Production line calibration method, device and system of equipment clock, self-calibration method, and equipment

A technology of equipment clock and calibration method, which is applied to clocks, timing pulses, electronic timers, etc., can solve the problems of not being able to reach GPS, not being able to locate satellites, and large frequency deviation, and achieve the effect of eliminating frequency errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] According to the background technology, the clock source of the existing GPS module is TCXO or DCXO, among which, the cost of TCXO is relatively high; and DCXO cannot solve the dynamic error caused by the frequency drift with the temperature change, thus making the positioning of the GPS module inaccurate .

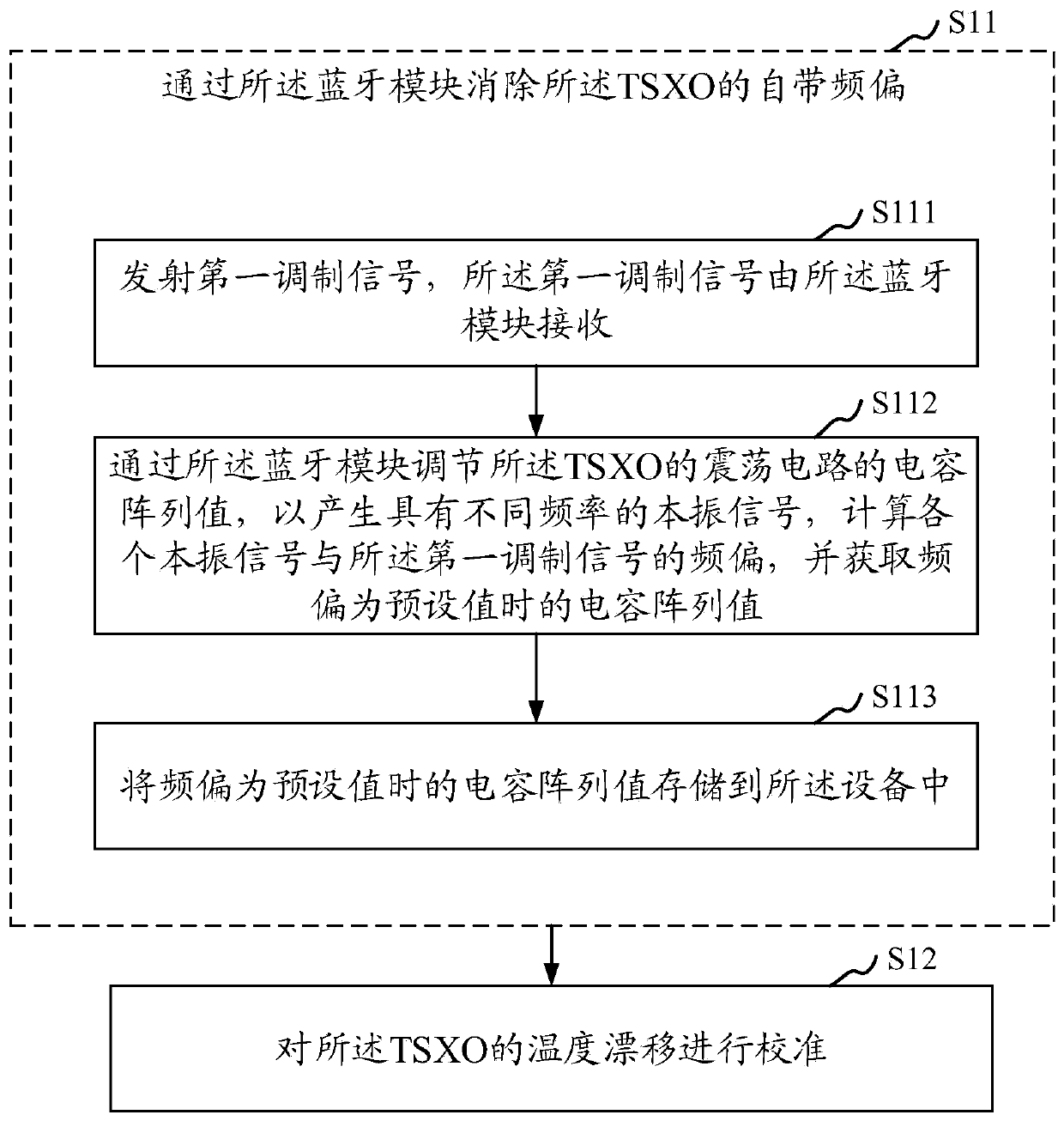

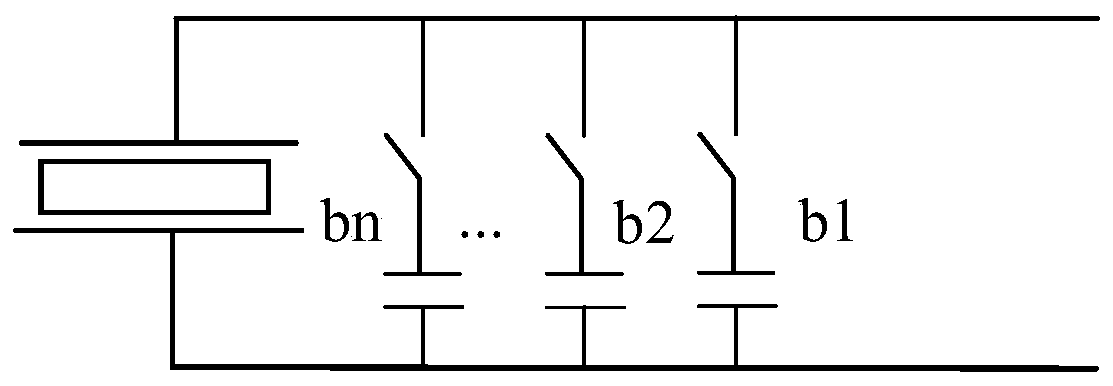

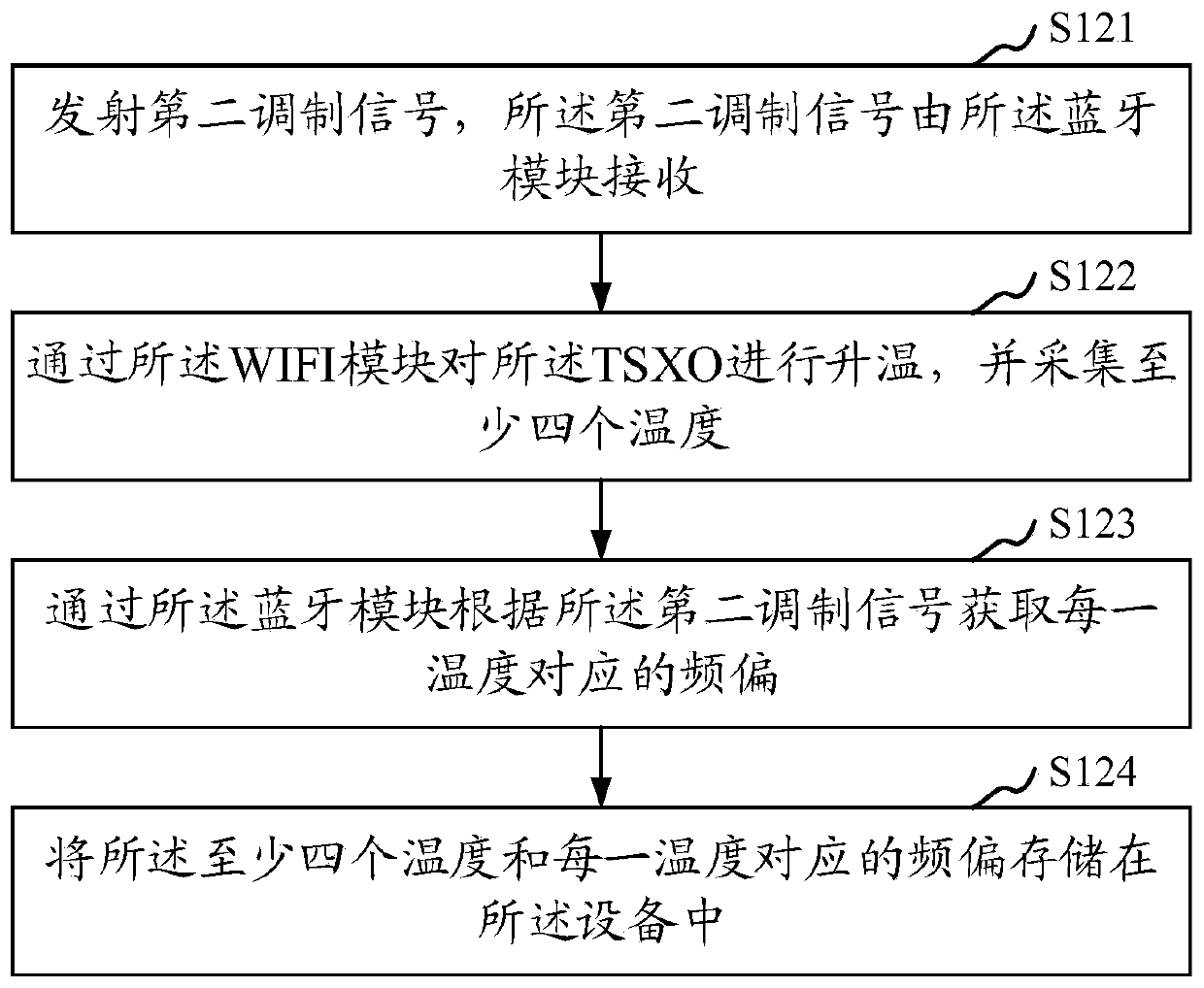

[0035] To address the above problems, a Temperature Sensor Crystal Oscillator (TSXO) can be used to provide a clock for the device. The difference between a TSXO and an ordinary crystal oscillator (Crystal Oscillator) is that the TSXO contains a temperature sensor inside. The temperature sensor is a thermistor or Temperature diodes. At the same time, unlike TCXO, TSXO performs closed-loop feedback control on the output frequency. The output frequency of TSXO is not temperature compensated, which makes the frequency of TSXO output greatly affected by temperature. However, the clock corresponding to the crystal oscillator is required to be accurate as the reference c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com