Hydrogen heat exchange medium monometal hydride acting system

A technology of heat exchange medium and hydride, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve problems affecting safe use, knocking, instability, etc., achieve economic benefits of energy saving and emission reduction, and create economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

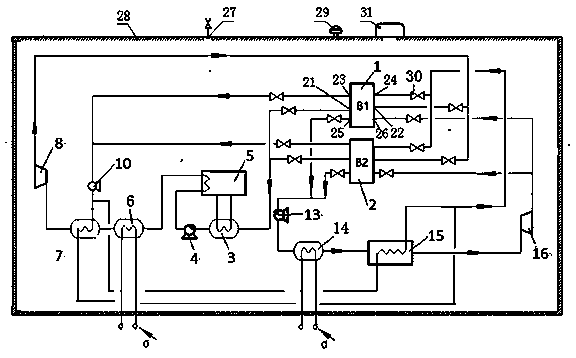

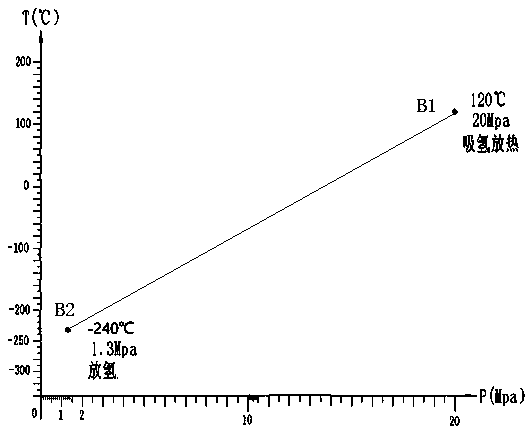

[0017] The hydrogen heat exchange medium single metal hydride work system of the present invention is as follows figure 1 As shown, it includes B1 metal hydrogen storage reaction bed 1, B2 metal hydrogen storage reaction bed 2, hydrogen liquefier 3, A air heat exchanger 6, A hydrogen heat exchanger 7, liquid hydrogen high pressure pump 4, high pressure hydrogen circulation pump 10 , B air heat exchanger 14, liquid nitrogen high pressure pump 13, nitrogen expander 16, B hydrogen heat exchanger 15 and refrigeration unit 5. The B1 metal hydrogen storage reaction bed 1 and the B2 metal hydrogen storage reaction bed 2 are respectively provided with a hydrogen absorption inlet 22 , a hydrogen discharge outlet 21 , a heat exchange inlet 24 , a heat exchange outlet 23 , a liquid nitrogen outlet 25 and a nitrogen gas inlet 26 . The hydrogen discharge outlet 21 of B1 metal hydrogen storage reaction bed 1 and B2 metal hydrogen storage reaction bed 2 is connected to the liquid hydrogen hi...

Embodiment 2

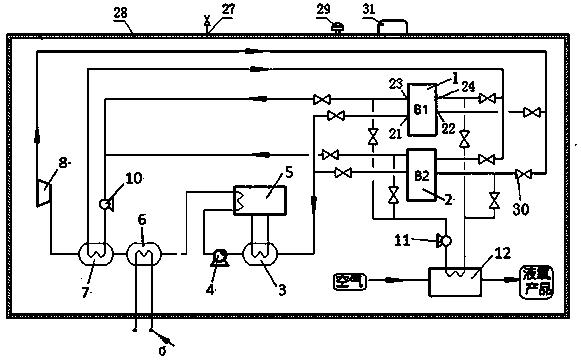

[0024] Another embodiment of the present invention is as figure 2 As shown, it includes B1 metal hydrogen storage reaction bed 1, B2 metal hydrogen storage reaction bed 2, hydrogen liquefier 3, A air heat exchanger 6, A hydrogen heat exchanger 7, hydrogen expander 8, liquid hydrogen high pressure pump 4, A high-pressure hydrogen circulation pump 10 , a low-pressure hydrogen circulation pump 11 , a liquid oxygen production unit 12 and a refrigeration unit 5 . The B1 metal hydrogen storage reaction bed 1 and the B2 metal hydrogen storage reaction bed 2 are respectively provided with a hydrogen absorption inlet 22 , a hydrogen discharge outlet 21 , a heat exchange inlet 24 and a heat exchange outlet 23 . The hydrogen discharge outlet 21 of B1 metal hydrogen storage reaction bed 1 and B2 metal hydrogen storage reaction bed 2 is connected to the liquid hydrogen high-pressure pump 4 through the hydrogen liquefier 3 through the high-pressure hydrogen pipeline, and the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com