Composite airfoil-like sandwich structure and forming method thereof

A technology of sandwich structure and composite materials, which is applied to other household appliances, household appliances, household components, etc., to achieve the effects of improving strength and rigidity, ensuring compliance, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Forming a composite material wing "sandwich" weight-reducing structure includes the following steps:

[0059] ①Set the density to 110kg / m 3 The Degussa PMI foam is tested for compressive strength, and the compressive strength of the foam is required to be not less than 1.9MPa at 130°C, and it can be used only after passing the test.

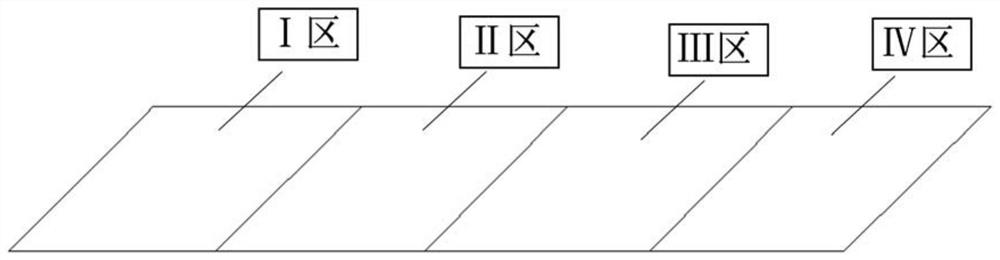

[0060] ②Machining the qualified foam figure 1 shape.

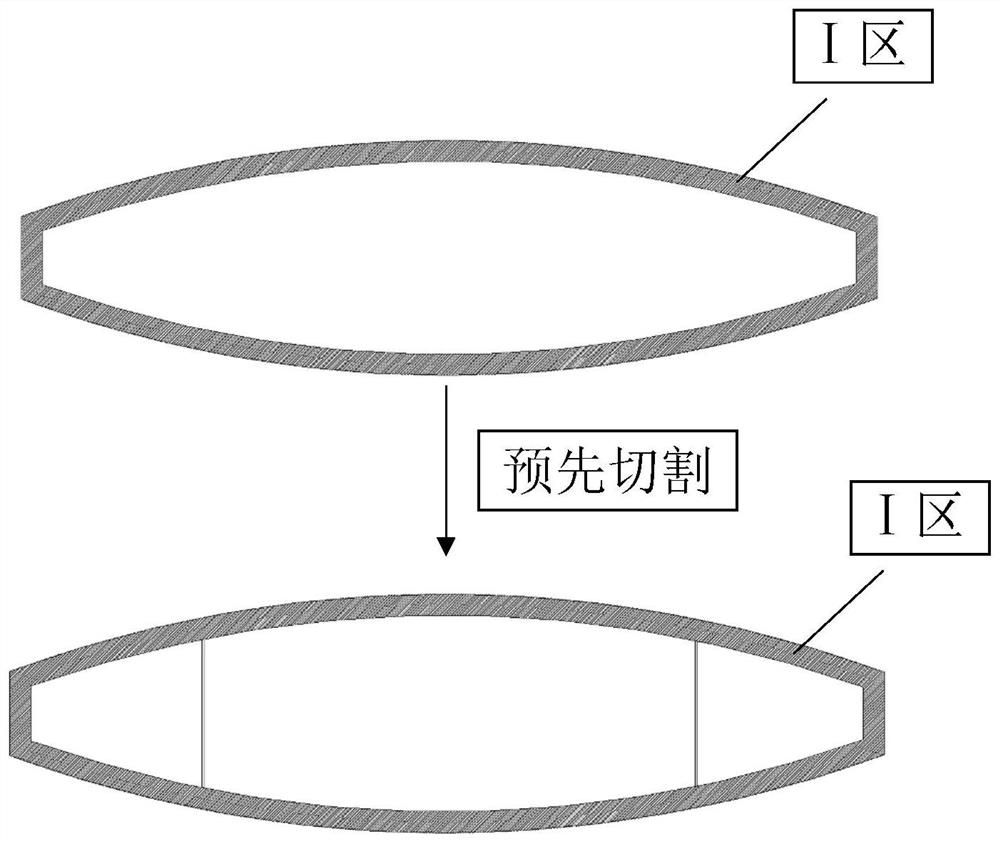

[0061] ③Put the foam in wing root zone Ⅰ according to figure 2 The shape of the foam is pre-cut into three pieces; after drying the machine-added foam in an oven at 130°C±5°C for 3 hours, use a hair dryer to clean the surface debris.

[0062] ④Apply a layer of J-47B glue evenly on the surface of the foam, let it dry for 20-30 minutes, and stick a layer of J-47A glue film.

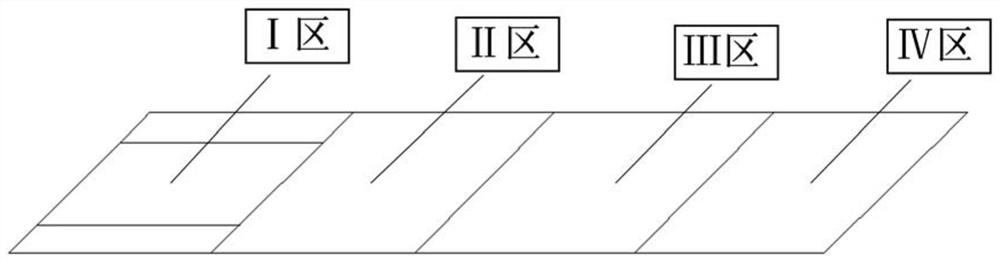

[0063] ⑤Wrap each of the three pieces of pre-cut foam in wing root area Ⅰ with 4 layers of carbon fiber prepreg (T700 / 9368 prepreg), lay up [90 / 90 / 0 / 90], and then combine the three pieces of foam with Ⅱ ~ The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com