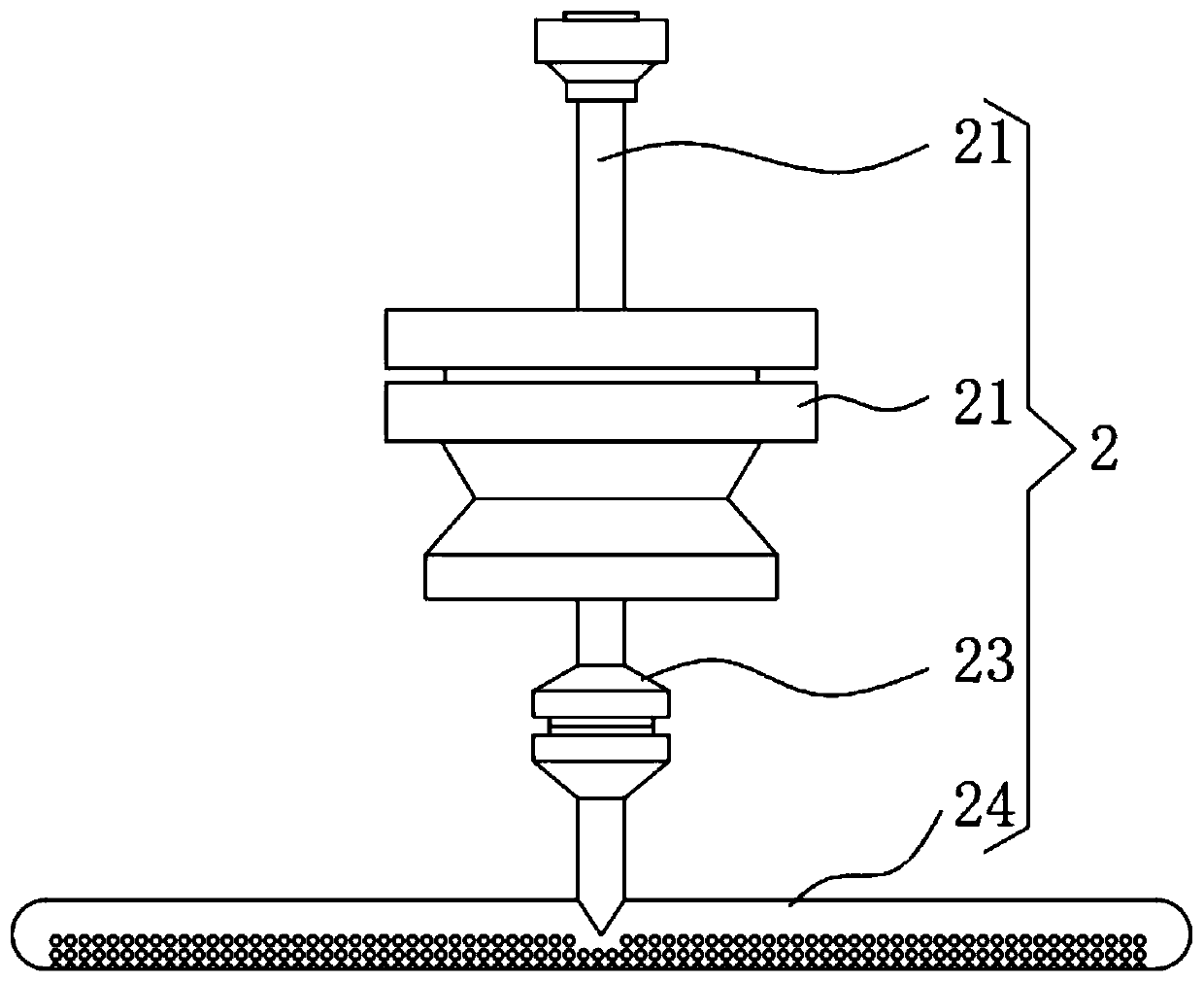

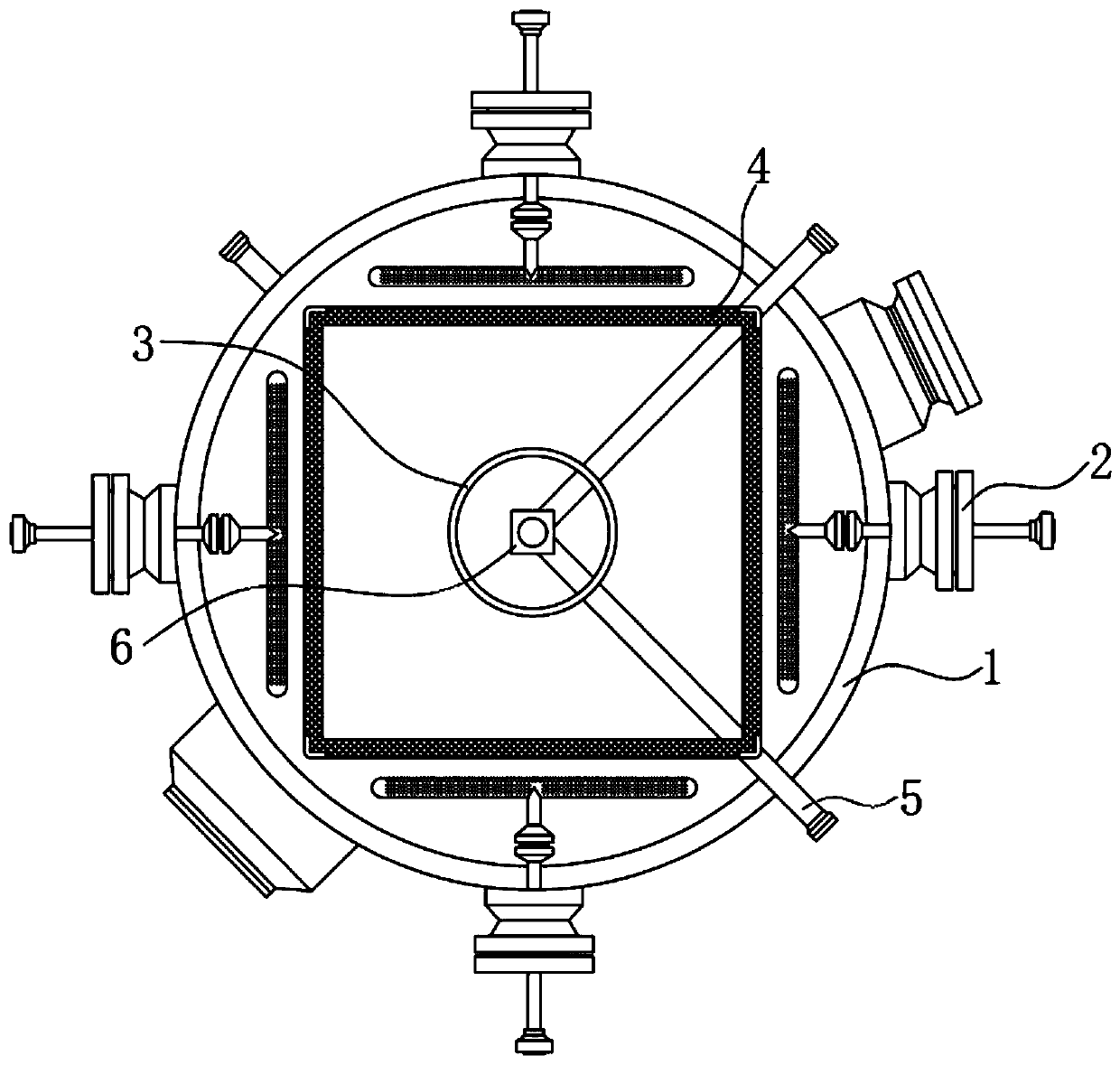

[0037] Please refer to figure 1 , figure 2 and image 3 ,in, figure 1 A schematic structural view of the first embodiment of the anti-clogging type conversion inlet gas-liquid separator provided by the present invention; figure 2 for figure 1 The schematic diagram of the structure inside the tank shown; image 3 for figure 1 Schematic diagram of the structure of the spraying device shown. Anti-clogging variable inlet gas-liquid separator, including:

[0038] Tank 1;

[0039] The spraying device 2, the spraying device 2 is arranged on the tank body 1, the spraying device 2 includes a fixing part 21 and a water conduit 22, and the fixing part 21 is welded on the outer surface of the tank body 1 One end of the water guide pipe 22 runs through the outside side of the tank body 1 and extends to the inside of the tank body 1, and the end of the wat...

no. 2 example

[0049] Please refer to Figure 4-5 ,in, Figure 4 A schematic structural view of the second embodiment of the anti-clogging type conversion inlet gas-liquid separator provided by the present invention; Figure 5 for Figure 4 The enlarged schematic diagram of part A is shown. Based on the anti-clogging type conversion inlet gas-liquid separator provided in the first embodiment of the present invention, the second embodiment of the present invention provides another anti-clogging type conversion inlet gas-liquid separator, wherein the second embodiment does not It hinders the independent implementation of the technical solution of the first embodiment.

[0050] Specifically, the present invention provides another anti-clogging type conversion inlet gas-liquid separator, which is different in that:

[0051] The inside of the fixing part 21 is provided with a rectangular groove 7, the inside of the rectangular groove 7 is provided with a filter device 8, the filter device 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com