Shoe sole and production process thereof

A production process and outer layer technology, applied to shoe soles, footwear, clothing, etc., can solve the problems of short service life of shoe soles, production pollution, high production costs, etc., and achieve the goal of improving service life, reducing production costs and prolonging service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

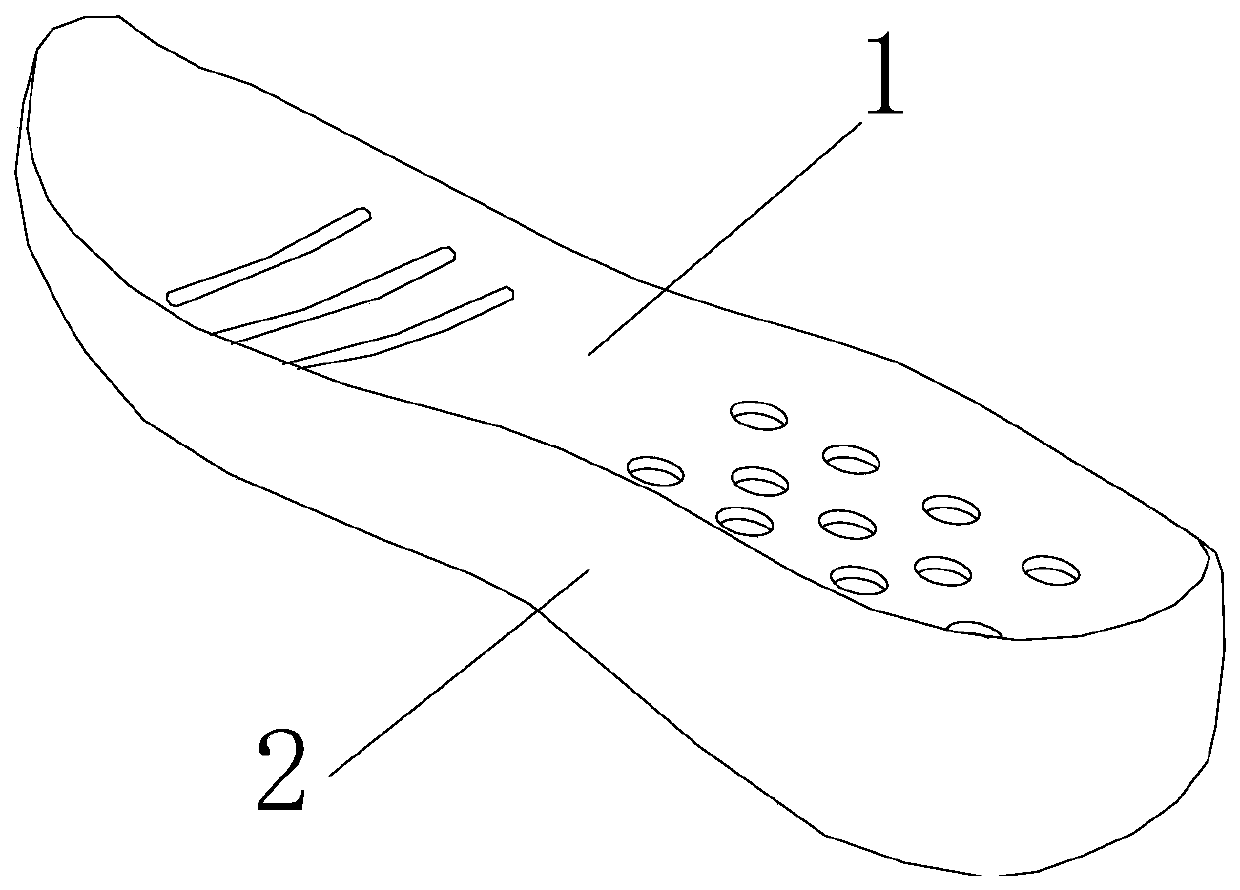

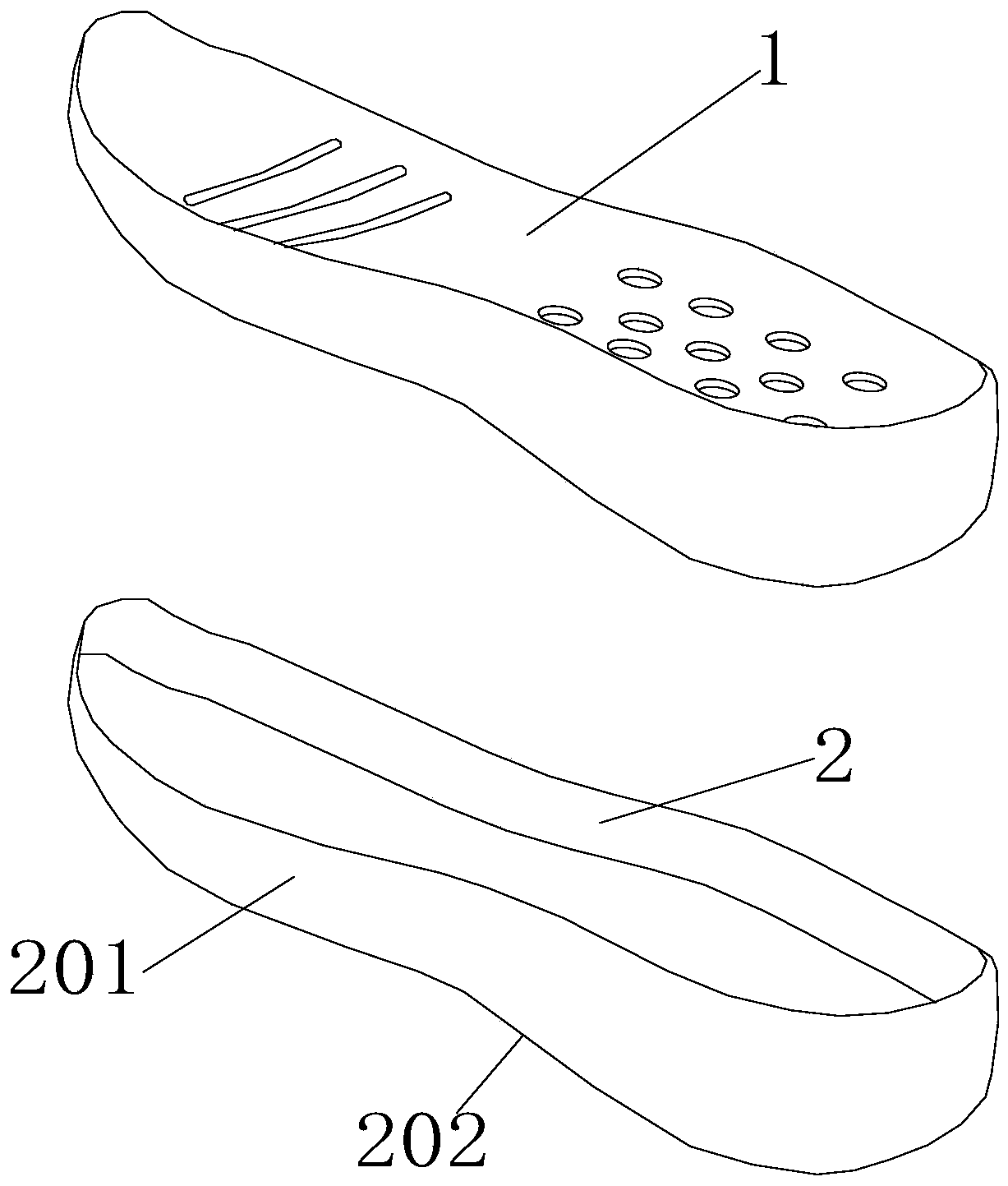

[0034] Example 1, see Figure 1 to Figure 2 , the first embodiment of the present invention provides a shoe sole, including a shoe outer layer 2 and a shock-absorbing layer 1, the material composition of the shock-absorbing layer 1 is the same or partly the same as the material composition of the shoe outer layer 2, and the shock-absorbing layer The shock layer 1 and the shoe outer layer 2 are composited by hot pressing; the shoe outer layer 2 is formed by hot pressing of the same sheet, which includes the bottom outer layer 202 on the bottom of the shoe and the side layer 201 on the side of the shoe , the bottom and sides of the shock-absorbing layer 1 are respectively wrapped in the bottom outer layer 202 and the side layer 201 of the shoe outer layer 2; The parts are the same or part of the same is compatible, and the two are compounded and connected to each other under the action of mold hot pressing to form a whole, replacing the traditional glue sticking.

[0035] In th...

Embodiment 2

[0040] Present embodiment 2 provides a kind of production technology of sole, comprises following manufacturing steps:

[0041] (1) 50 parts of EVA, 30 parts of rubber and 30 parts of elastomer are obtained by injection molding according to parts by weight, and the foamed material of EVA is used as the shock-absorbing sheet;

[0042] (1) Put the wear-resistant anti-slip sheet into the forming die groove so that it is attached to the bottom and side walls of the forming die groove;

[0043] (2) Putting a shock absorbing sheet on the above-mentioned wear-resistant anti-slip sheet, so that the described shock-absorbing sheet is directly above the wear-resistant anti-slip sheet;

[0044] (3) Set the hot-pressing temperature to 118°C, the hot-pressing pressure to 430KPa, and the hot-pressing time to 65s, close the molds, perform in-mould hot-pressing molding, and make the wear-resistant anti-slip sheet fit the shock-absorbing sheet through hot-pressing Wrapping from the bottom of th...

Embodiment 3

[0048] Present embodiment 3 provides the production technology of another kind of sole, comprises following manufacturing steps:

[0049] (1) 55 parts of EVA, 17 parts of rubber and 17 parts of elastomer are obtained by hot pressing according to the number of parts to obtain the wear-resistant anti-skid sheet, and the foamed material of EVA is used as the shock-absorbing sheet;

[0050] (1) Put the wear-resistant anti-slip sheet into the forming die groove so that it is attached to the bottom and side walls of the forming die groove;

[0051] (2) Putting a shock absorbing sheet on the above-mentioned wear-resistant anti-slip sheet, so that the described shock-absorbing sheet is directly above the wear-resistant anti-slip sheet;

[0052] (3) Set the hot-pressing temperature to 115°C, the hot-pressing pressure to 450KPa, and the hot-pressing time to 68s, close the molds, perform in-mould hot-pressing molding, and make the wear-resistant anti-slip sheet fit the shock-absorbing sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com