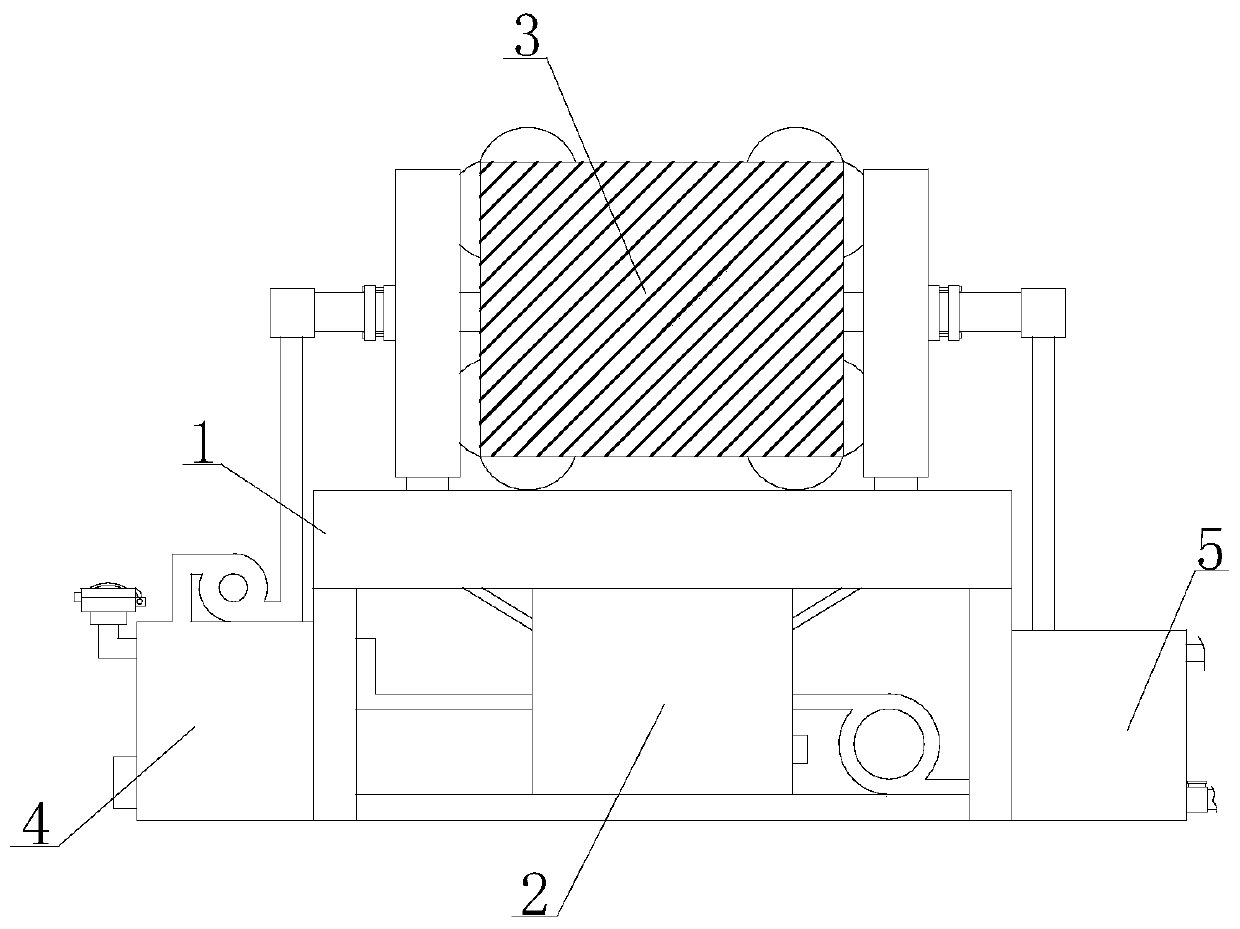

Automatic washing device for aluminum plate finned heat exchanger

A plate-fin heat exchanger and automatic cleaning technology, applied in the direction of cleaning heat transfer devices, flushing, lighting and heating equipment, etc., can solve problems such as low efficiency, inability to collect dirt in a centralized manner, environmental pollution, etc. Provides cleaning efficiency and quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

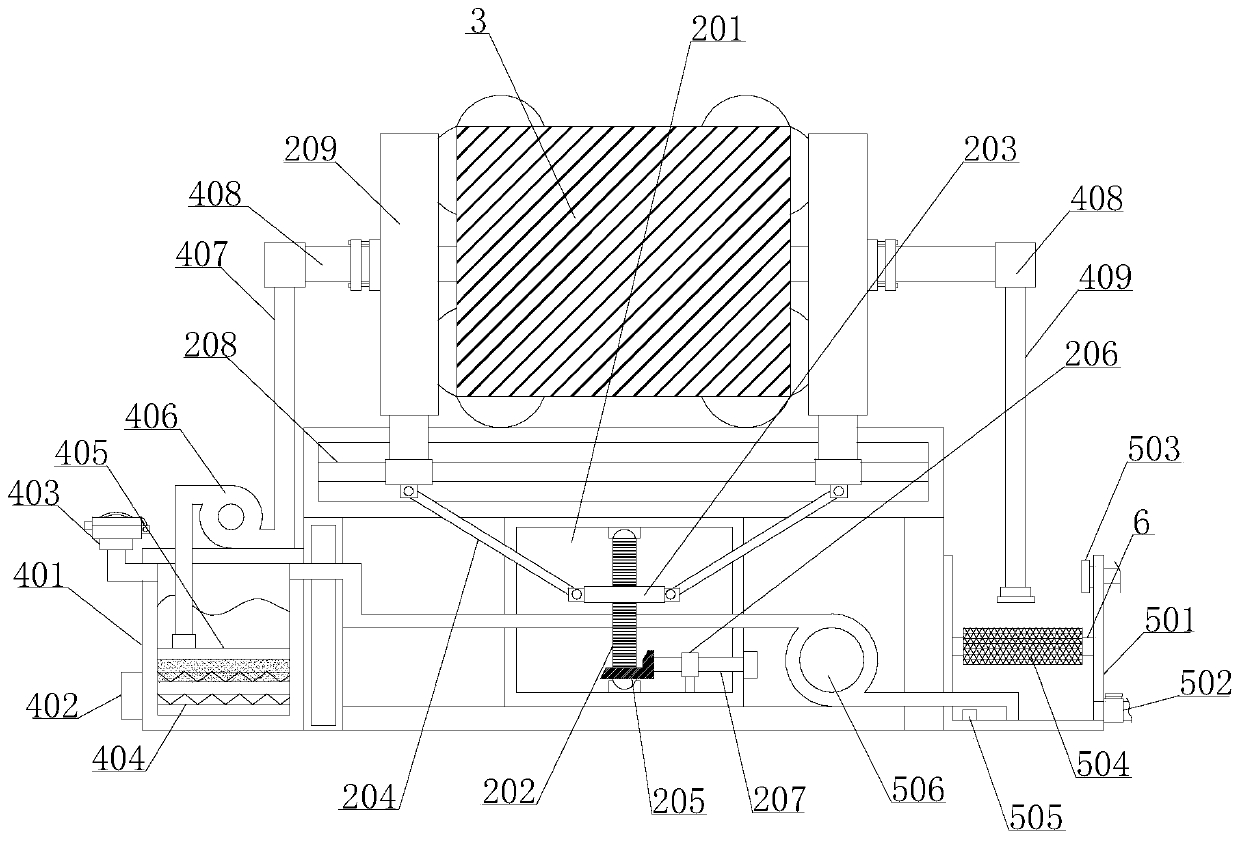

[0032]Embodiment 1, a temperature controller 402 is fixedly installed on the left side surface of the liquid storage tank 401, and a feeding port 403 is arranged on the top of the temperature controller 402, and an electric heating tube 404 is fixedly installed inside the liquid storage tank 401, and the top of the electric heating tube 404 A heat conduction plate 405 is provided, and the temperature of the heating pipe is adjusted by the temperature controller 402 to ensure that the temperature of the formic acid is at a level of 60 degrees. The raw material can be adjusted in the liquid storage tank 401 through the provided feeding port 403 to prepare formic acid.

Embodiment 2

[0033] Embodiment 2, a recovery box 501 is fixedly installed on the right side of the frame 1, and a drain pipe 502 is fixedly installed on the right side of the recovery box 501. The filter frame 504, the bottom surface of the recovery box 501 is fixedly equipped with a pH detector 505, and the interior of the frame 1 is fixedly installed with a return pump 506, and the mixture of formic acid and dirt discharged through the discharge pipe 409 is filtered through the filter frame 504, and the formic acid The solution enters the interior of the recovery box 501, and is checked by the pH detector 505. If the pH is less than 2, it can be reused. If it is greater than 2, it needs to be neutralized by adding water and then discharged.

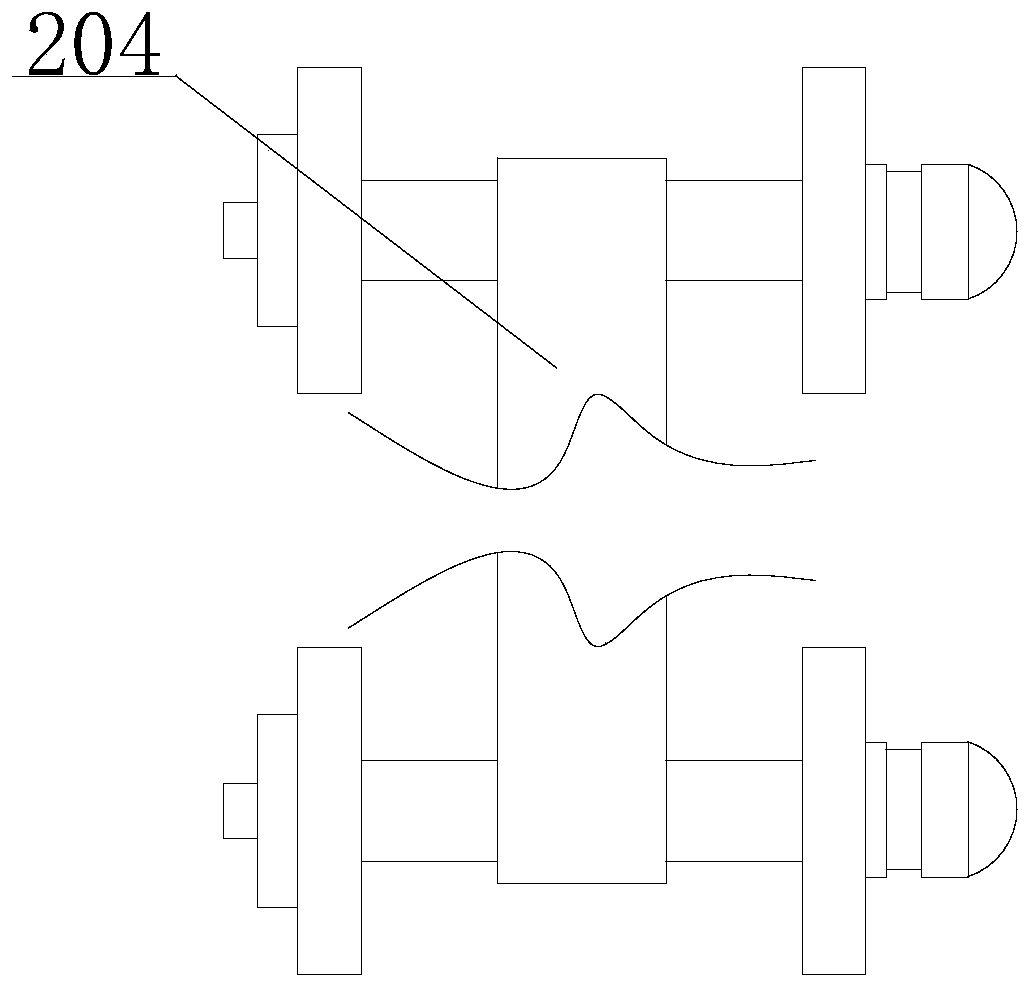

[0034] Working principle: Turn the rotating rod 207 to drive the adjusting screw 202 to rotate. At this time, the movable splint 209 is driven by the moving block 203 to clamp the heat exchanger body 3 firmly, and then the medium inlet and outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com