Online monitoring method for full life cycle of transformer substation direct-current system based on Internet of Things

A full-life-cycle, DC-system technology, applied in the field of online monitoring of the full-life-cycle DC system of substations, can solve the problems of inconvenient maintenance, long maintenance cycle for a single battery or charger, and low efficiency, so as to improve maintenance efficiency, The effect of shortening the equipment maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

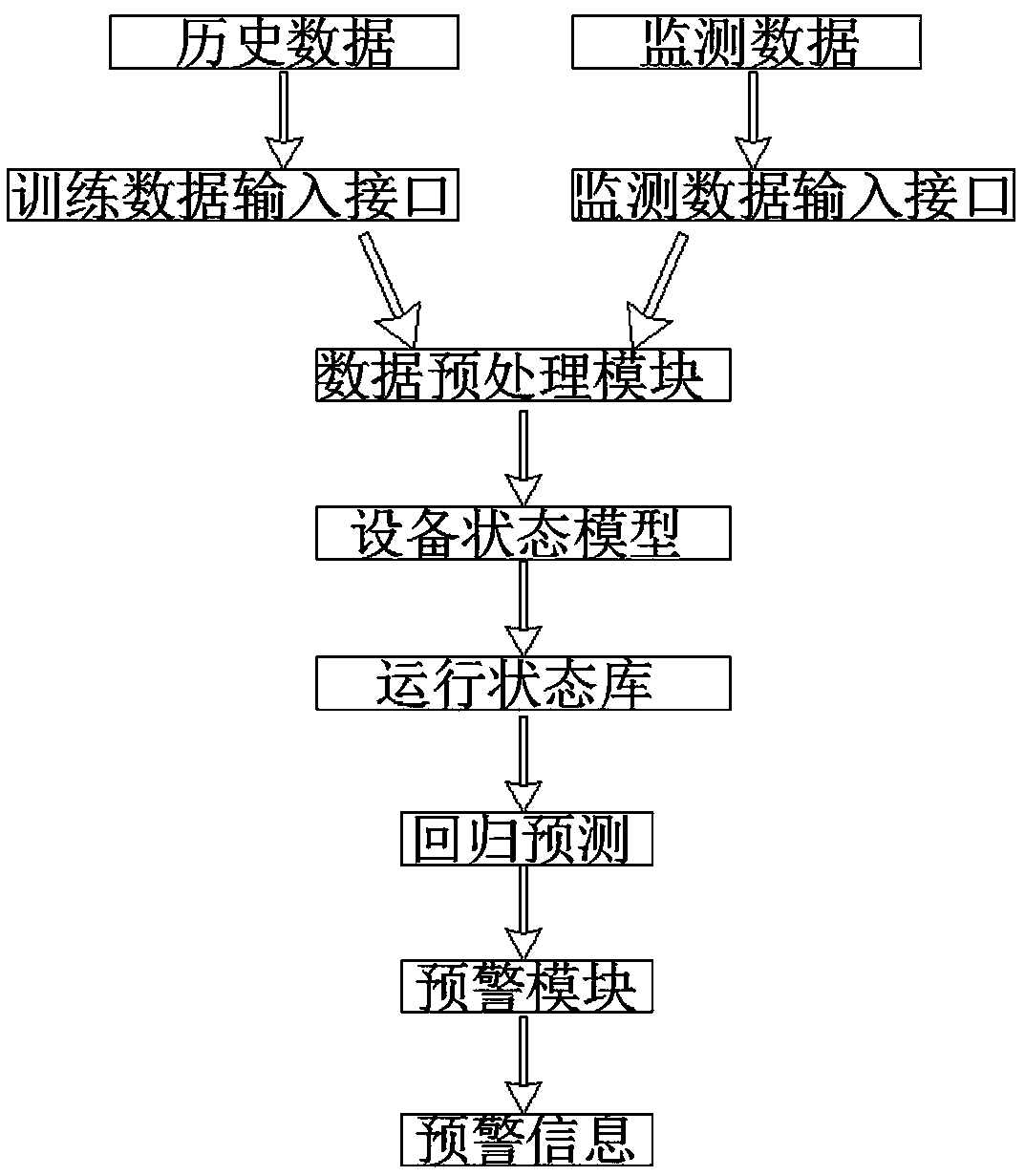

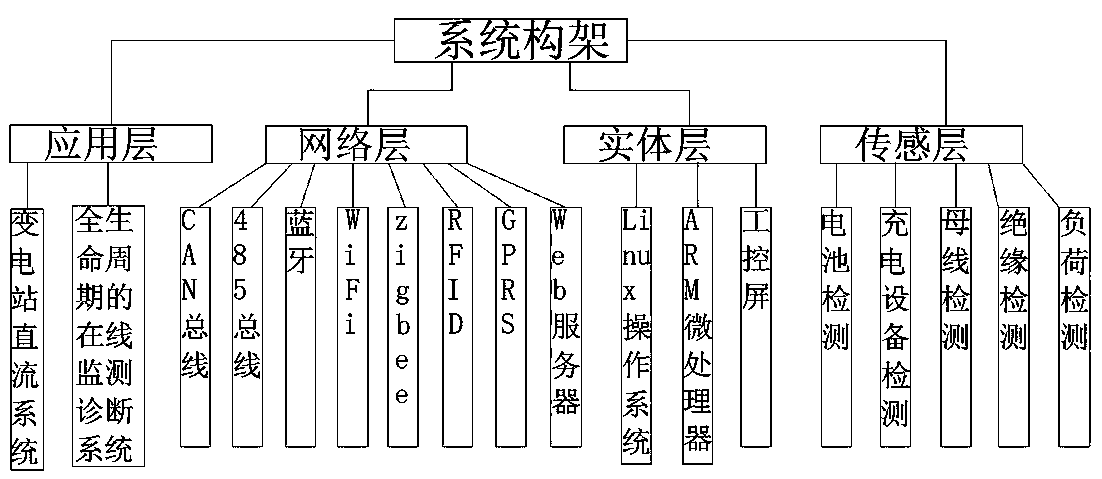

[0030] refer to Figure 1-2 , an online monitoring method for the whole life cycle of a substation DC system based on the Internet of Things, including the following steps:

[0031] S1: Collect historical data and monitoring data, conduct comprehensive judgment on system status through historical data analysis, and monitor DC system operating parameters and actual equipment working conditions;

[0032] S2: Pass the collected historical data and monitoring data into the training data input interface and the monitoring data input interface respectively;

[0033] S3: Pass various data into the data preprocessing module for preprocessing, and use the Internet of Things to realize system interconnection;

[0034] S4: Analyze the equipment state model, automatically handle some abnormalities in the DC system through the results of processing the input data, judge the operating status of the DC system according to the on-site operating parameters, and perform corresponding adjustmen...

Embodiment 2

[0042] refer to Figure 1-2 , an online monitoring method for the whole life cycle of a substation DC system based on the Internet of Things, including the following steps:

[0043] S1: Collect historical data and monitoring data, conduct comprehensive judgment on system status through historical data analysis, and monitor DC system operating parameters and actual equipment working conditions;

[0044] S2: Pass the collected historical data and monitoring data into the training data input interface and the monitoring data input interface respectively;

[0045] S3: Pass various data into the data preprocessing module for preprocessing, and use the Internet of Things to realize system interconnection;

[0046] S4: Analyze the equipment state model, automatically handle some abnormalities in the DC system through the results of processing the input data, judge the operating status of the DC system according to the on-site operating parameters, and perform corresponding adjustmen...

Embodiment 3

[0054] refer to Figure 1-2 , an online monitoring method for the whole life cycle of a substation DC system based on the Internet of Things, including the following steps:

[0055] S1: Collect historical data and monitoring data, make a comprehensive judgment on the system status through historical data analysis, monitor the operating parameters of the DC system and the actual equipment working conditions, and realize "prescribing the right medicine".

[0056] S2: Pass the collected historical data and monitoring data into the training data input interface and the monitoring data input interface respectively.

[0057] S3: Pass all kinds of data into the data preprocessing module for preprocessing, and use the Internet of Things to realize system interconnection and help the smart grid.

[0058] S4: Analyzing the equipment state model can automatically handle some abnormal situations of the DC system, judge the operating status of the DC system according to the operating para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com