Fishing silk imitation electrically-embroidered weft-knitted shoe upper material and production method thereof

A production method, fishing silk technology, applied in the field of weft-knitted upper fabrics, can solve the problems of inability to produce breathable upper materials, and achieve the effects of enhancing the sense of technology and fashion, rich layering, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] This embodiment provides a fishing thread imitation electric embroidery weft-knitted shoe upper material and its production method. The embodiment of the present invention adopts a 20-inch 14G double-sided jacquard double-transfer jacquard machine, which includes the following steps:

[0092] Raw material preparation: Prepare the front layer raw material of shoe upper material, Baiyouguang 110D / 1F polyester fishing thread, feed 1 strand from No. 5 and No. 6 yarn feeders, and connect 2 strands from No. 1 and No. 5 routes; prepare jacquard raw materials for shoe upper material For segment-dyed yarn, one strand is fed from yarn feeders No. 5 and No. 6, and two strands are connected to each of No. 2 and No. No. 6 yarn feeder each feeds 1 strand, and No. 3 and 7 routes are connected to 2 strands;

[0093] Roads 4 and 8 are closed and do not participate in weaving.

[0094] Weaving: On the 20-inch 14G double-sided jacquard double-transfer jacquard machine, weave the fishing...

Embodiment 2

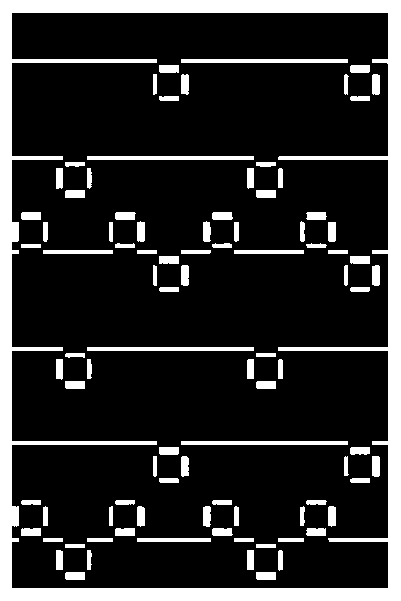

[0138] The difference between the fishing silk imitation electric embroidery weft-knitted shoe upper material and its production method provided in this example and Example 1 is that the raw material for the jacquard part of the upper material is ordinary yarn, and the raw materials are matched according to the graphics and color matching of the computer version. Ground access to the number of yarn feeders, weaving at a speed of 20r / min; get fishing silk imitation electric embroidery weft-knitted shoe upper material white blank such as Figure 7 As shown, the specification is 52.7″, and the weight of the upper material is 474g / m 2 , and finally it is dyed and finished.

[0139] After determination, the performance test results of the fishing silk imitation electric embroidery weft-knitted shoe upper material provided in this embodiment are:

[0140] (1) Water fastness (grade): 5;

[0141] (2) Color shift (level): 5;

[0142] (3) Seam strength (N / cm): 148 in warp direction a...

Embodiment 3

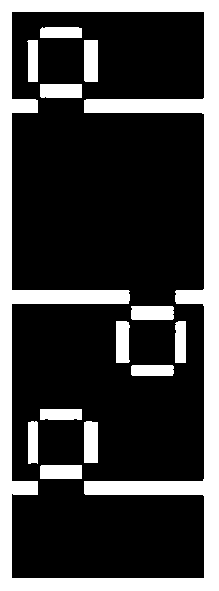

[0148] The difference between the fishing silk imitation electric embroidery weft-knitted shoe upper material and its production method provided in this embodiment and the embodiment 1 is that the raw material for the jacquard part of the upper material is colored yarn, and the raw materials are matched according to the graphics and color matching of the computer version. Ground access to the number of yarn feeders, and weaving at a speed of 18r / min; get fishing silk imitation electric embroidery weft-knitted shoe upper material white blank such as Figure 8 As shown, its specification is 52.7″, and the weight of the upper material is 472g / m 2 , and finally it is dyed and finished.

[0149]After determination, the performance test results of the fishing silk imitation electric embroidery weft-knitted shoe upper material provided in this embodiment are:

[0150] (1) Water fastness (grade): 5;

[0151] (2) Color shift (level): 4;

[0152] (3) Seam strength (N / cm): 150 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com