Hydraulic system

A hydraulic system and pump system technology, applied in the field of hydraulic systems, can solve the problems of hydraulic systems such as unreliability, failure-prone, and expensive, and achieve cost-effectiveness, reduce pump drive torque, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

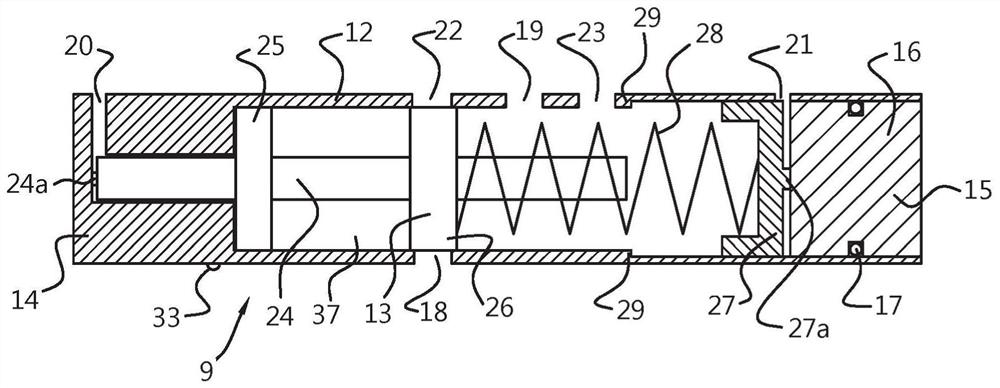

[0035] In the drawings, the drawings are only given as schematic illustrations of the invention. Corresponding elements are indicated with corresponding reference numerals.

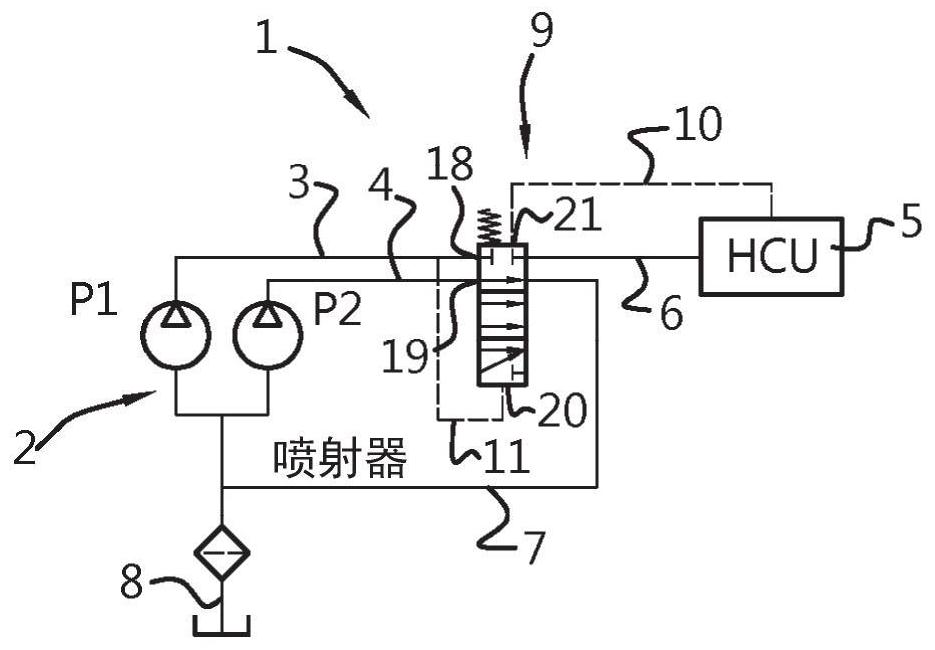

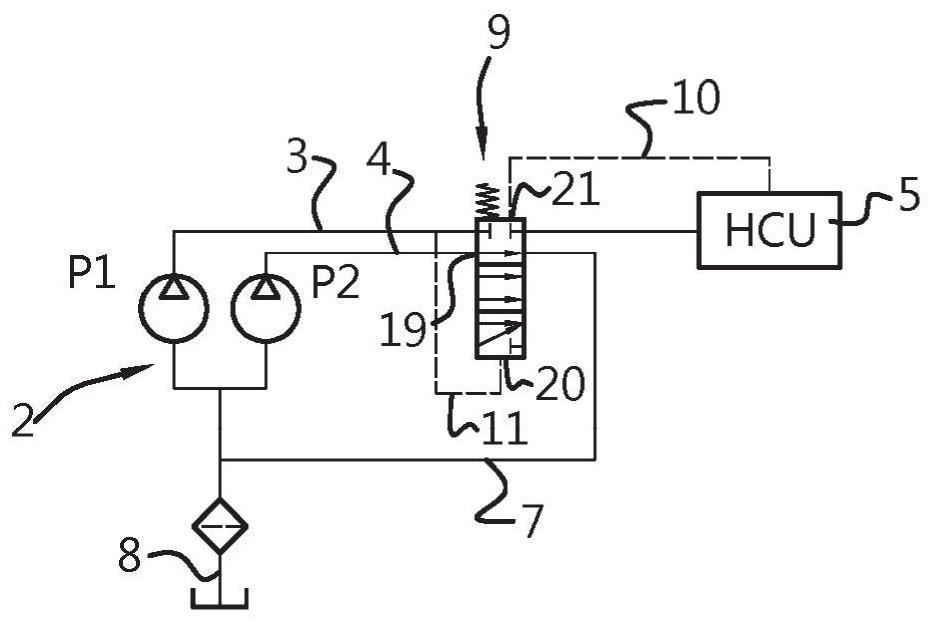

[0036] Figure 1A A part of a hydraulic diagram of a hydraulic system 1 for a vehicle transmission is shown. The hydraulic system 1 comprises a pump system 2 comprising two pumps or pump chambers P1 and P2 with at least two outlet lines 3, 4 for supplying hydraulic fluid via a supply line 6 to Hydraulic Control Unit (HCU)5. The hydraulic control unit 5 is generally configured to provide line pressure to control the hydraulic pressure on the friction elements of the vehicle transmission.

[0037] The pump system 2 has a bypass circuit 7 arranged to provide a reduced pressure therein when the bypass circuit is opened to allow flow through one of the outlet lines 3 , 4 . Furthermore, a sump 8 is provided in which drained hydraulic fluid can be received and from which the pump system 2 can be supplied with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com