Fuel tank air tightness testing tool and sealing plug pressing tool

An air tightness detection and fuel tank technology, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, etc. Fuel tank air tightness detection, simple structure, and the effect of ensuring the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

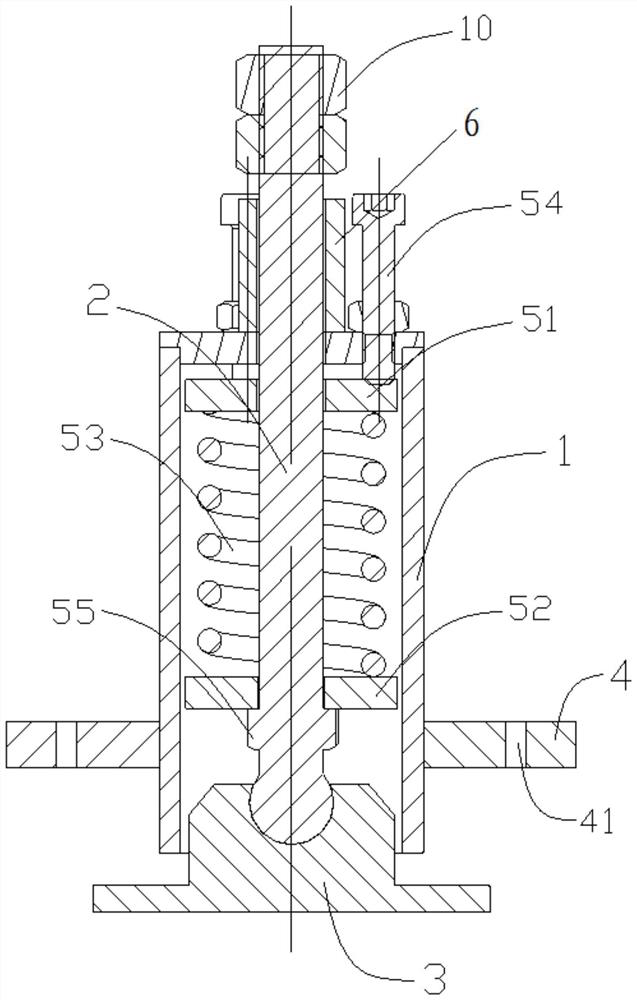

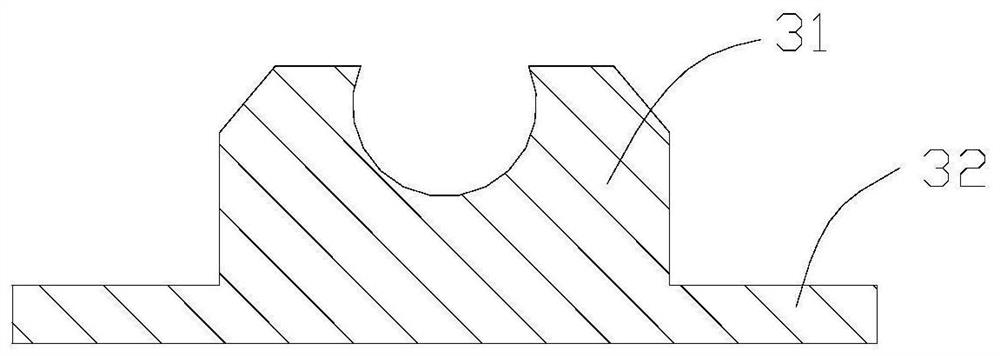

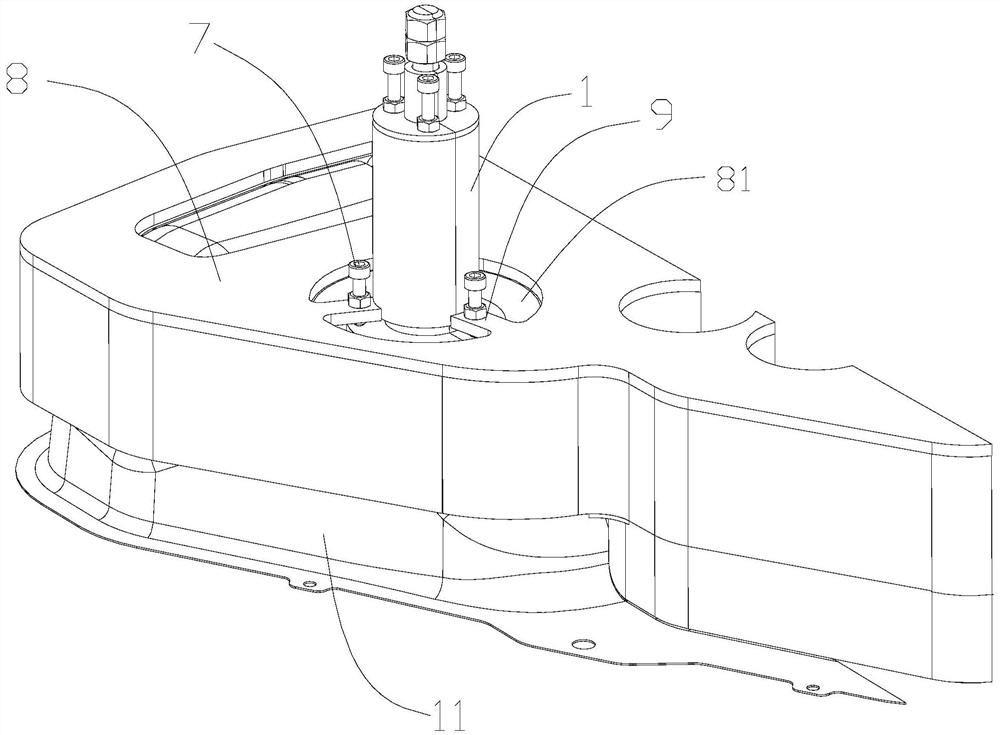

[0024] Such as figure 1 , figure 2 As shown, the compression tooling of the fuel tank air-tightness detection sealing plug of the present invention includes a sleeve 1 with a lower opening, a screw 2, and a joint pressure plate 3. The top of 1 is provided with a first connecting threaded hole, the upper end of the screw rod 2 is matched and set through the first connecting threaded hole, and the lower end of the screw rod 2 is hinged with the joint pressure plate 3 . After the casing 1 is fixed on the clamping upper part 8, by rotating the screw 2, the screw 2 can move up and down in the first connecting threaded hole, the screw 2 drives the joint pressure plate 3 to move up and down, and the rotating screw 2 can also move the sealing plug Compression and adjustment of compression force. The lower end of the screw rod 2 is hinged with the joint pressing plate 3, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com