Control system of constant-temperature and constant-humidity air supply device for pharmaceutical equipment

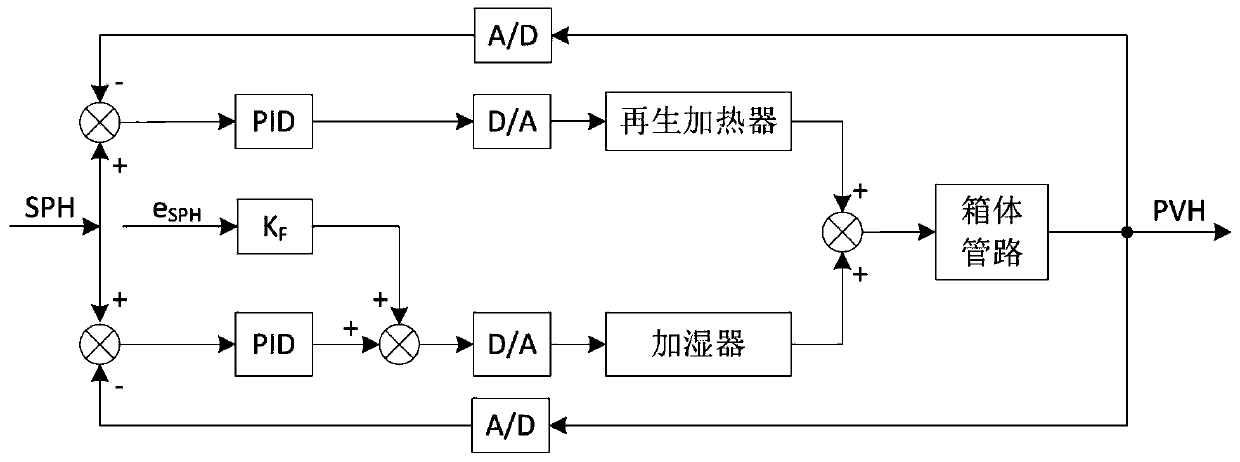

A control system and air supply device technology, applied in lighting and heating equipment, drying gas arrangement, drying, etc., can solve the problems of low control precision, inability to track, fluctuation of humidity control process, etc., to improve control precision and tracking Performance, Effects of Fast Track Control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

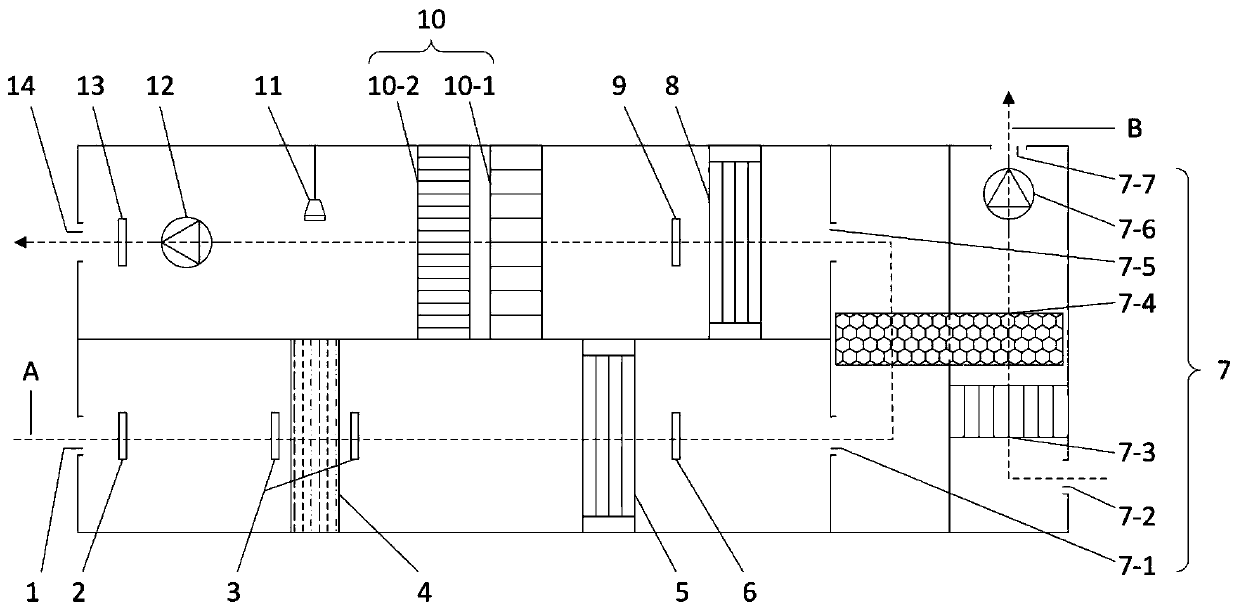

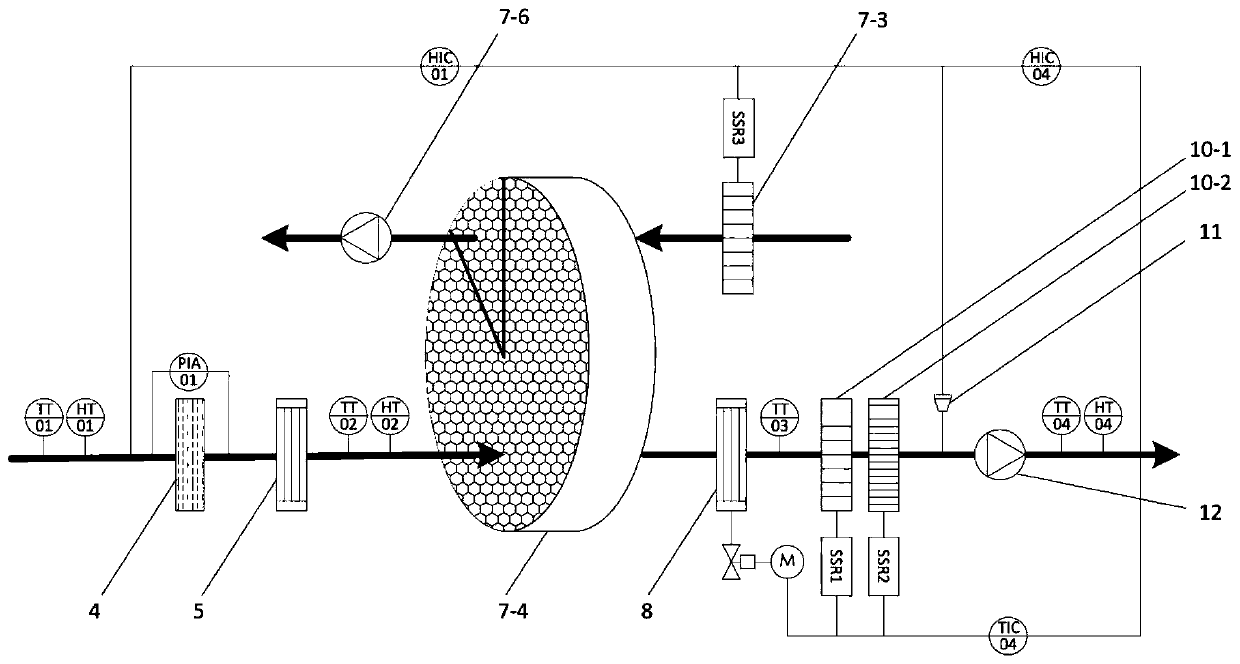

[0061] During the implementation of the present invention, the wind source (i.e. inlet wind) of the constant temperature and humidity air supply device is natural wind, and the output (i.e. outlet air) is constant temperature and humidity wind, which is supplied to equipment such as pharmaceutical fluidized beds. The constant temperature and humidity air supply device is composed of a rotary dehumidifier, a cabinet and pipelines, among which the cabinet is a two-layer structure. The lower layer of the cabinet is from left to right according to the wind flow direction, respectively, the air inlet, the inlet air temperature and humidity sensor, the pressure difference sensor, the filter, the front surface cooler, and the front surface cooling temperature and humidity sensor; the upper layer of the cabinet is from the right according to the wind flow direction. To the left are the rear surface cooler, rear surface cooling temperature sensor, rear heater, humidifier, air supply fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com