Method for increasing yield of corn starch

A technology of corn starch and corn kernels, applied in the biological field, can solve the problems of difficult separation of starch and protein, negative environmental impact, shortening of soaking time, etc., and achieve the effects of saving industrial procedures, maintaining enzyme activity, and reducing soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for improving cornstarch yield, comprising the steps of:

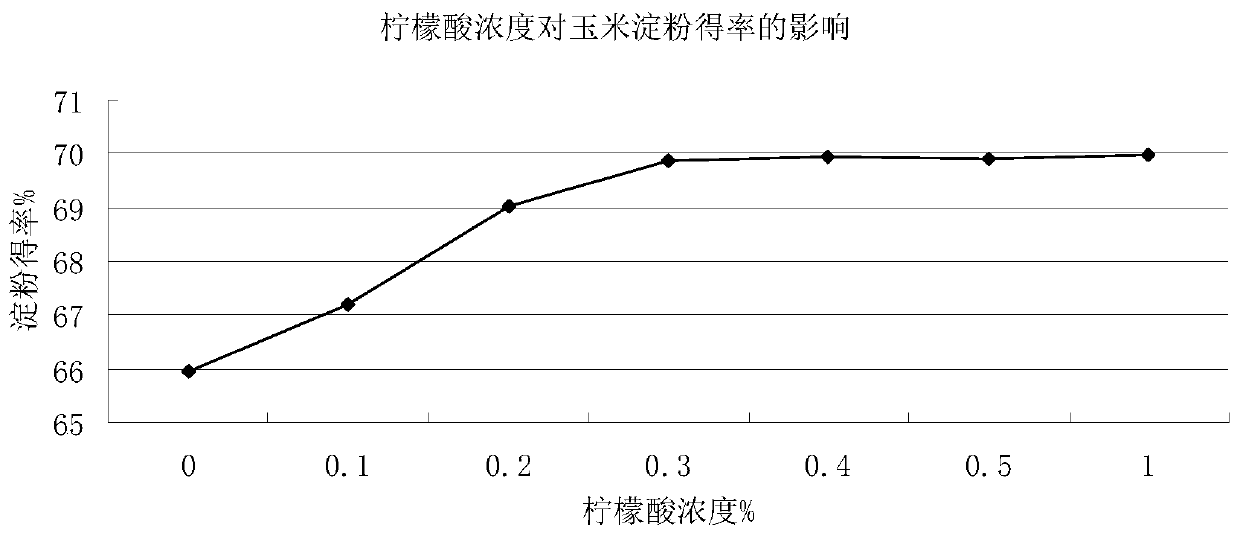

[0033] Put the corn kernels into the soaking tank, then add 0.3% (w / v) citric acid aqueous solution to the soaking tank, the addition amount is: corn kernels: citric acid aqueous solution = 1kg: 1.5L, soak for 8h, then microwave for 4min, The microwave power is 300W, stop the microwave, then add acid protease (20000U / g), the addition amount is 200U / L, and enzymatically hydrolyze at 45°C for 6h. Corn starch is obtained by crushing and separating the germ, refining, sieving, centrifuging, washing, dehydrating and drying.

[0034] Specifically, cornstarch can be prepared by referring to the conventional process:

[0035] Crush and separate the germ:

[0036] The purpose of coarse crushing is mainly to break the soaked corn into small pieces of more than 10 pieces in order to separate the germ.

[0037] Grinding and sieving:

[0038] The mixture of corn fragments and part of the starch after separation ...

Embodiment 2

[0044] A method for improving cornstarch yield, comprising the steps of:

[0045] Put the corn kernels into the soaking tank, then add 0.25% (w / v) citric acid aqueous solution to the soaking tank, the addition amount is: corn kernels: citric acid aqueous solution = 1kg: 2L, soak for 8h, then microwave for 6min, microwave The power is 300W, stop the microwave, then add acid protease (20000U / g), the addition amount is 300U / L, enzymolysis at 45°C for 4 hours; after crushing and separating germ, fine grinding, sieving, centrifugal separation, washing, dehydration and drying to obtain cornstarch.

Embodiment 3

[0056] The cornstarch yield comparison of embodiment 1-2, comparative example 1-3.

[0057] The calculation method of corn starch yield refers to the conventional method, specifically, the following method can be referred to:

[0058] D=(X 2 / X 1 )×100%

[0059] In the formula, D is the yield of corn starch; X 2 is the quality of cornstarch; X 1 dry weight of corn.

[0060] The starch content in the corn grains of the present invention is 72.1%, and the starch processing procedures of each group are completely the same and comparable; the specific results are shown in Table 1:

[0061] Table 1

[0062] group Corn starch yield % Example 1 69.86 Example 2 69.71 Comparative example 1 65.49 Comparative example 2 61.32 Comparative example 3 67.15

[0063] Through the comparison of each comparative example, it is found that the yield of cornstarch in the present invention is the highest, which can reach 69.86%, which is significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com