Throat tube-type airflow drafting device for preparing high-thermal-insulation and flame-retardant material with velvet-like structure

A flame retardant material and drafter technology, applied in textiles and papermaking, etc., can solve the problems of the influence of tow, the adjustment and enlargement of the gap area, etc., and achieve the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

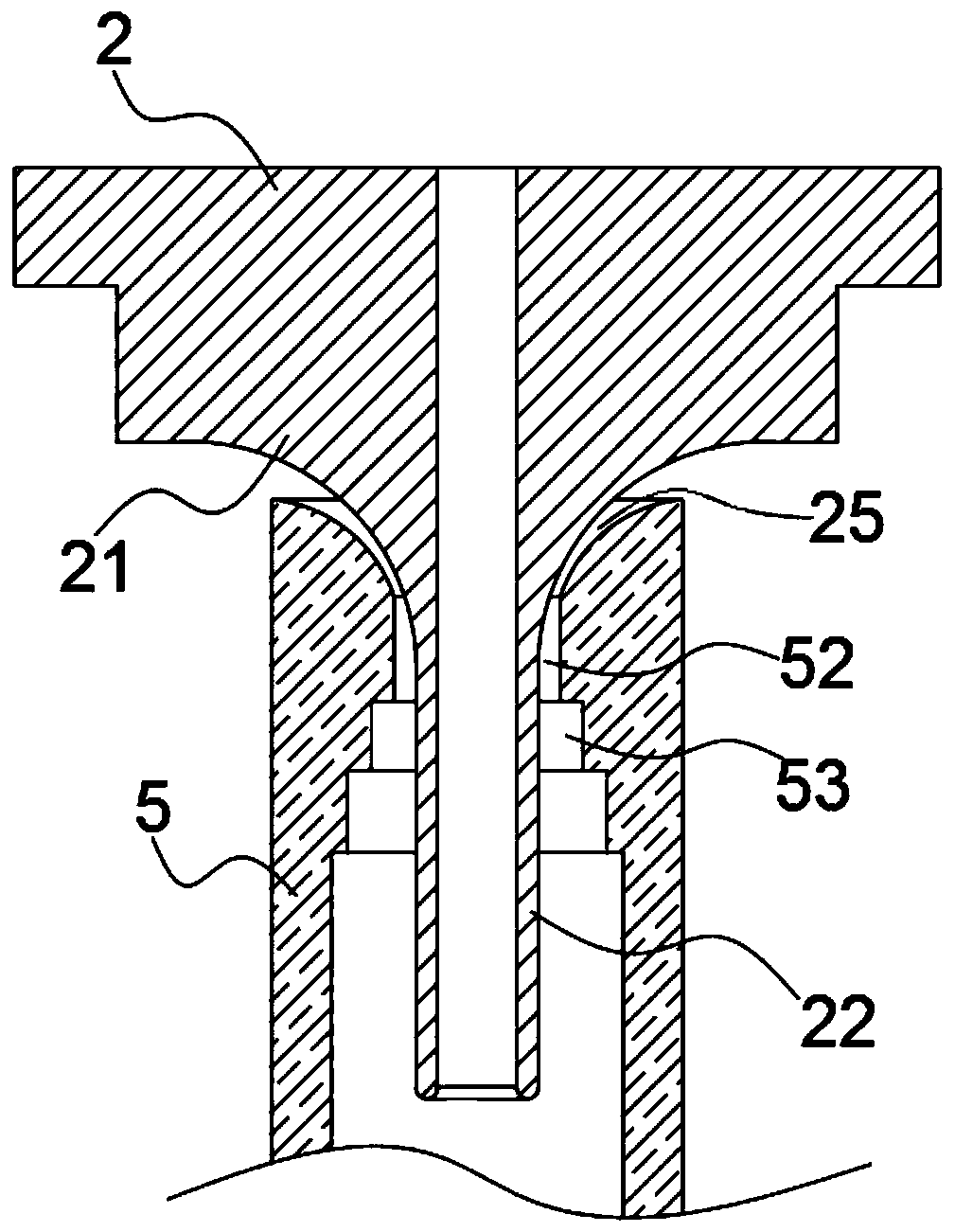

[0020] Such as Figure 1-3 As shown, the throat-type airflow drafter for the preparation of goose down structure high heat-retaining and flame-retardant materials according to the present invention comprises an upper sleeve 1, and the upper end of the upper sleeve 1 is threaded with a drafting cap 2, and the drafting cap 2 and the upper sleeve 1 is provided with a gasket 7, the gasket 7 is made of metal, the thickness is stable, the lower end of the drafting cap 2 is composed of an arc structure 21 and a straight pipe structure 22, by changing the thickness of the gasket 7, the draft can be made The depth at which the cap 2 is screwed into the upper casing 1 is changed.

[0021] The lower part of the upper sleeve 1 is provided with an air inlet 10, and the bottom of the upper sleeve 1 is connected with the lower sleeve 8 by threads, and the bottom of the upper sleeve 1 is provided with a lower plug 4, and the inside of the upper sleeve 1 A central tube 5 is provided, and the ...

Embodiment 2

[0024] Such as Figure 1-3 As shown, the throat-type airflow drafter for the preparation of goose down structure high heat-retaining and flame-retardant materials according to the present invention comprises an upper sleeve 1, and the upper end of the upper sleeve 1 is threaded with a drafting cap 2, and the drafting cap 2 and the upper sleeve 1 is provided with a gasket 7, the gasket 7 is made of metal, the thickness is stable, the lower end of the drafting cap 2 is composed of an arc structure 21 and a straight pipe structure 22, by changing the thickness of the gasket 7, the draft can be made The depth at which the cap 2 is screwed into the upper casing 1 is changed.

[0025] The lower part of the upper sleeve 1 is provided with an air inlet 10, and the bottom of the upper sleeve 1 is connected with the lower sleeve 8 by threads, and the bottom of the upper sleeve 1 is provided with a lower plug 4, and the inside of the upper sleeve 1 A central tube 5 is provided, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com