Phased array ultrasonic detection method for welding buoy bottom plate and sampan

A technology of ultrasonic testing and phased array, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve the problems of high detection sensitivity and achieve high defect detection rates. , to avoid missing defects, to ensure the effect of internal and surface quality

Inactive Publication Date: 2020-04-10

725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The focused sound beam can carry out multi-angle fine scanning, combined with computer modeling technology, it can detect welds with relatively complex structures, with accurate defect identification and high detection sensitivity. At present, this technology has not been used in the inspection of buoy bottom plate and sampan welding structure. There are related reports and research in

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0039] 1. Detection system configuration:

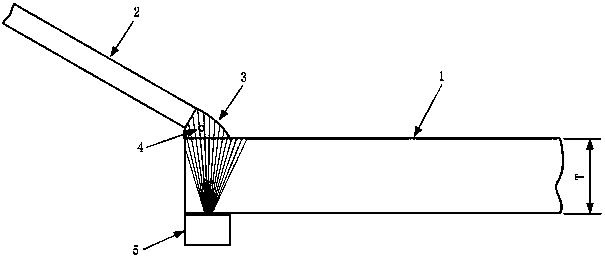

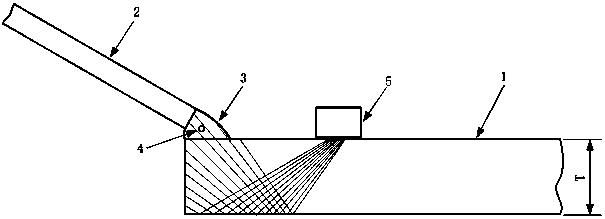

[0040] The thickness of the buoy bottom plate is T=20mm, and the 64:64 channel phased array ultrasonic testing system is selected as the testing equipment. The frequency of the probe 5 is 5MHz, and the wafer is 32×0.5. The probe 5 is connected with the host.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

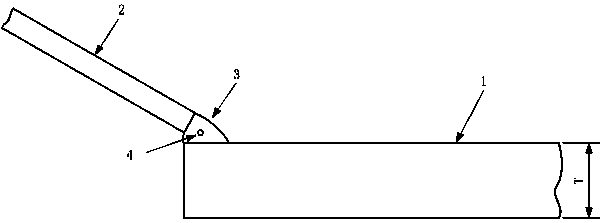

The invention relates to a phased array ultrasonic detection method for welding a buoy bottom plate and a sampan. The method is based on phased array ultrasonic angle gain compensation ACG and time gain compensation TCG. Sensitivity is set by utilizing an artificial transverse hole in a welding seam. An optimal scanning mode is determined through acoustic beam coverage simulation, detection is carried out in a vertical incident fan scanning mode and an oblique incident fan scanning mode, defects are visually displayed, quantified and accurately positioned, the key technical problem of internaldefect detection of the fillet weld of the bottom plate and the sampan is solved, and the detection sensitivity is not lower than phi 1 * 10 mm<-10>dB.

Description

technical field [0001] The invention relates to the technical field of weld detection, in particular to a phased array ultrasonic detection method for the welding of a buoy bottom plate and a sampan. Background technique [0002] Ocean buoys are used to collect ocean hydrology, water quality and meteorological data. Persistence and stability are essential comprehensive performances. However, buoys have been in service in sea conditions for a long time, which puts forward higher requirements for quality control in the integrated construction process. The buoy shell is in direct contact with seawater for a long time, and the quality of welded joints is an important factor affecting the overall quality of the buoy shell. Butt welds in buoy shells are usually inspected by radiography to check the welding quality. However, due to the limitation of inspection space and joint form, the fillet joints cannot be inspected by radiography, and it is difficult to accurately inspect the i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N29/06

CPCG01N29/069G01N29/0609G01N29/043G01N2291/0289G01N2291/267

Inventor 王海登孙奇鄂楠余巍边传新宋德军王伏喜张浩

Owner 725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com