Device for shield plane sliding stepping in narrow space and construction method thereof

A technology of shield tunneling and space, which is applied in the field of shield tunneling planar sliding stepping square devices in narrow spaces, which can solve the problems that shield tunneling cannot pass through on schedule, construction site is limited, and construction is difficult, so as to overcome construction difficulties, improve work efficiency, reduce Effects of Construction Safety Risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

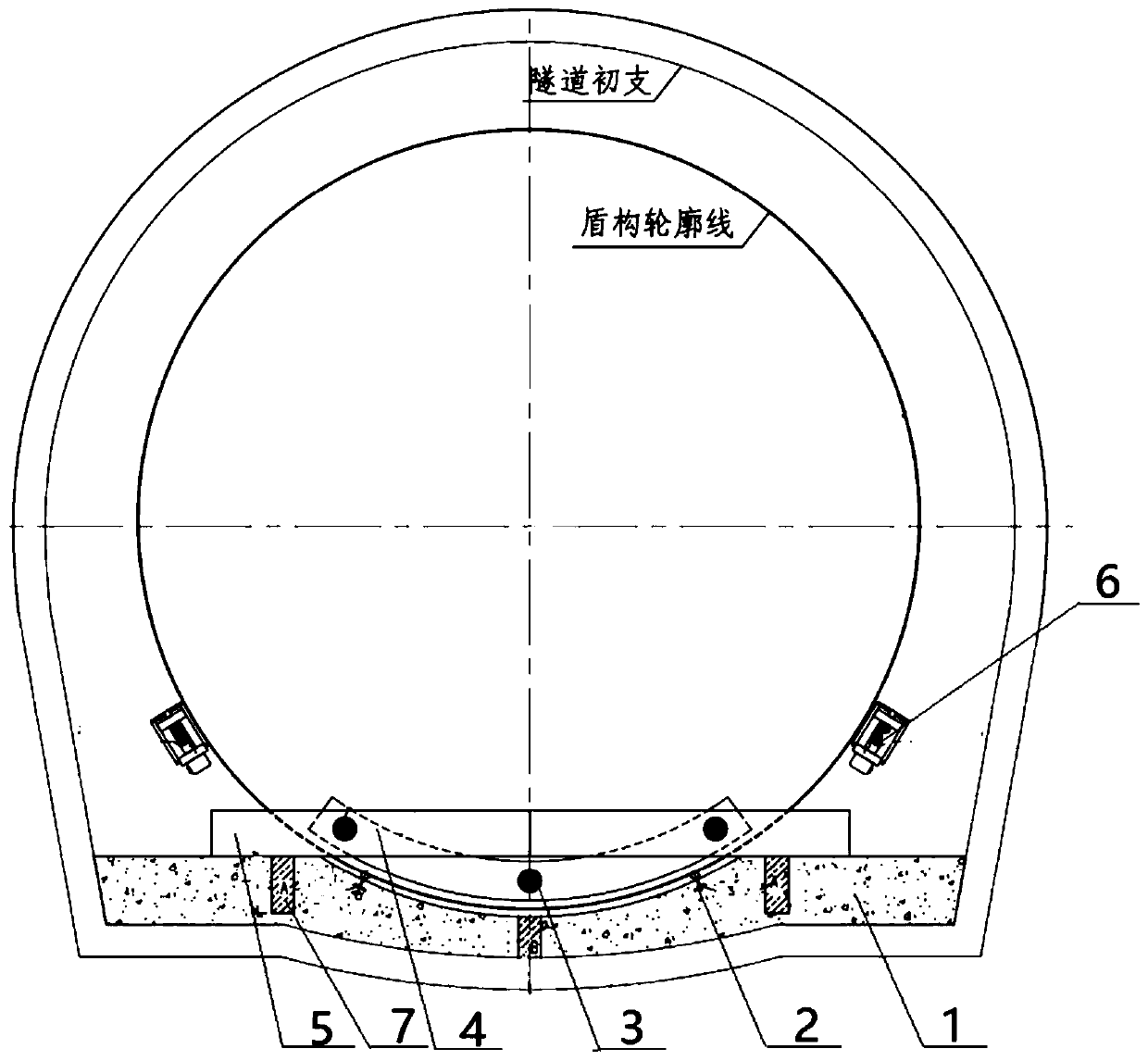

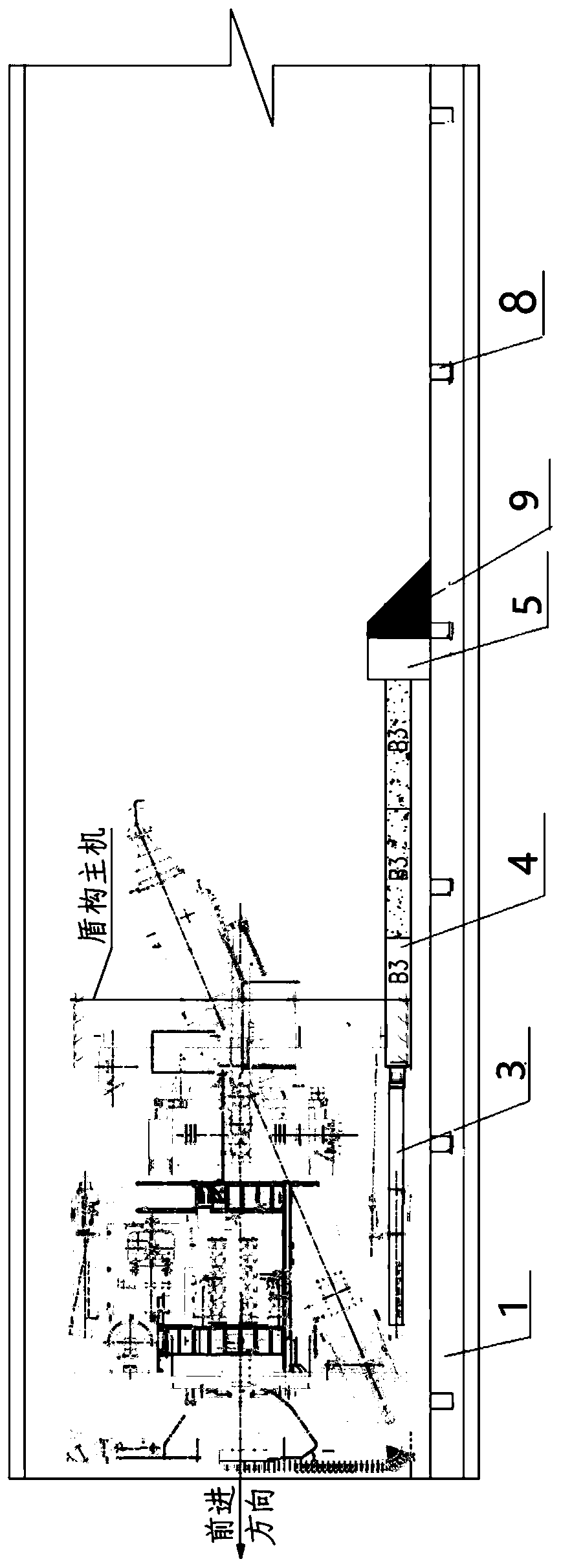

[0023] Such as figure 1 , figure 2 As shown, a device for sliding and stepping shield tunneling in a narrow space, including an arc-shaped guide platform 1 located at the bottom of the tunnel, and a guide rail 2 located on an arc-shaped high platform 1 to allow the main machine of the shield machine to pass through. The arc-shaped guide platform 1 adopts The reinforced concrete molded arc-shaped guide platform that has been constructed is used as the support of the shield main machine and the sliding platform; it also includes a force transmission mechanism connected to the propulsion cylinder 3 on the shield main machine and a force transmission mechanism located on the shield main machine for pulling force transmission. Auxiliary force transmission mechanism of the mechanism, the force transmission mechanism includes several force transmission blocks 4 connected with one end of the propulsion cylinder 3, a crossbeam 5 connected with the force transmission block 4, a reactio...

Embodiment 2

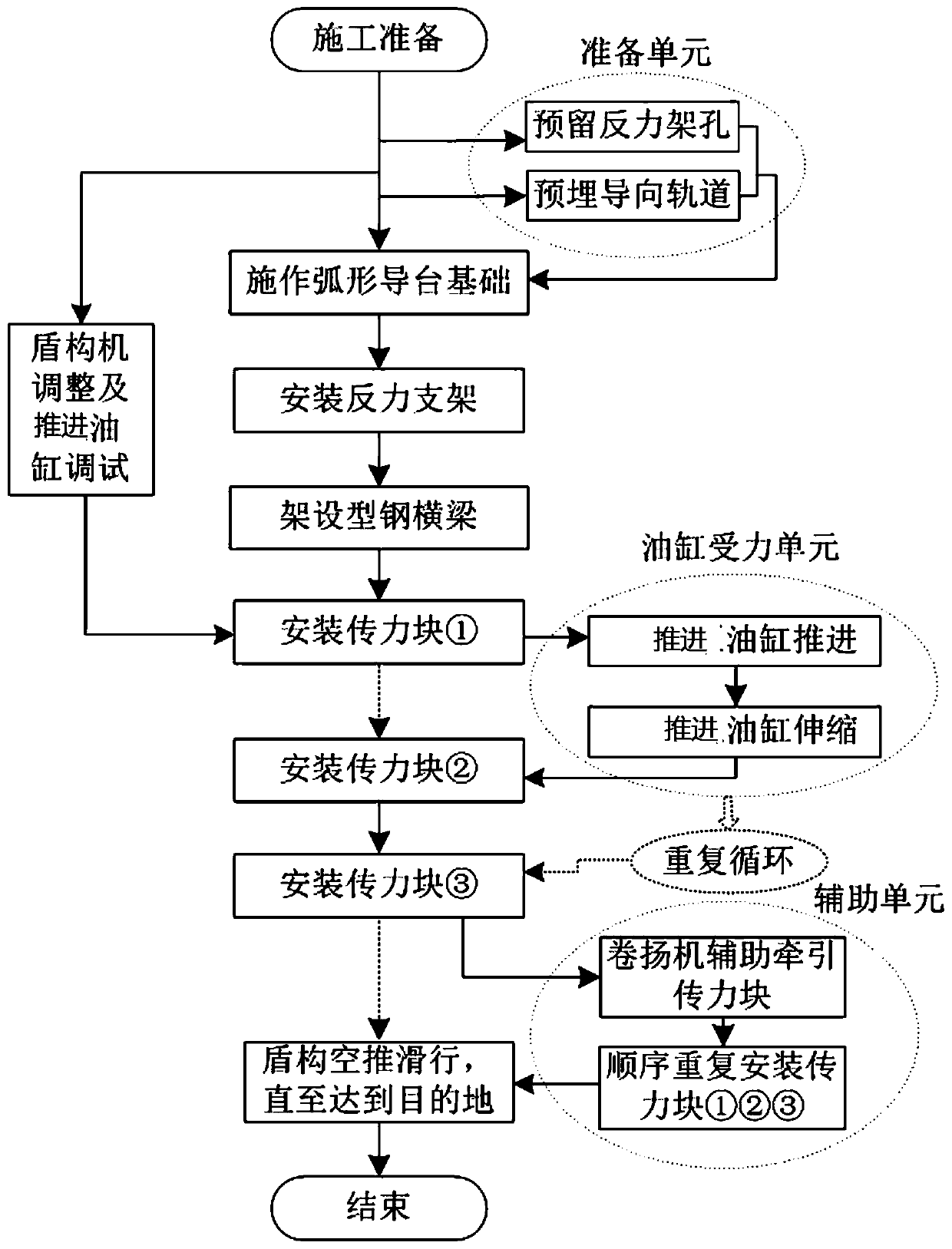

[0028] A construction method for a device for shield tunneling in a narrow space as in Example 1, comprising the following steps: (1) construction preparation, the construction preparation mainly includes constructing an arc-shaped guide platform foundation, and A hole 8 is reserved on the guide platform, and the guide rail 2 for the passage of the main shield machine is pre-embedded, and then the position of the main shield machine and the propulsion cylinder 3 are adjusted; The supporting legs of the counterforce support 9 are located in the reserved holes 8, and then the crossbeam 5 is installed on the right side of the support column 11 of the counterforce support 9, and a certain number of force transmission blocks 4 are installed on the other side of the crossbeam 5, and the force transmission blocks 4 and beam 5 are connected by bolts, and the number of force transmission blocks 4 is determined according to the advancing distance of the shield machine. Two adjacent force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com