A reciprocating plunger pump

A plunger pump, reciprocating technology, used in the field of reciprocating pumps, can solve the problems of inability to automatically reverse, low mechanical efficiency, easy wear and tear of moving parts, etc., to save space and parts, reduce noise and failure, and run smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

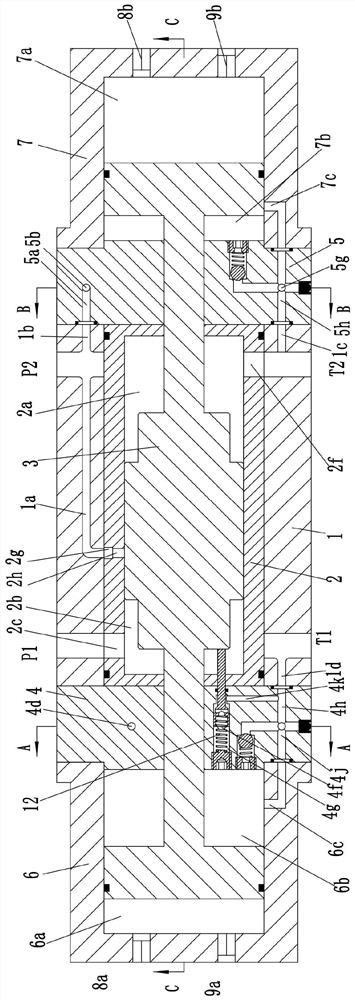

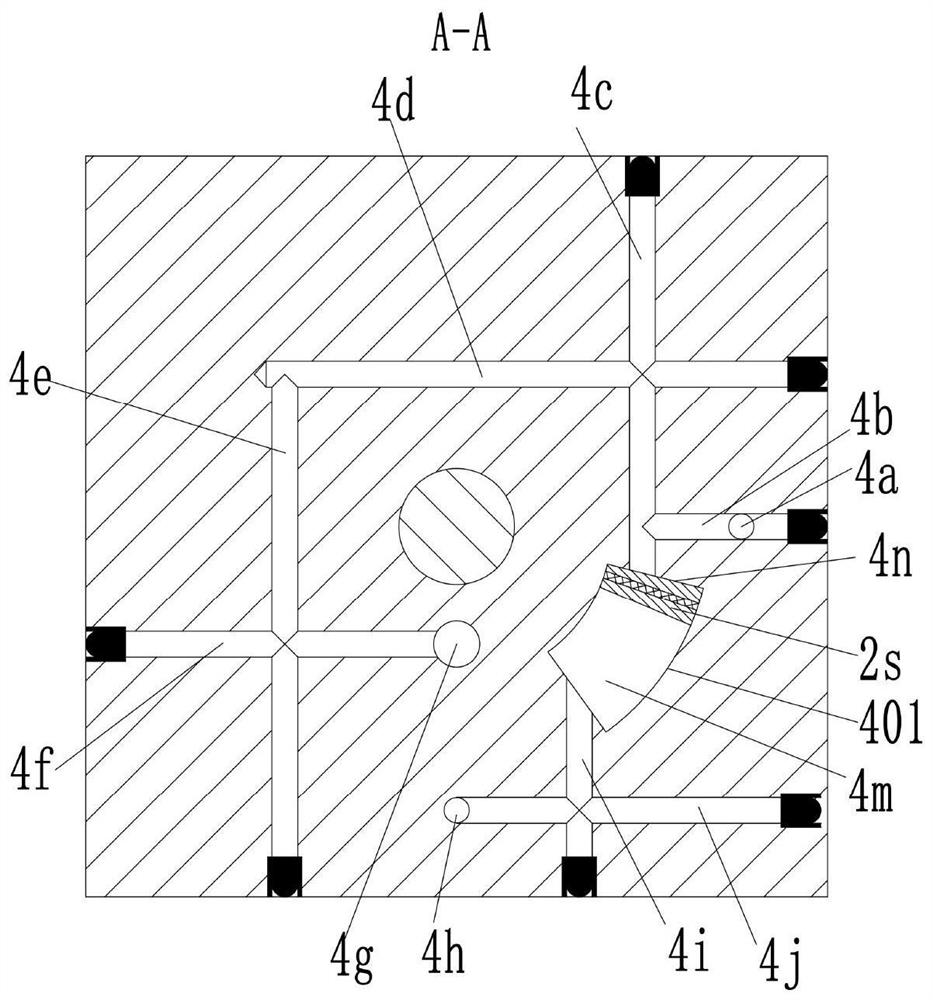

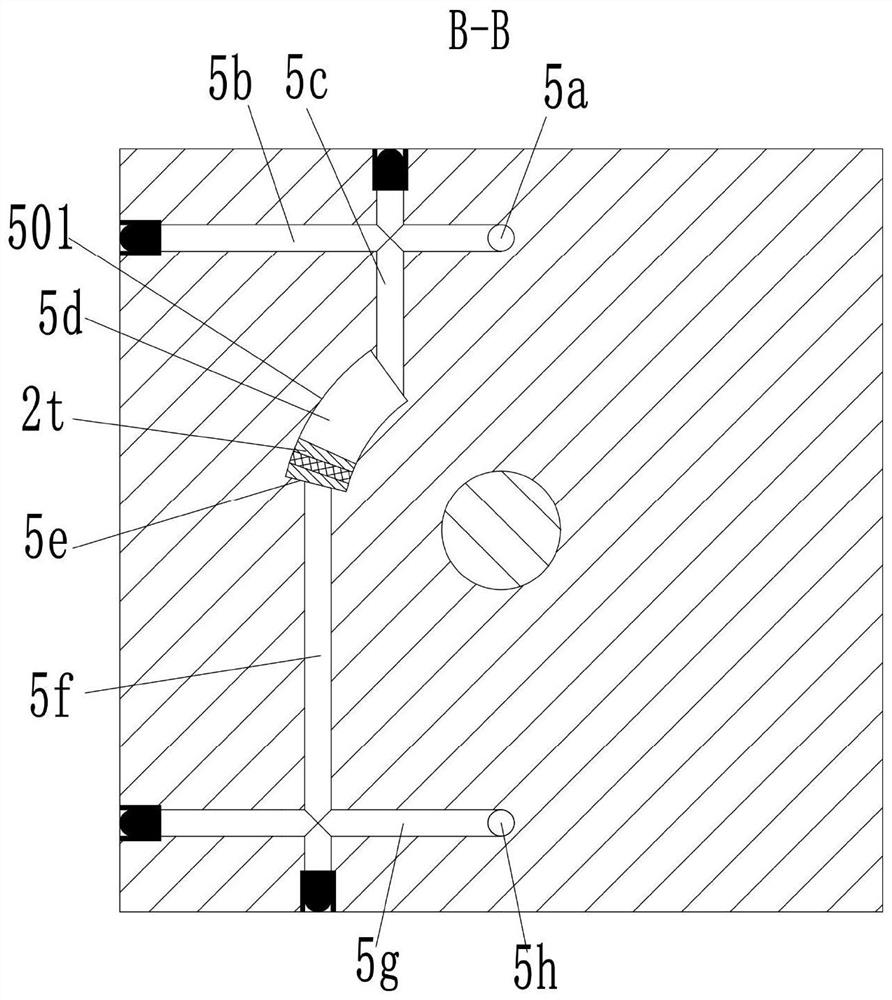

[0036] see Figure 1-16As shown, a reciprocating plunger pump includes a pump body 1, and the pump body 1 is provided with a left and right through installation hole 101; the left end of the pump body 1 is fixedly installed with a left end cover 4, and the right end is fixedly installed with a right end Cover 5; the left pump housing 6 is fixedly installed on the left side of the left end cover 4, and the right pump housing 7 is fixedly installed on the right side of the right end cover 5; the piston body 3 that moves left and right is provided in the installation hole 101, so The left end of the piston body 3 is provided with a left connecting rod 3a that passes through the left end cover 4 and extends into the left pump housing 6, and the right end is provided with a right connecting rod 3b that passes through the right end cover 5 and extends into the right pump housing 7. The left end of connecting rod 3a is provided with the left piston 3a1 that is slidably connected in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com