Oval bamboo weaving mold

An elliptical and bamboo weaving technology, applied in mechanical equipment, sugarcane machining, etc., can solve problems such as unevenness, unevenness, and poor curvature of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

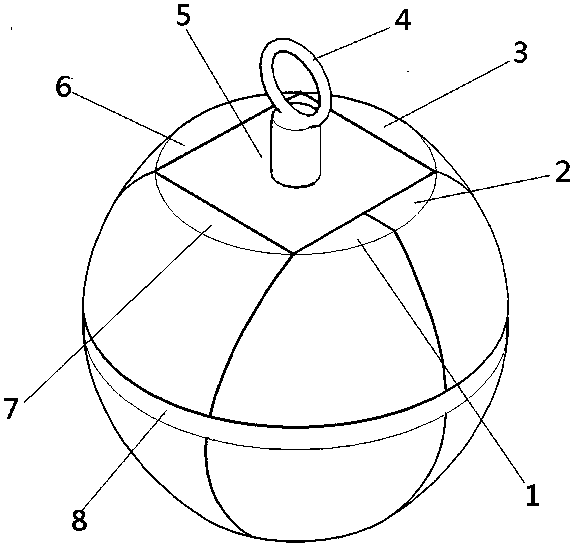

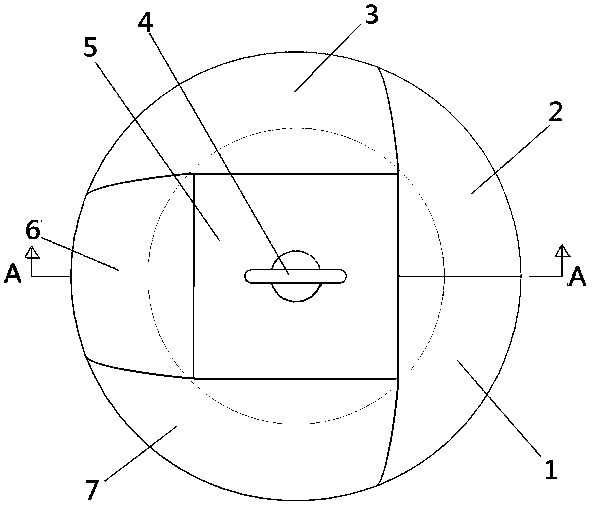

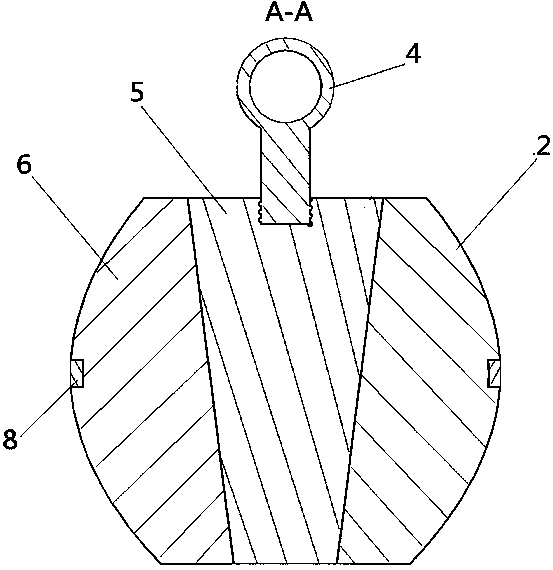

[0024] Below in conjunction with the accompanying drawings and preferred embodiments, a detailed description of the specific implementation, structure, features and effects of the present invention is as follows.

[0025] An elliptical bamboo weaving mold of the present invention is characterized in that: the middle parts of components A1, B2, C3, D6 and E7 are respectively provided with rubber band grooves 9, and ring-shaped rubber bands 8 are snapped into components A1, B2, components In the rubber band grooves 9 provided in the middle of C3, component D6, and component E7, they are combined into an elliptical spherical shape with upper and lower pairs of perforations. The components A1, B2, C3, D6, and E7 are inserted into the center column 5, and the center column 5 Screw in the handle 4 in the screw hole provided at the center above.

[0026] The annular rubber bands 8 are snapped into the rubber band grooves 9 respectively provided in the middle parts of the components A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com