A stackable light pole rack

A placing rack and stacking technology, applied in the field of stacking light pole placement racks, can solve the problems of light pole collision damage, light pole rolling, falling, etc., so as to avoid force shaking and mutual collision, and avoid rolling and collision. problems, the effect of improving the utilization of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

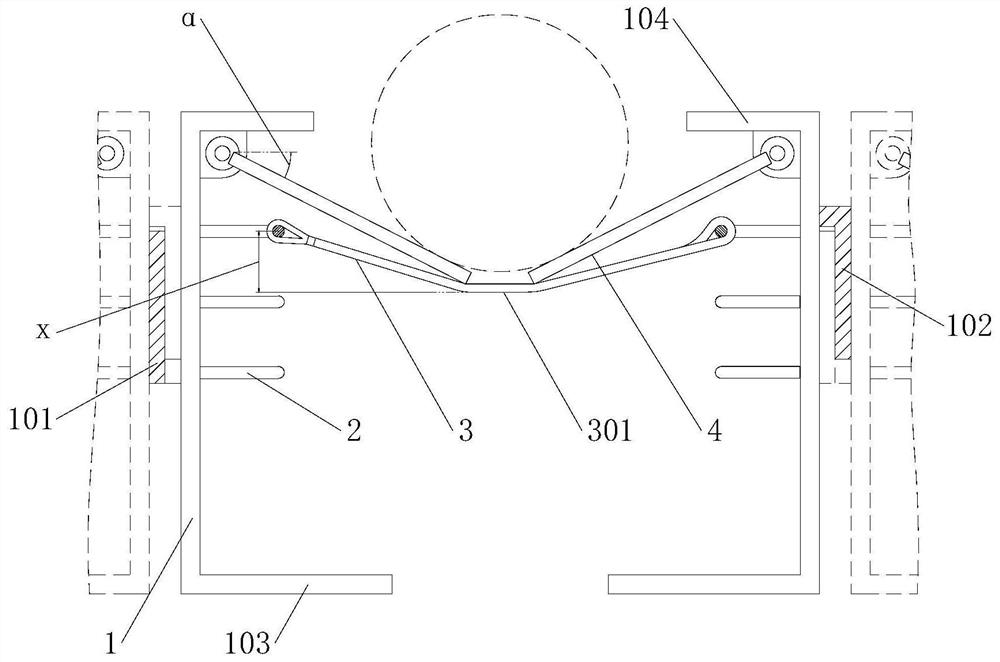

[0021] Example. A stacked light pole placement frame, constituted as figure 1 As shown, it includes a left-right symmetrical placement frame 1, and a plurality of installation ring groups are arranged at intervals from top to bottom in the placement frame 1, and each group of installation ring groups includes installation rings 2 respectively arranged on the inner sides of the two placement frames 1, The two installation rings 2 of one group of installation ring groups are connected to each other through a steel wire rope 3, and the steel wire rope 3 is wound on the installation ring 2 in multiple turns. The bottom of the plate 4 is attached to the wire rope 3; the outer wall of the shelf 1 on one side is provided with a buckle groove 101, and the outer wall of the shelf 1 on the other side is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com