Preparation method and application of chlorine dioxide fruit and vegetable fresh-keeping slow-release agent

A chlorine dioxide technology for fruits and vegetables and chlorine dioxide, which is applied in the field of fresh-keeping materials, can solve the problems of no sterilization effect, unsustainable fresh-keeping effect, poor fresh-keeping effect, etc., and achieve the effects of ensuring safety and sanitation, delaying volatilization, and extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of chlorine dioxide fruit and vegetable fresh-keeping slow-release agent of the present invention comprises the following steps:

[0043] S1. Preparation of miscible product A: Put the chlorine dioxide main agent and part of the reducing agent into the mixing tank, heat up to 50-55°C, start stirring, mix and dissolve for 15-20 minutes, and cool down to room temperature to obtain the miscible product A;

[0044] S2. Preparation of miscible material B: Put the compound control agent and water into another mixing tank according to the metering, raise the temperature to 50-55°C, start stirring, carry out mixing and dissolving for 15-20 minutes, and cool down to room temperature to obtain the miscible material B;

[0045] S3. Preparation of miscible C: put the acidulant and water into the dissolution tank according to the metered amount, raise the temperature to 40-60° C., start stirring, carry out mixing and dissolving for 15-20 minutes, and cool down...

Embodiment 2

[0057] The application of the chlorine dioxide fruit and vegetable fresh-keeping slow-release agent of the present invention is to apply the prepared chlorine dioxide fruit and vegetable fresh-keeping slow-release agent to the fresh-keeping film, and the application method comprises:

[0058] S1: Mix polyvinyl alcohol, starch, and glycerin in water to obtain an insoluble PVA film by casting method, and make a flat bag;

[0059] S2: Put the chlorine dioxide solution into a PVA insoluble bag and seal it, and use the hydrophilic swelling property of PVA to adsorb the chlorine dioxide stable liquid.

[0060] Further, the parts by weight of raw materials for preparing the insoluble PVA film are: 80 parts of polyvinyl alcohol, 15 parts of starch, and 5 parts of glycerin.

[0061] The performance of PVA film prepared by adopting this ratio is excellent.

[0062] Further, the thickness of the insoluble PVA film is 50 μm.

[0063] When the thickness of PVA film is 50μm, it is more su...

experiment example 1

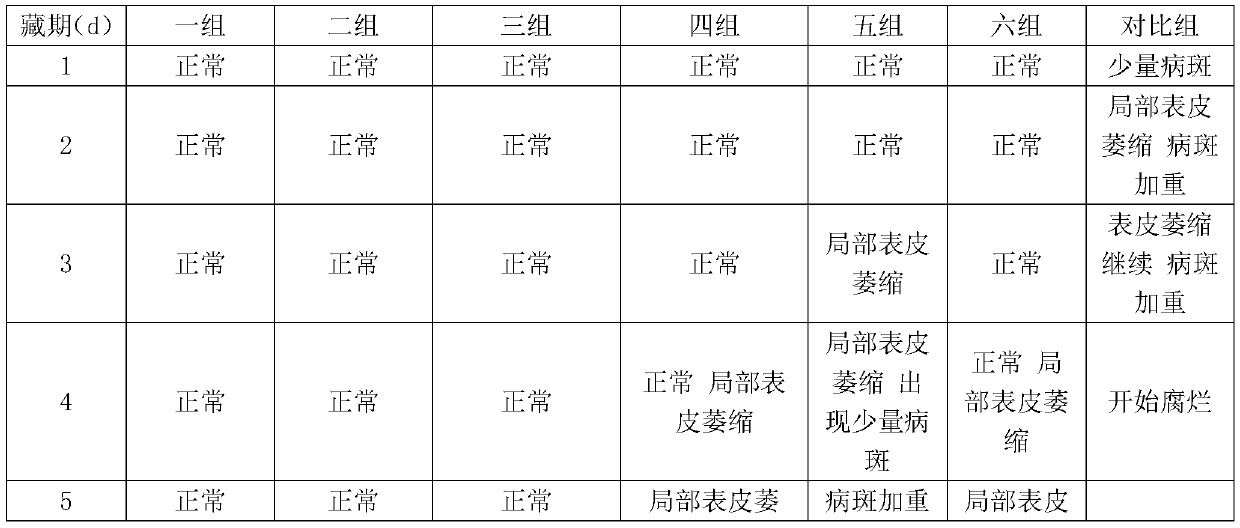

[0065] Experiment content: get the same batch of bananas whose ripeness is more than 95%, adopt the chlorine dioxide slow-release agent in the embodiment 1 of different concentrations and the PVA film after applying the chlorine dioxide slow-release agent in the embodiment 2 to treat the bananas respectively. Preservation treatment, and observe the changes at room temperature, and give a comparison example: the changes of bananas at room temperature in the natural state.

[0066] Experimental purpose: the effect of the PVA film after the application of the chlorine dioxide slow-release agent in the detection embodiment 1 and the application of the chlorine dioxide slow-release agent treatment on the freshness of bananas.

[0067] Experimental materials and methods:

[0068] (1) The preparation concentration is the first group after the PVA film treated with the chlorine dioxide slow-release agent is used for fresh-keeping of bananas.

[0069] (2) Prepare the PVA film with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com