A method of extreme cluster perforation fracturing for long horizontal wells in tight reservoirs

A technology for long horizontal wells and tight reservoirs, which is applied in the fields of earth-moving drilling, wellbore/well components, and production fluids, etc., which can solve the problem that the output of a single well cannot meet expectations, the difference is large, the operation cost and construction period increase, etc. problem, to achieve the effect of balanced crack initiation, good and effective opening, and effective opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

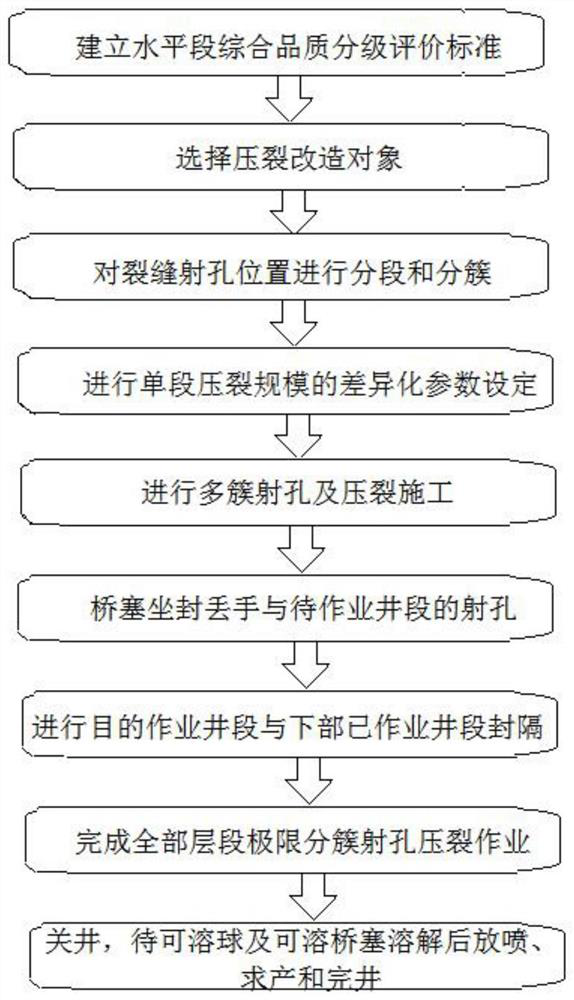

[0058] according to figure 1 A limit cluster perforation fracturing method for long horizontal wells in tight reservoirs shown, including the following steps

[0059] Step 1: Establish comprehensive quality grading and evaluation standards for horizontal sections

[0060] According to the logging results of long horizontal wells in tight reservoirs, the numerical values in the identification factors of integrated geology-engineering integration sweet spots are screened, and the comprehensive quality grading and evaluation standards for horizontal sections are established. The established comprehensive quality grading and evaluation standards for horizontal sections are divided into I, II, and III kind;

[0061] Step 2: Select the object of fracturing stimulation

[0062] According to the comprehensive quality classification result of the horizontal section in step 1, the horizontal section of category I and II is selected as the object of fracturing;

[0063] Step 3: Segm...

Embodiment 2

[0078] according to figure 1 The difference between the extreme clustered perforation and fracturing method for long horizontal wells in tight reservoirs shown in the first embodiment is that the integrated geology-engineering integration sweet spot identification factors screened in the first step include physical property indicators, Oily index, in-situ stress index and brittleness index; the physical property index adopts effective porosity, the oily index adopts oil saturation, the in-situ stress index adopts the minimum horizontal well principal stress, and the brittleness index adopts brittleness index.

[0079] Preferably, the comprehensive quality of the horizontal section established in the step 1 is divided into I, II, and III classes, and the specific grading evaluation criteria are as follows:

[0080] (1) Type I sweet spots: effective porosity ≥ 5%, oil content ≥ 70%, minimum horizontal well principal stress ≤ 30MPa, brittleness index ≥ 50%.

[0081] (2) Class II...

Embodiment 3

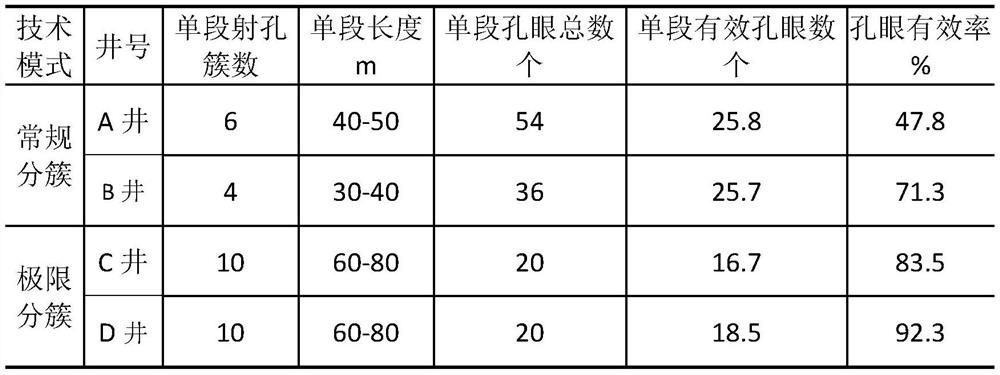

[0093] according to figure 1 The shown limit cluster perforation fracturing method for long horizontal wells in tight reservoirs is different from the first embodiment in that: when performing segmentation and clustering in the second step, the cluster spacing is 5-10m, The number of perforation holes in a single cluster is 2 holes / cluster, the number of fracture clusters in a single section is 8-12 clusters / section, and the length of a single section is 60-80m.

[0094] In actual use, the fracture perforation position is selected according to the reservoir logging interpretation results, and the cluster spacing is 5-10m, which greatly reduces the number of perforation holes in a single cluster, from the conventional 9-12 holes / cluster to 2 holes / cluster, and Significantly increase the number of fracture clusters in a single section, from 4-6 clusters / section to 8-12 clusters / section, and increase the length of a single section from 30-50m to 60-80m.

[0095] The technical sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com