Melting device for fly ash solidification

A melting device and fly ash solidification technology, which is applied in the field of fly ash treatment, can solve the problems of high melting temperature, poor melting and solidification effect, and can not meet the needs of use well, and achieve the effect of uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as Figure 1-2 As shown, in the embodiment provided by the present invention, a melting device for fly ash solidification includes a shell 1, the side wall of the shell 1 has an interlayer 2, and the inner spiral of the interlayer 2 is provided with a spiral heat sink. The oil delivery pipe 3, the bottom of the housing 1 has a hot oil inlet pipe 4 communicating with the feed port at the bottom end of the spiral hot oil delivery pipe 3, the hot oil inlet pipe 4 is provided with a first control valve 5, The other side of the top of the housing 1 has a hot oil outlet 13 communicating with the interlayer 2;

[0030] Further, in the embodiment provided by the present invention, the inner cavity of the housing 1 is fixedly installed with an inner cylinder 14, and the outer wall of the inner cylinder 14 has an electromagnetic heater 15;

[0031] A stirring mechanism is provided along the central axis in the inner cylinder 14, and a stirring motor 17 for driving the stirr...

Embodiment 2

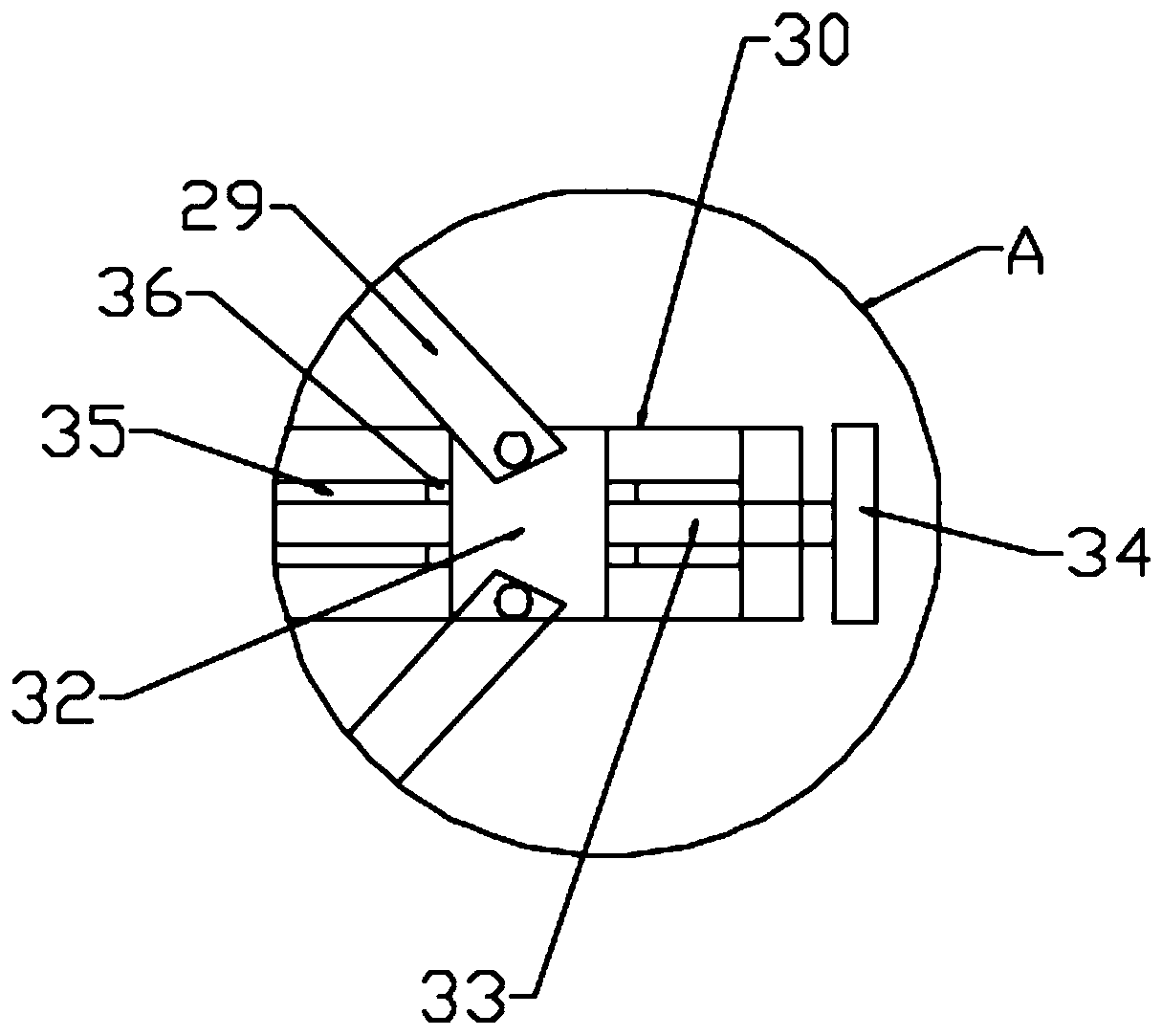

[0040] Such as figure 1 with Figure 4 As shown, the difference from Embodiment 1 is that in the embodiment provided by the present invention, the rotating cloth assembly also includes a support cylinder 22 coaxially fixed on the rotating disk 16, and the inner ring of the support cylinder 22 is fixed A driven toothed disc 21 is provided, and a driving toothed disc 20 engaged with the driven toothed disc 21 is fixedly mounted on the stirring shaft 24 in the support cylinder 22. Therefore, when the stirring motor 17 drives the stirring shaft 24 to rotate At this time, under the mutual engagement between the driving toothed plate 20 and the driven toothed plate 21, the rotary plate 16 can be pushed to rotate, therefore, through the first feeding funnel 18 or the second feeding funnel 19, it is put into the top of the inner cylinder 14 When the material in the cavity enters the lower inner cavity of the inner cylinder body 14 through the material distribution hole 23, the effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com