Method for manufacturing composite curtain

A manufacturing method and technology of composite cord fabrics, applied in the field of curtains, can solve the problems of pattern breakage, color, pattern monotony, and unsatisfactory aesthetic performance, and achieve the effect of increasing competitiveness and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

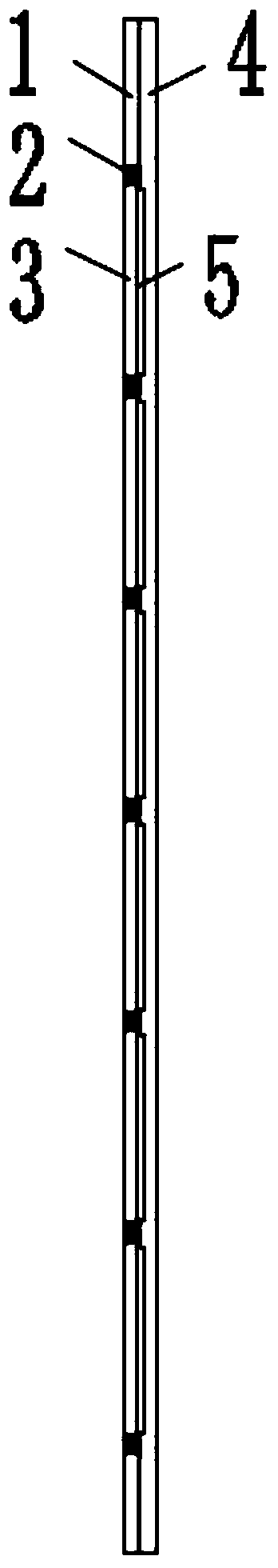

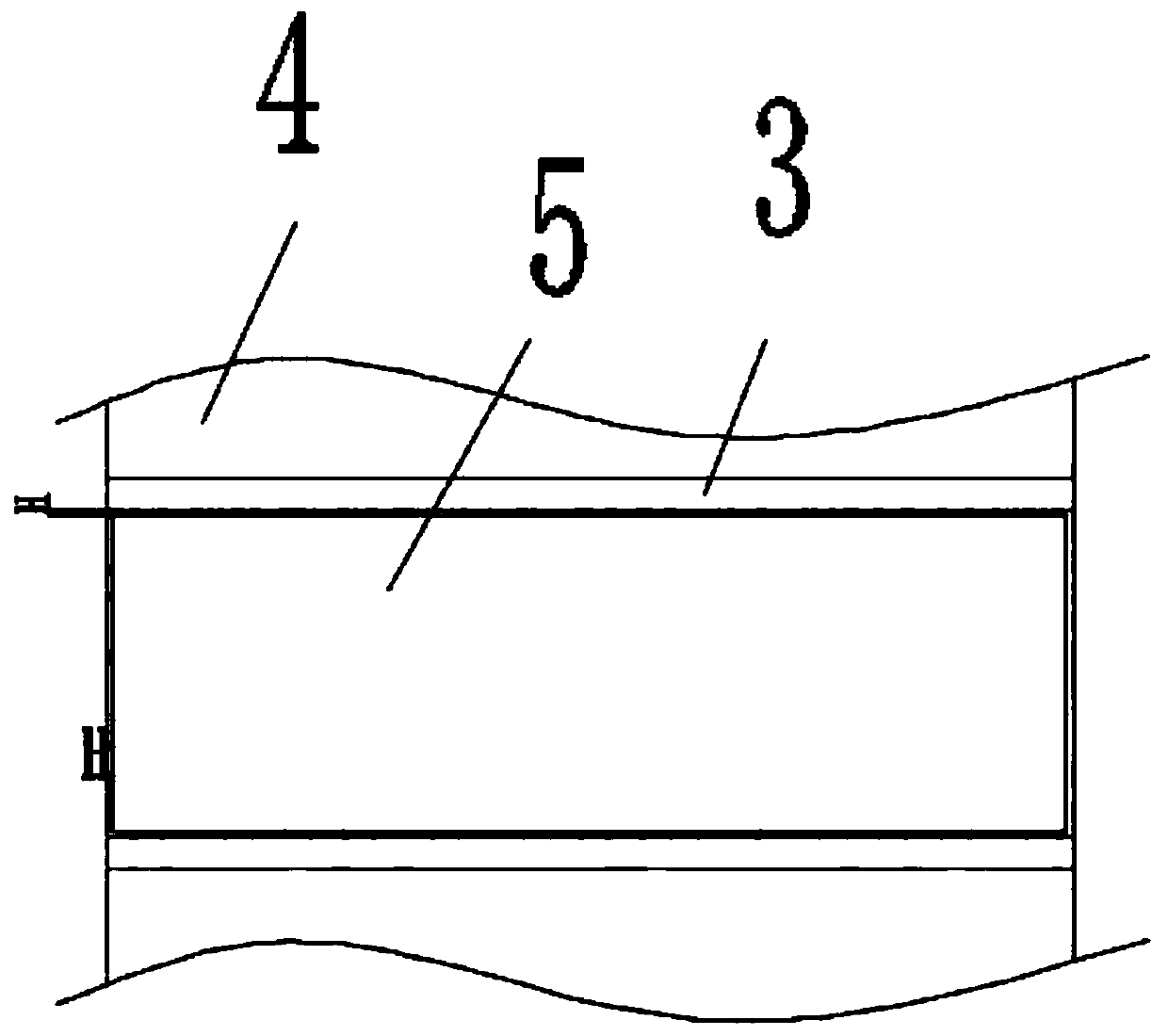

[0029] Embodiment 1: as Figure 1-2 And as shown in 8, the composite curtain includes a bottom composite cord 1, a slit 2 disposed on the bottom composite cord 1 and a bottom sub-ply 3 arranged on the bottom composite cord 1, because the above-mentioned structures are all prior art, Therefore, no more detailed narration here, the applicant found that the existing composite curtains are generally single-layer structures, which adopt a foldable method, but because they need to be folded, it is inevitable to divide the bottom composite curtain into two parts. A plurality of bottom surface sub-ply, which makes there is a gap between the two bottom surface sub-ply, which is easy to fold, and the existence of the gap makes the entire bottom composite ply is separated. Once the pattern is to be set on it, then Because of the existence of gaps, the pattern breaks, causing the overall style to be unattractive, affecting the look and feel, and also affecting the competitiveness of the p...

Embodiment 2

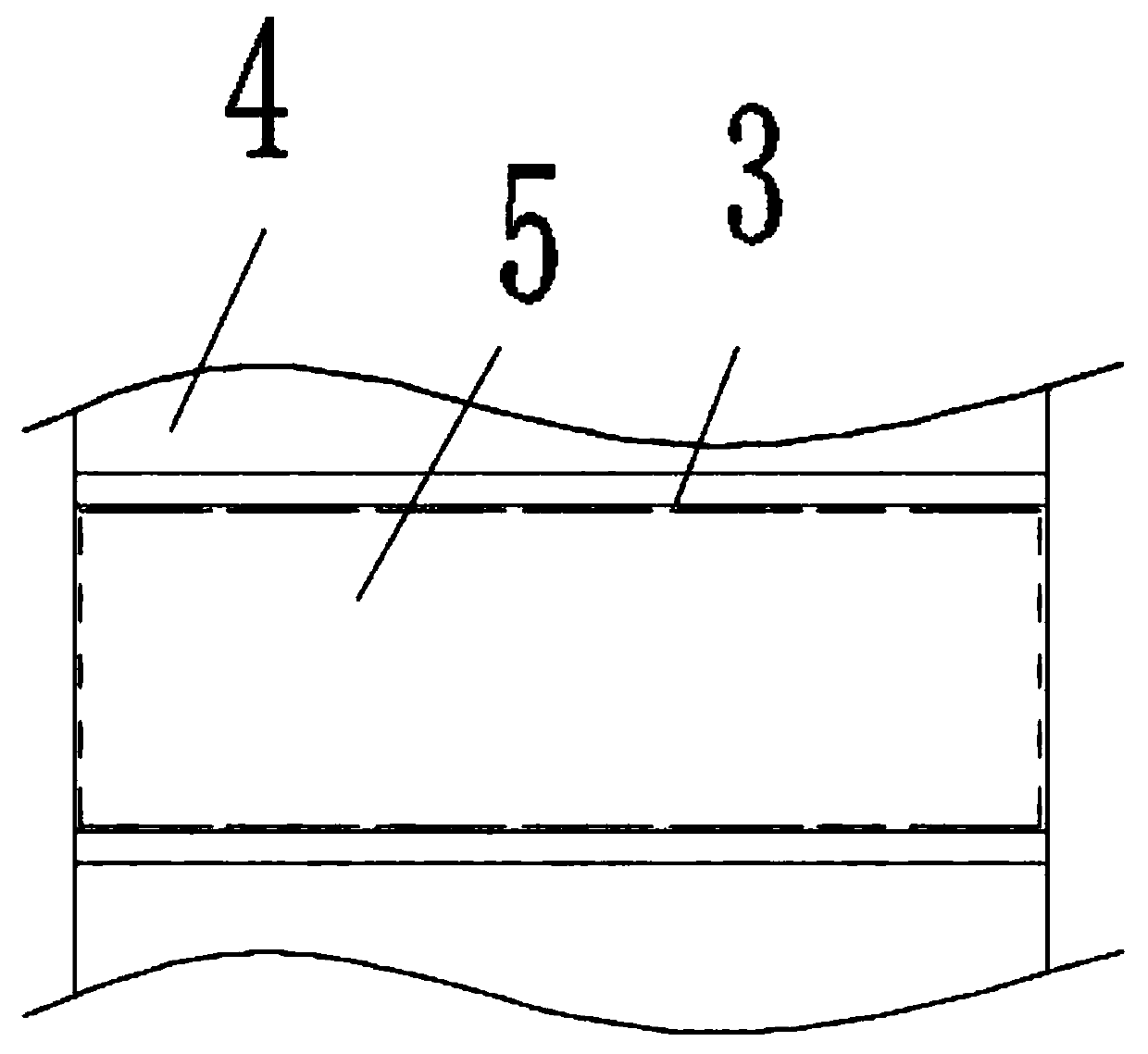

[0039] Embodiment 2, see attached Figure 6 , in this embodiment, the width of the surface composite cord is greater than the width of the bottom composite cord, and the two sides of the surface composite cord in the length direction are bent and extended to wrap the sides of the bottom sub-ply, also That is to say, the side surface in the longitudinal direction of the composite ply is bent and extended like the bottom surface of the bottom ply, and is wrapped by the fixing part, Figure 6 The middle fixing part fixes the curved part of the surface composite cord and the bottom surface of the bottom sub-ply, see Figure 7 , Figure 7 structure and Figure 6 The difference lies in the setting of the fixed part, in Figure 7 Among them, the fixing part is not only fixed to the surface of the bottom sub-ply, but also fixed to the bottom surface of the bottom sub-ply. All the other are with embodiment 1.

[0040] The manufacturing method of composite curtain is characterized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com