Cable error code eliminating method, system and device

A technology for clearing device and wrong code, which is applied in the direction of cable/conductor manufacturing, circuit, electrical components, etc., can solve the problems of poor clearing effect, low efficiency of wrong code clearing, and high labor cost, so as to save ink thinner and improve clearing effect, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

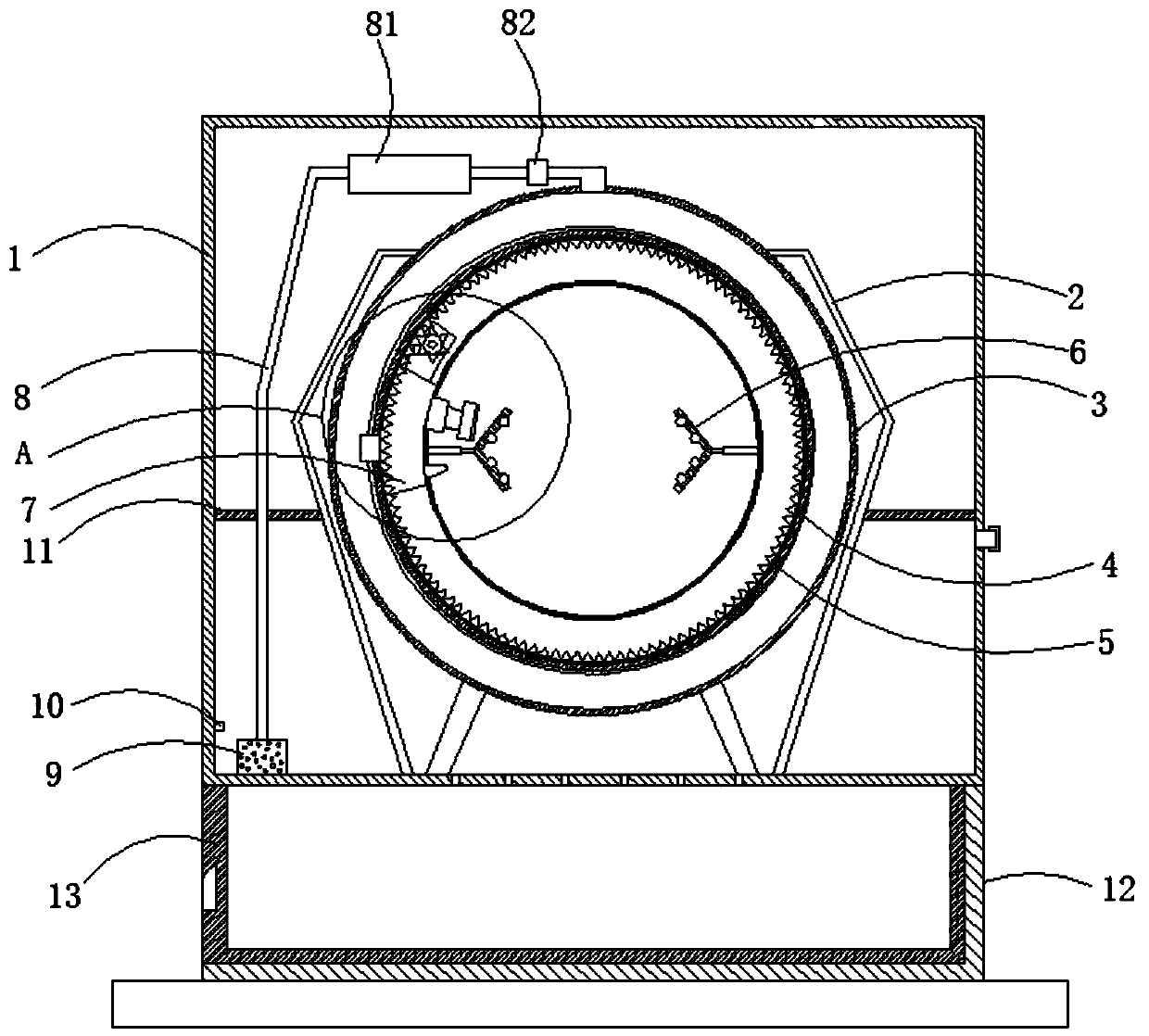

[0033] A cable error code removal method, comprising the following steps:

[0034] Step 1: Identify the surface of the pre-scanner cable, determine that a certain section of the cable has an ink mark, and initially determine the position of the ink mark, that is, perform fuzzy positioning;

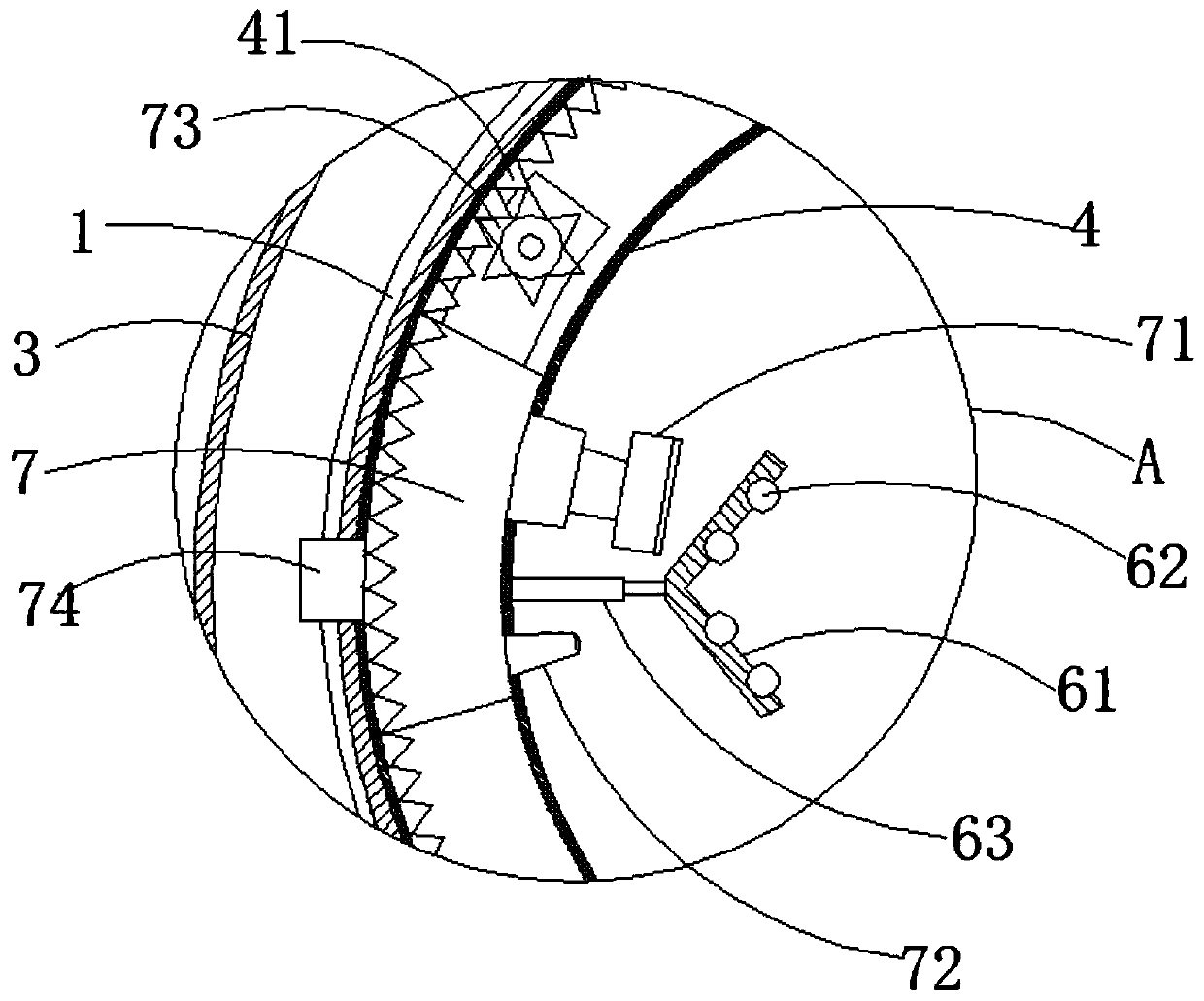

[0035] Step 2: Further identify the surface of the cable by the main scanner, accurately determine the position of the ink mark on the cable, and at the same time, the controller controls to stop the unwinding and rewinding of the cable;

[0036] Step 3: After the precise positioning is completed, according to the scanning result of the main scanner, the controller controls the nozzle to perform precise high-pressure spraying according to the position of the ink mark on the cable line, and cleans the ink mark on the cable;

[0037] Step 4: The cleaned cables are wiped by the wiping structure, and then rolled up.

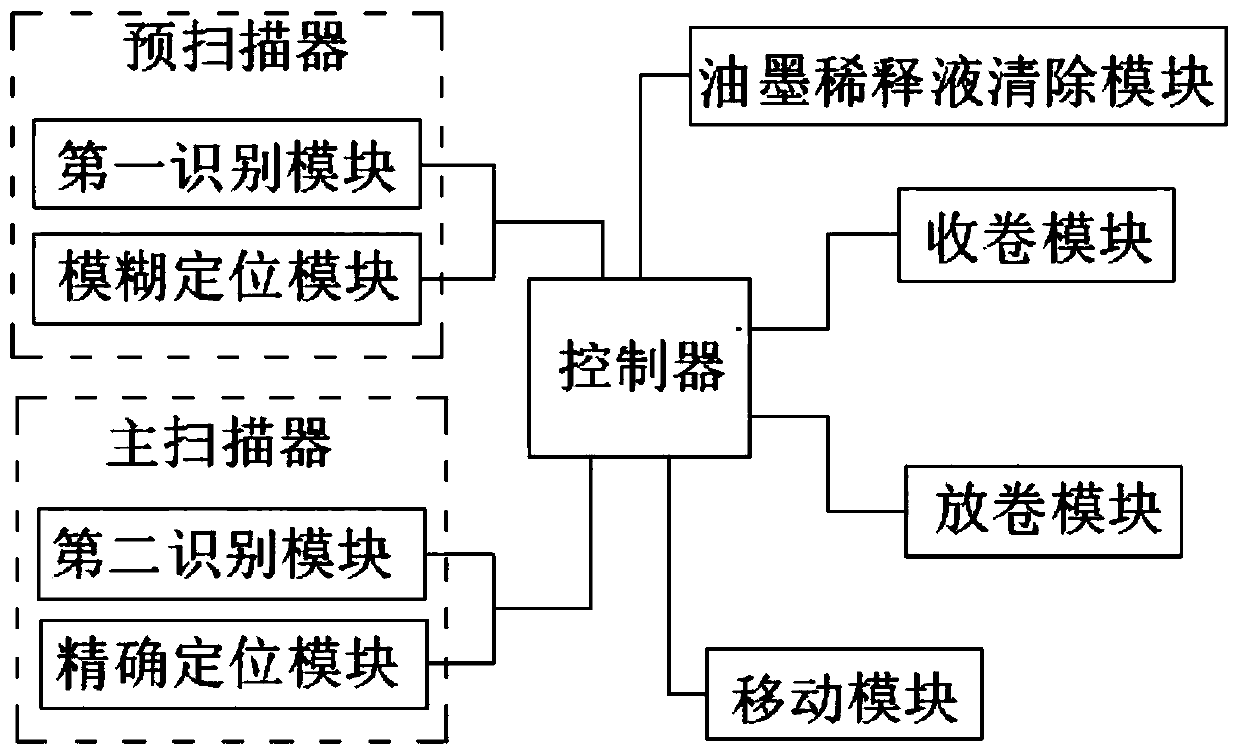

[0038] A cable error code removal system based on the above cable error cod...

Embodiment 2

[0052] Further, different from Embodiment 1, the main box 1 outlet side in this embodiment is also provided with a wiping structure 18, and the wiping structure 18 includes a fixing piece 181, a fixing screw 182, an upper wiping body 183 and a lower wiping body 184, so The lower end of the fixing piece 181 is fixedly connected to the outer support 16, and the upper end of the fixing piece 181 is provided with an adjustable upper wiping body 183 and a fixed lower wiping body 184. By unscrewing the fixing screw 182, the upper wiping body 183 can be adjusted. The position is convenient for wiping cables of different diameters; the opposite sides of the upper wiping body 183 and the lower wiping body 184 are provided with a wiping sponge 1831 and a wiping cloth 1832 wrapping the wiping sponge 1831 for wiping residual ink on the cable Imprint, guaranteed to remove effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com