Energy-saving and environment-friendly thermal circulation tunnel kiln

It is an energy-saving, environmental-friendly, and heat-cycling technology, which is applied in the types of furnaces, waste heat treatment, lighting, and heating equipment. It can solve problems such as poor thermal insulation performance, slow circulation speed, and inability to use hot air to increase operating efficiency and improve heating. Circulation speed, effect of improving circulation heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

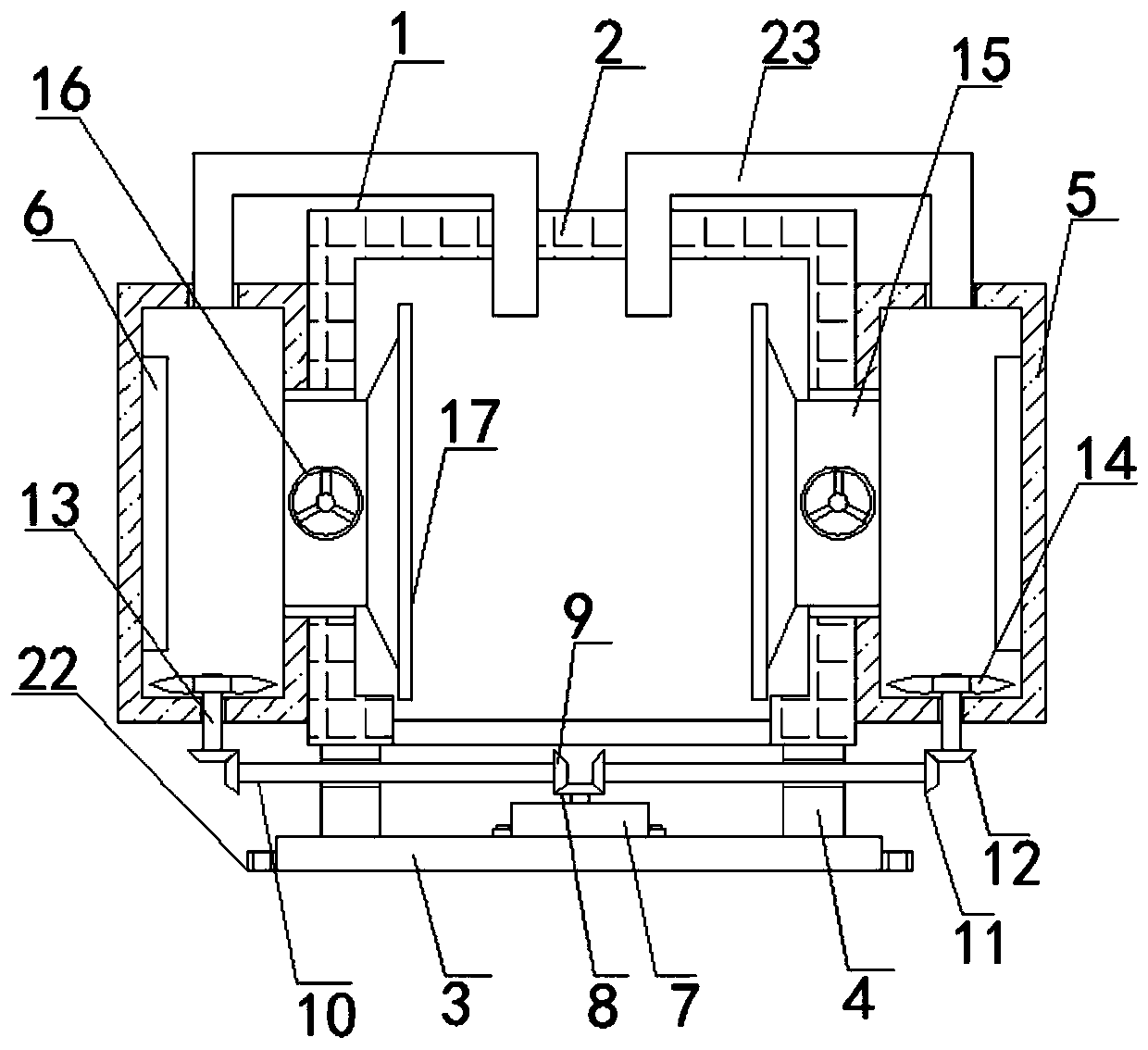

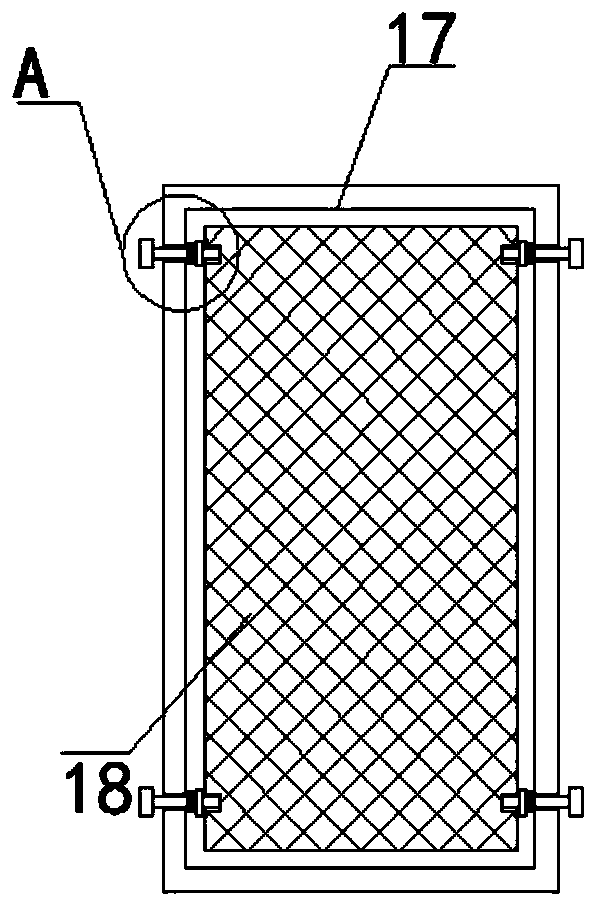

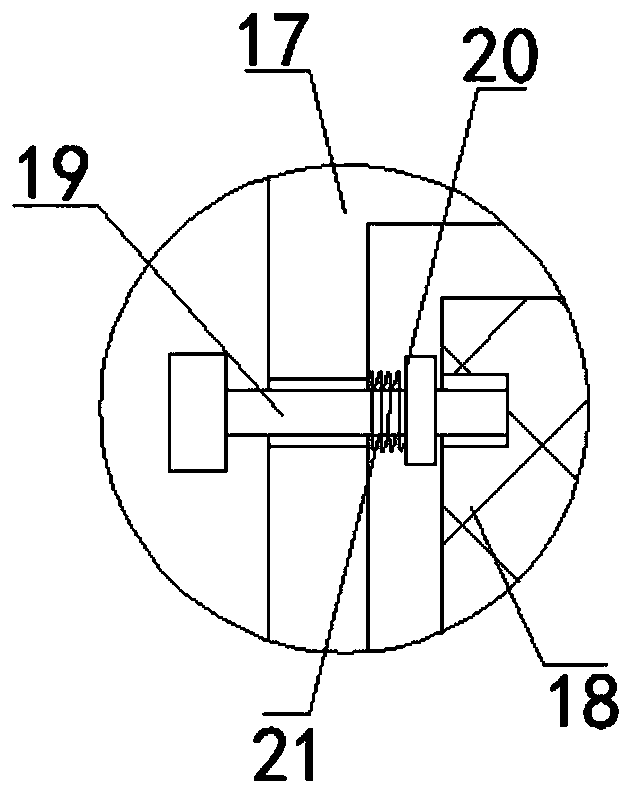

[0023] refer to Figure 1-3 , an energy-saving and environment-friendly thermal cycle tunnel kiln, comprising a kiln frame 1, a brick wall 2 is fixedly connected inside the kiln frame 1, and a mounting plate 3 is provided under the kiln frame 1, and the installation plate 3 and the kiln frame 1 are symmetrically arranged A plurality of support plates 4 are fixedly connected, both sides of the kiln frame 1 are fixedly connected with a heating box 5, the inner wall of the heating box 5 is fixedly connected with a heating plate 6, and the top of the heating box 5 is inserted with a gas delivery pipe 23, and the gas delivery pipe 23 One end away from the heating box 5 runs through the brick wall 2 and extends inwardly. The top of the mounting plate 3 is fixedly connected with a motor 7, and the output end of the motor 7 is fixedly connected with a first gear 8, and both sides of the first gear 8 are provided with corresponding gears. Engaged second gear 9, one side of the second g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com