A construction method for bracketless suspension and locking of prefabricated segmental box girder

A prefabricated, bracket-free technology, used in the erection/assembly of bridges, bridges, bridge construction, etc., can solve problems such as large restrictions, and achieve the effect of firm anchoring, flexible and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

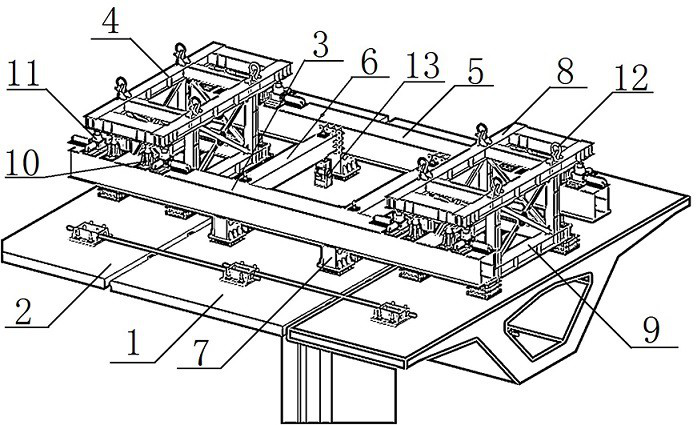

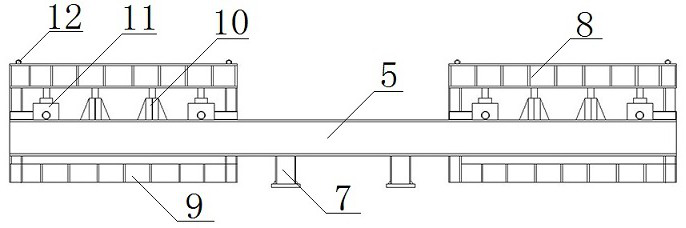

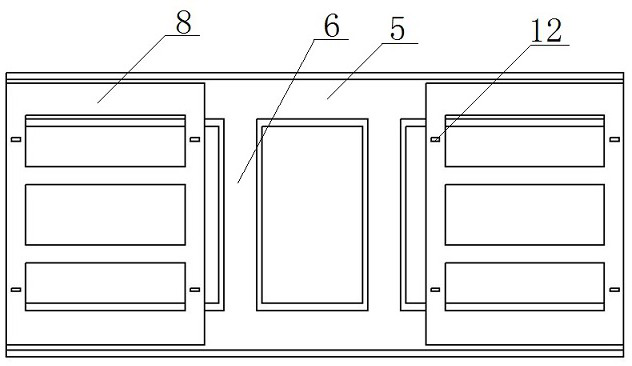

[0031] The following is a further detailed description of a prefabricated segmental box girder suspension and locking construction method of the present invention in combination with the accompanying drawings and specific implementation methods:

[0032] as follows figure 1 and 2 As shown, the suspension beam system used for the hoisting of the prefabricated segmental box girder in the present invention includes a suspension beam 3 fixed on the top surface of the zero block 1 on the top of the pier, and a suspension beam 3 supported on the top surface of the suspension beam 3 by a support adjustment mechanism. Frame 4, the lower end of the hanger 4 is fixed to the prefabricated segmental box girder 2, and the three-dimensional coordinates of the hanger 4 are adjusted through the support adjustment mechanism, so that the hanger 4 can be accurately adjusted relative to the suspension frame, thereby realizing the prefabricated segmental box girder 2 Precise adjustment relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com