Fiber bragg grating wind speed and direction sensor

A fiber grating, wind speed and direction technology, applied in instruments, fluid velocity measurement, optical devices, etc., can solve the problem of not taking into account the temperature of the measurement equipment, components damage accuracy, low precision, etc., to reduce component loss, reduce Small collision effect, the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions, and advantages of the present application clearer, the embodiments of the present application will be described in detail below with reference to the accompanying drawings. It should be noted that the embodiments in this application and the features in the embodiments can be combined with each other arbitrarily if there is no conflict.

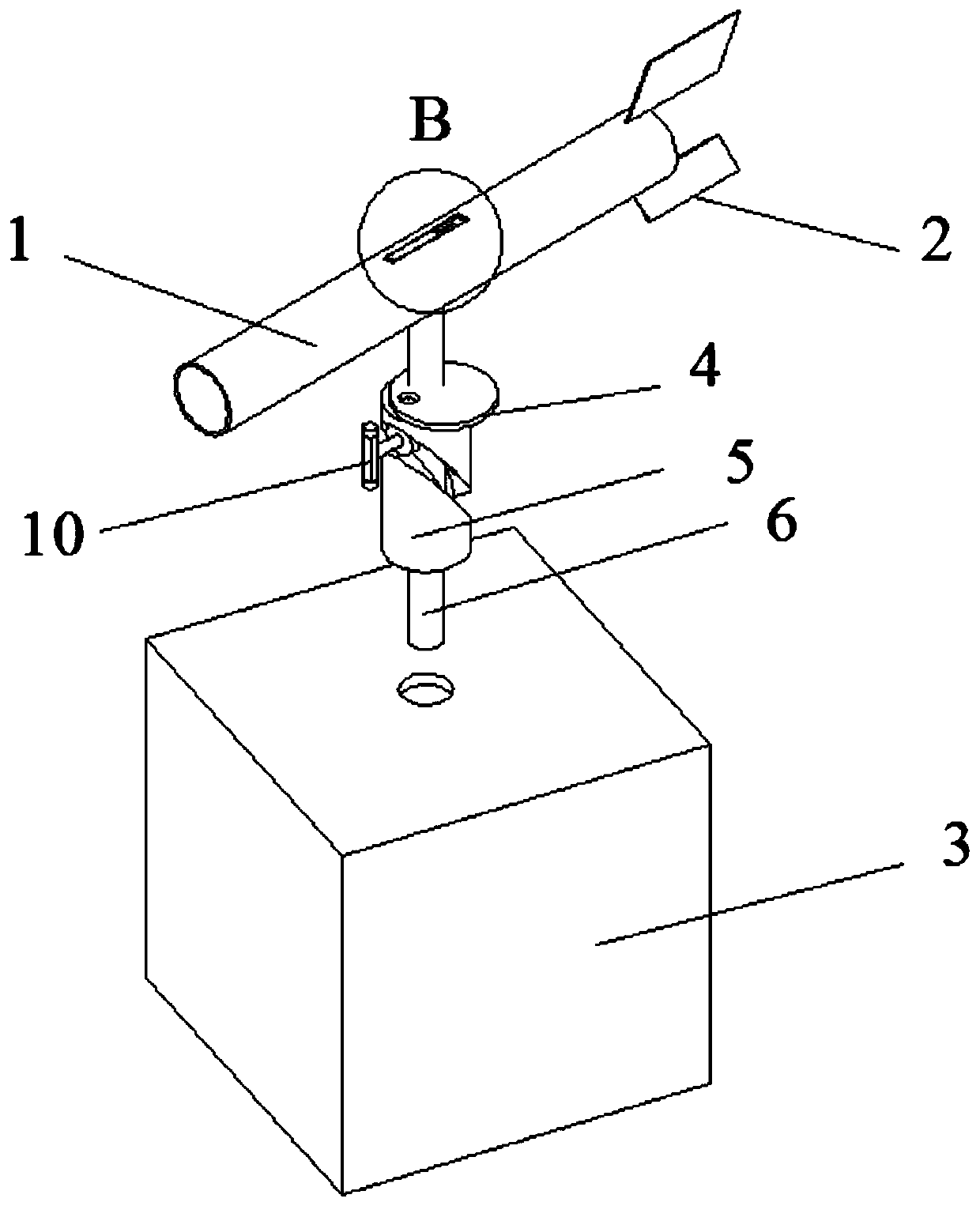

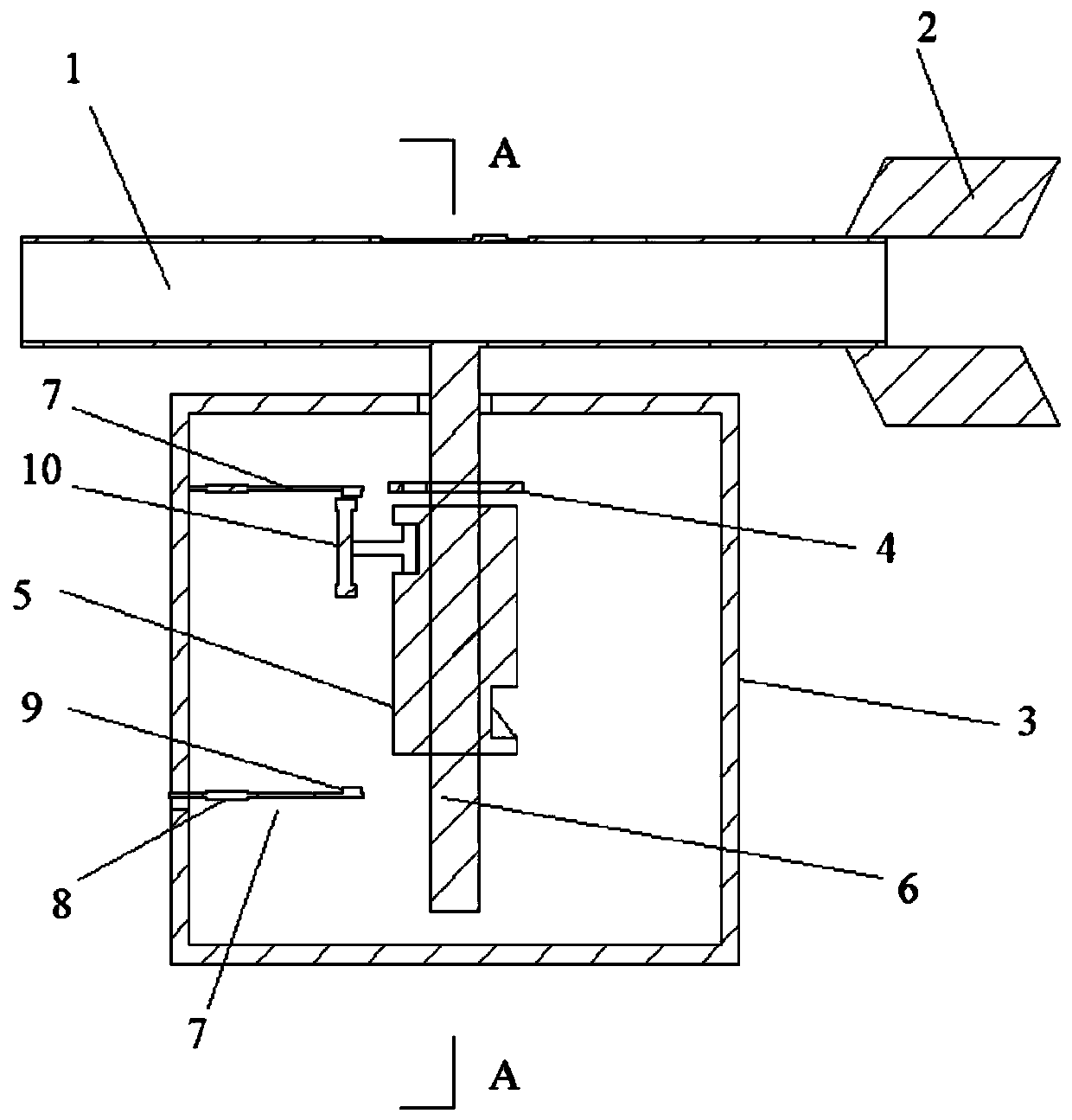

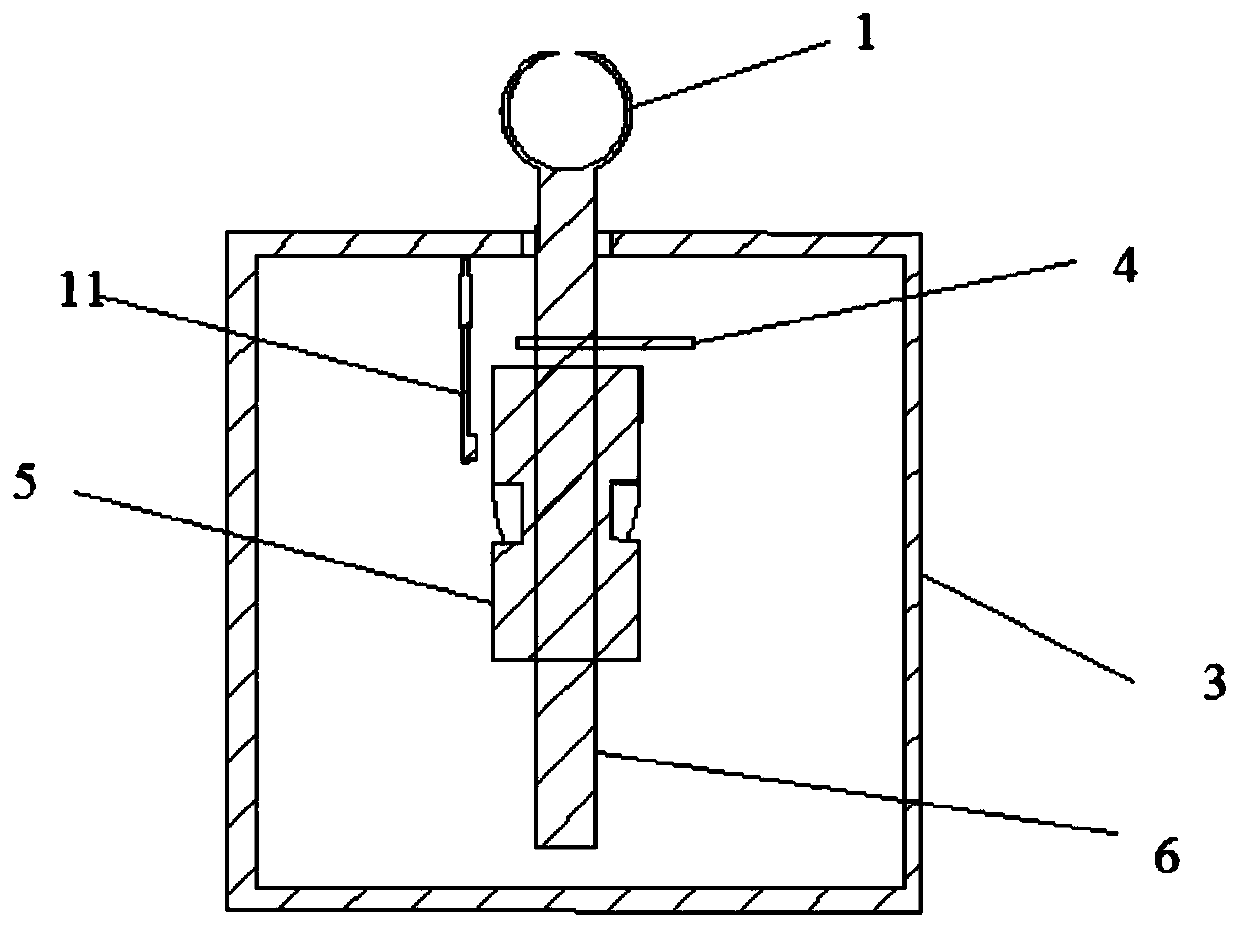

[0026] Such as figure 1 with 2 As shown, the schematic diagram of the structure of the fiber grating wind speed and direction sensor according to the present application is shown. The fiber grating wind speed and direction sensor of the present application includes a thin-walled cylinder 1 and a package body 3. The thin-walled cylinder 1 is connected with a rotating shaft 6 and is arranged above the package body 3 through the rotating shaft 6. Preferably, the rotating shaft 6 can be fixed in the mounting hole above the package 3 through a bearing. Both ends of the thin-walled cylinder 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com