Pavement patching material and preparation method thereof

A pavement repair and manganese slag technology, applied in the field of pavement repair materials and preparation, can solve the problems of high cost, slow early strength of repair materials, long open traffic time, etc., to reduce production costs, facilitate implementation, and open traffic time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

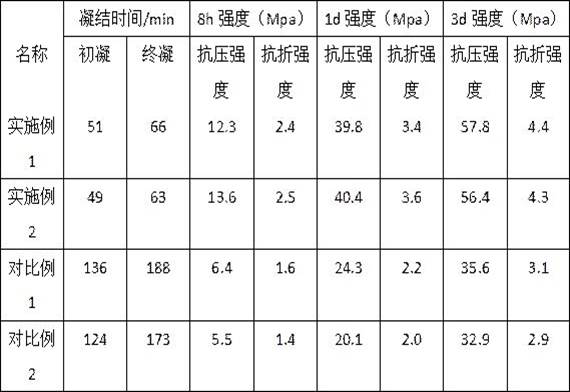

Examples

Embodiment 1

[0029] In the present embodiment, the technical solution of the pavement repair material is:

[0030] A pavement repair material, wherein, by weight, comprising 58 parts of manganese slag, 42 parts of red mud, 27 parts of alkaline excitant, 6 parts of 600 mesh silica ash, 30 parts of calcium oxide, 14 parts of water; the alkaline excitant comprises potassium hydroxide and potassium water glass, the weight ratio is 1: 3, the modulus of potassium water glass is 2.7.

[0031] The preparation method of the above pavement repair material, wherein it is characterized, comprises the following steps:

[0032] S1, the manganese slag and red mud after mixing for calcination, calcination temperature of 650 °C, calcination time of 2.6h, after cooling to get mixture A, standby;

[0033] S2, the mixture A for ball milling, ball milling time is 2.4h, after ball grinding, sieving, sieving size of 0.15mm, sieve rate of more than 95%, to obtain mixture B;

[0034] S3, the mixture B and alkaline excit...

Embodiment 2

[0036] In the present embodiment, the technical solution of the pavement repair material is:

[0037] A pavement repair material, wherein, by weight, comprising 62 parts of manganese slag, 48 parts of red mud, 26 parts of alkaline excitant, 5 parts of 600 mesh silica ash, 29 parts of calcium oxide, 13 parts of water; the alkaline excitator comprises potassium hydroxide and potassium water glass, the weight ratio is 1: 2, the potassium water glass modulus is 2.7.

[0038] The preparation method of the above pavement repair material, wherein it is characterized, comprises the following steps:

[0039] S1, the manganese slag and red mud after mixing for calcination, calcination temperature of 650 °C, calcination time of 2.6h, after cooling to get mixture A, standby;

[0040] S2, the mixture A for ball milling, ball milling time is 2.4h, after ball grinding, sieving, sieving size of 0.075mm, sieving rate of more than 85%, to obtain mixture B;

[0041] S3, the mixture B and alkaline ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com