Radioactive pollution control and removal material and preparation method thereof

A technology of film-forming emulsion and hollow glass microspheres, applied in coatings, conjugated diene coatings, etc., can solve problems such as technical limitations, lead toxicity, and large radiation doses for chemical defense personnel, and achieve shielding and isolation of radioactivity ray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

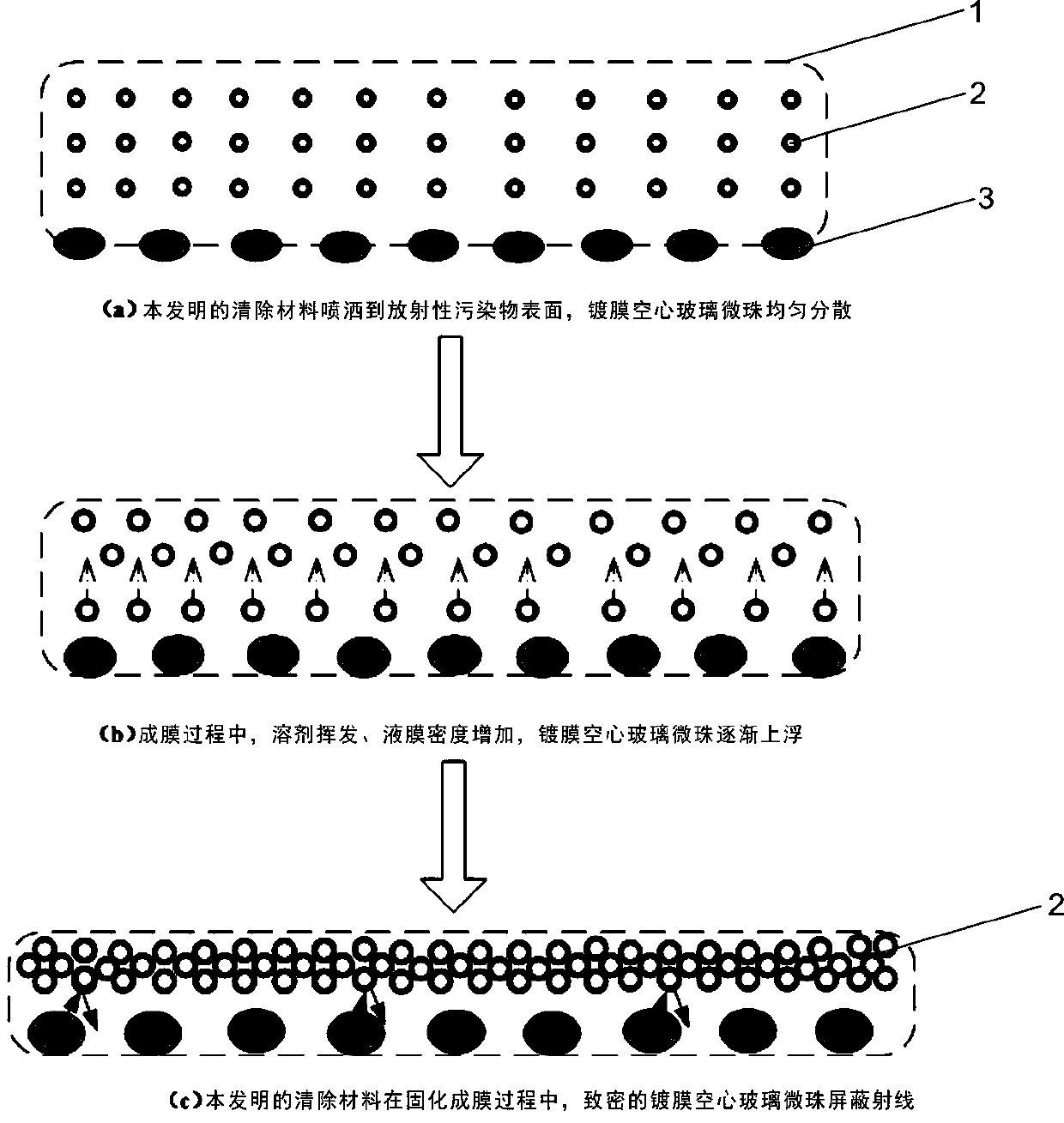

[0024] A radioactive pollution control and removal material is composed of the following components in parts by weight: 60 parts of composite film-forming emulsion, 15 parts of coated hollow glass microspheres, and 0.5 parts of additives.

[0025] The composite film-forming emulsion is formed by mixing acrylate polymer, vinegar-acrylic emulsion, and styrene-butadiene emulsion in a mass ratio of 60:20:10.

[0026] The coated hollow glass microspheres are plated with a layer of 500-5000nm thick barium or tungsten on the outer surface of the hollow glass microspheres by electroless plating, electroplating or magnetron sputtering, and the diameter of the hollow glass microspheres is 100 ~200 μm.

[0027] The additives are non-ionic surfactant and viscosity modifier, wherein the non-ionic surfactant is polyoxyethylene lauryl ether, and the viscosity modifier is alkali-swellable thickener AES-60.

[0028] In order to further improve the radiation shielding ability of the present in...

Embodiment 2

[0031] A radioactive pollution control and removal material, which consists of the following components in parts by weight: 70 parts of composite film-forming emulsion, 23 parts of coated hollow glass microspheres, and 3 parts of additives.

[0032] The composite film-forming emulsion is formed by mixing acrylate polymer, vinegar-acrylic emulsion, and styrene-butadiene emulsion in a mass ratio of 60:30:15.

[0033] The coated hollow glass microspheres are plated with a layer of 500-5000nm thick barium or tungsten on the outer surface of the hollow glass microspheres by electroless plating, electroplating or magnetron sputtering, and the diameter of the hollow glass microspheres is 100 ~200 μm.

[0034] The additives are non-ionic surfactant and viscosity modifier, wherein the non-ionic surfactant is polyoxyethylene lauryl ether, and the viscosity modifier is alkali-swellable thickener AES-60.

[0035] In order to further improve the radiation shielding ability of the present ...

Embodiment 3

[0037] A radioactive pollution control and removal material, which consists of the following components in parts by weight: 80 parts of composite film-forming emulsion, 30 parts of coated hollow glass microspheres, and 5 parts of additives.

[0038] The composite film-forming emulsion is formed by mixing acrylate polymer, vinegar-acrylic emulsion, and styrene-butadiene emulsion in a mass ratio of 60:40:20.

[0039] The coated hollow glass microspheres are plated with a layer of 500-5000nm thick barium or tungsten on the outer surface of the hollow glass microspheres by electroless plating, electroplating or magnetron sputtering, and the diameter of the hollow glass microspheres is 100 ~200 μm.

[0040] The additives are non-ionic surfactant and viscosity modifier, wherein the non-ionic surfactant is polyoxyethylene lauryl ether, and the viscosity modifier is alkali-swellable thickener AES-60.

[0041] In order to further improve the radiation shielding ability of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com