Intermittent oil recovery control method

A control method and intermittent period technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve problems such as low production, oil pump emptying or insufficient fullness, and shortened service life of oil production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing.

[0022] A control method for intermittent oil recovery, comprising the following steps:

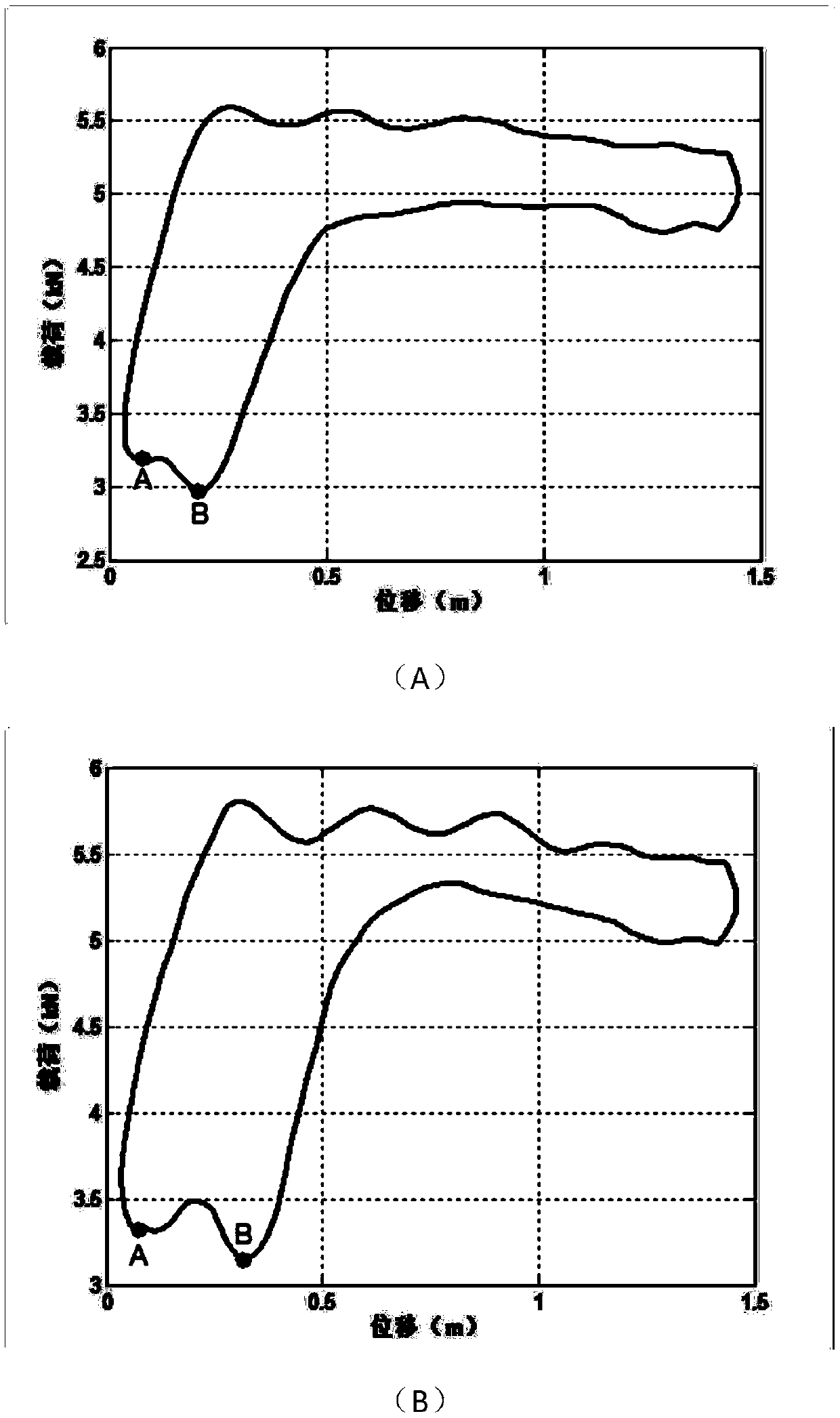

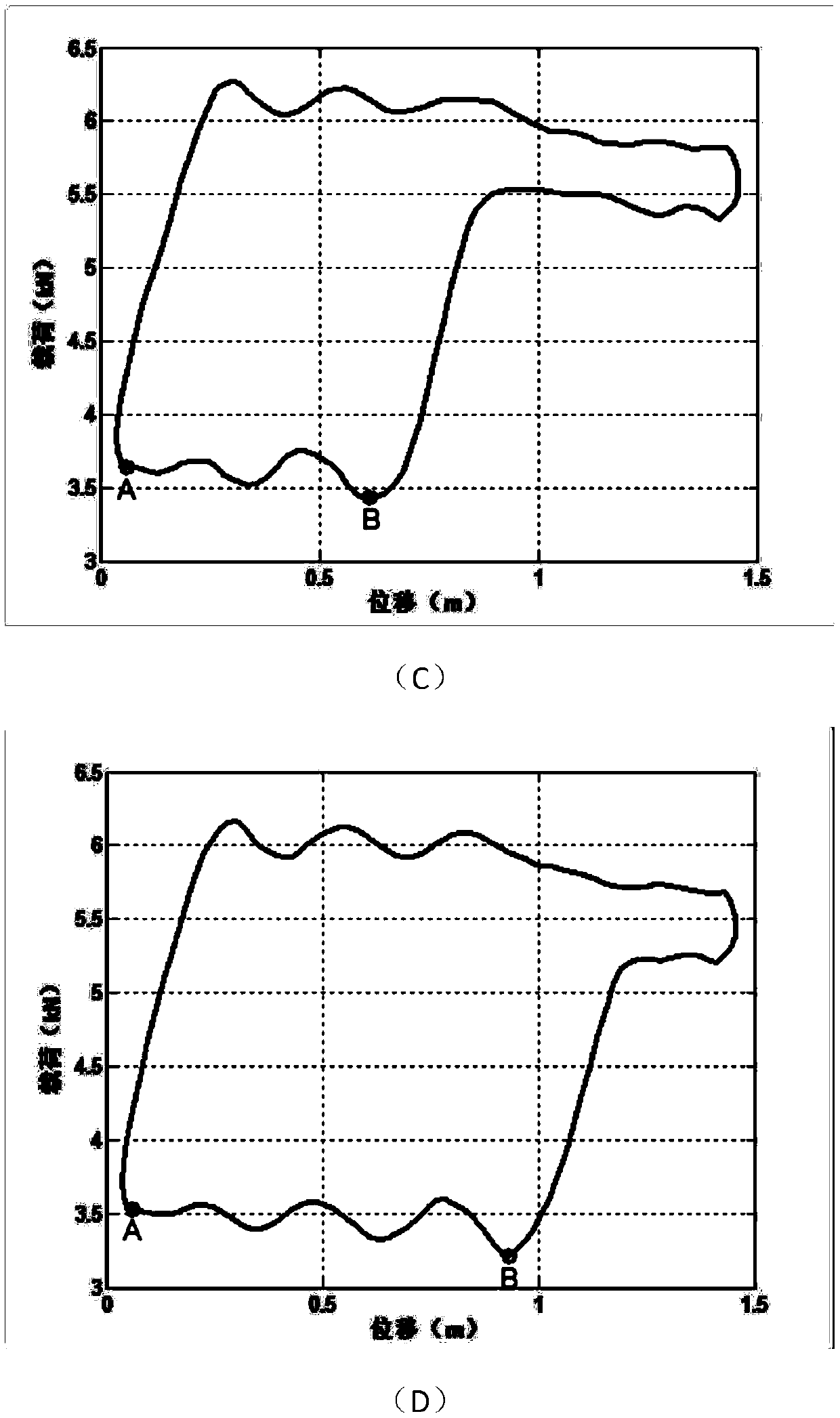

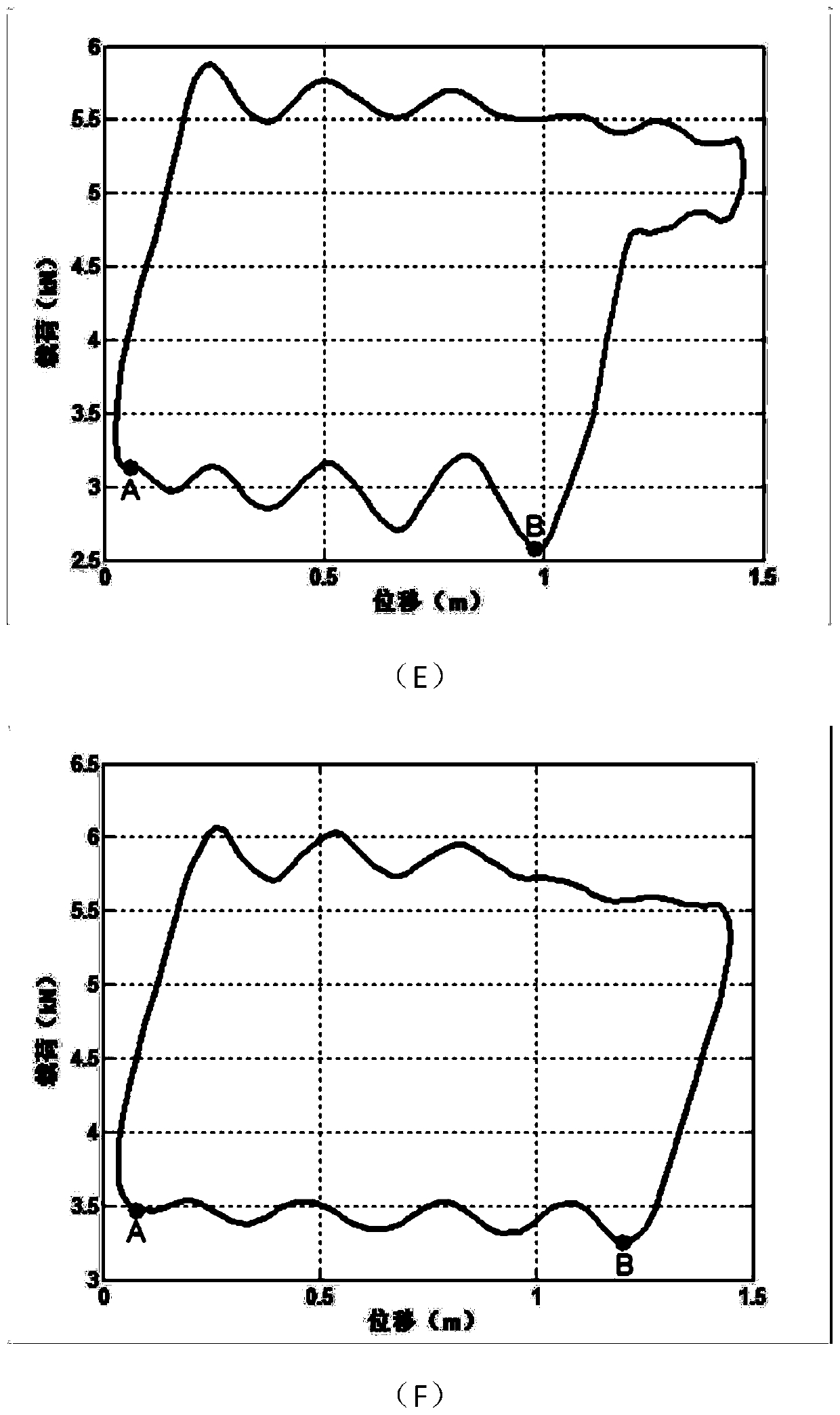

[0023] Step 1: Collect the dynamometer diagram. When the effective stroke of the dynamometer diagram is less than 10% of the plunger stroke, stop and resume, and the shutdown resumes as an intermittent period. During the intermittent period, start to collect the oil well dynamometer diagram every 0.5 hours, 1 hour or 2 hours And record the collection time, and then shut down to get the change law of the effective stroke of the dynamometer diagram in the intermittent period over time, such as figure 1 Shown: During the intermittent period, stop and recover, start up every 0.5 hours to collect the oil well dynamometer diagram, and then shut down, to obtain the change law of the effective travel of the dynamometer diagram during the intermittent period with time.

[0024] Step 2: When the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com