Bending device for hardware machining

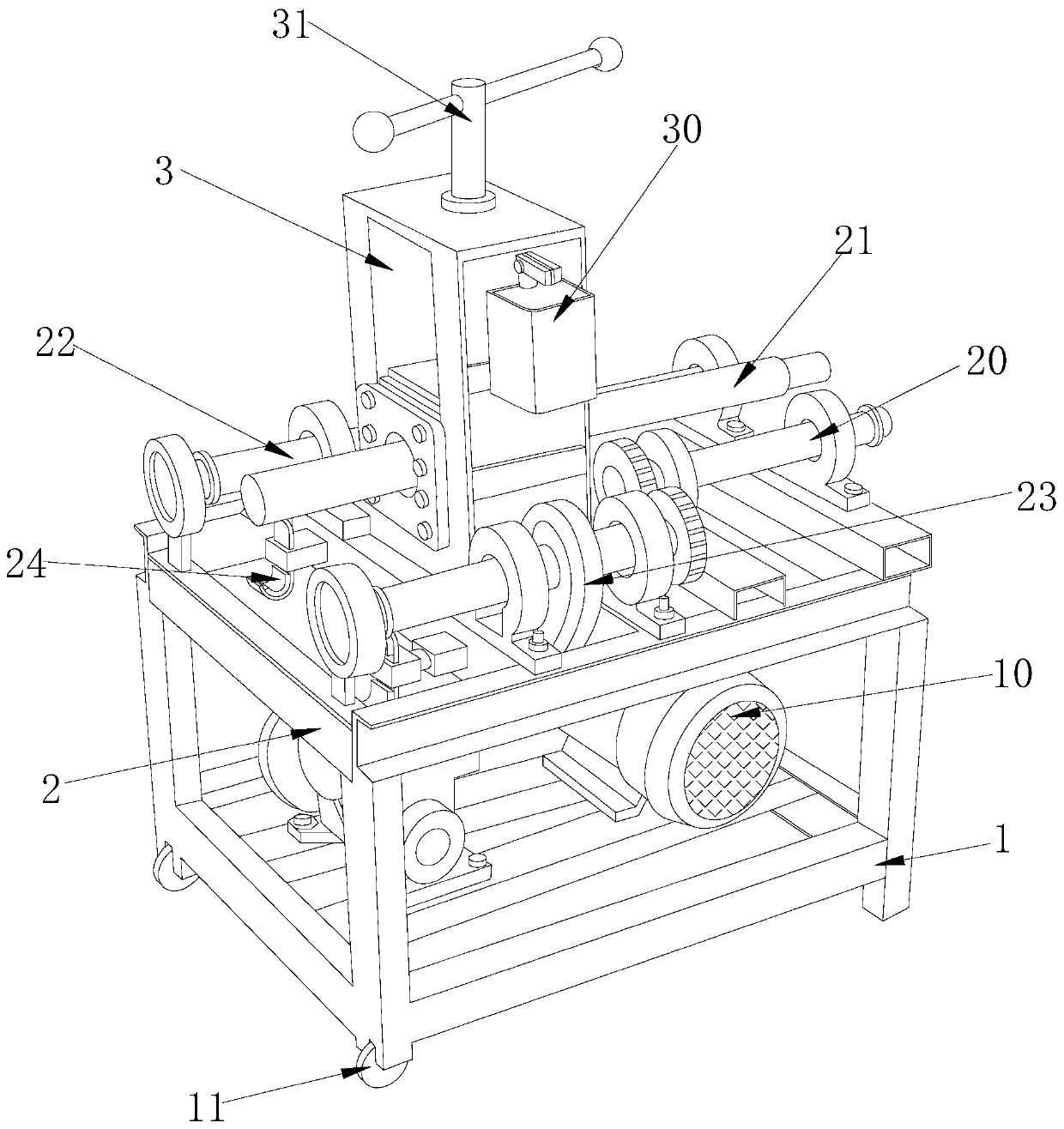

A bending device and hardware technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of affecting the bending process, inconvenient metal tube bending, trouble, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

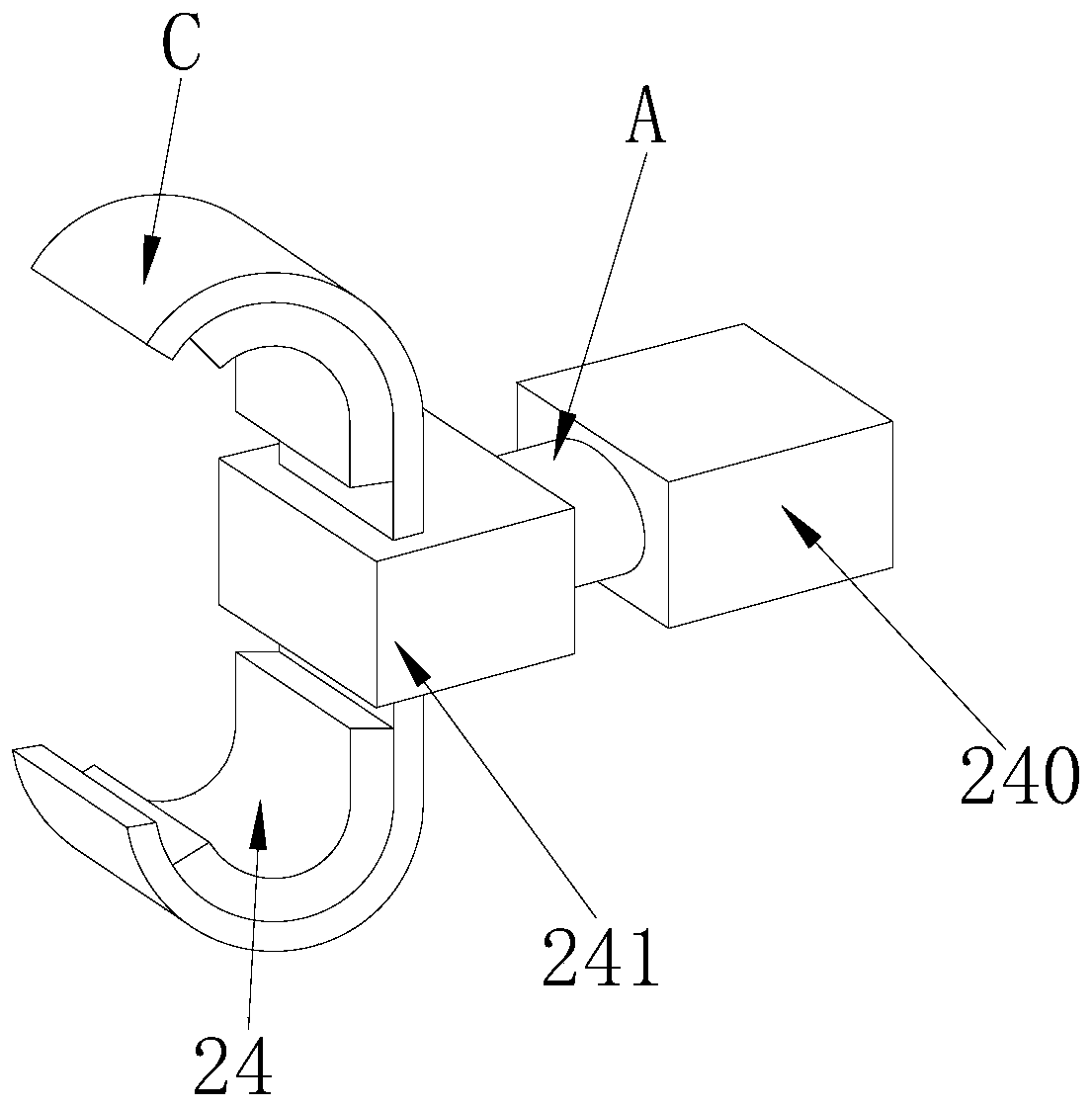

[0029] Embodiment 1: When in use, the clamper 241 is driven by the hydraulic pusher 240 to adjust the distance, and at the same time, it can clamp 1-3 metal tubes, and then squeeze the metal tubes into the clamper 241 to make the clamping The clamp 241 can be opened to reach the maximum diameter of the metal tube, so as to clamp the metal tube; the push rod A on the hydraulic pusher 240 is pushed by the auxiliary push of the sealing ring B to push the clamp 241 to move until it stretches to Put the metal tube into the clamp 241; through the metal tube squeeze between the splints C, so that the splint C is opened, and under the control of the spring D, the splint C is opened to the diameter value suitable for the hardware tube, and at the same time through the spring D Drive splint C to clamp.

Embodiment 2

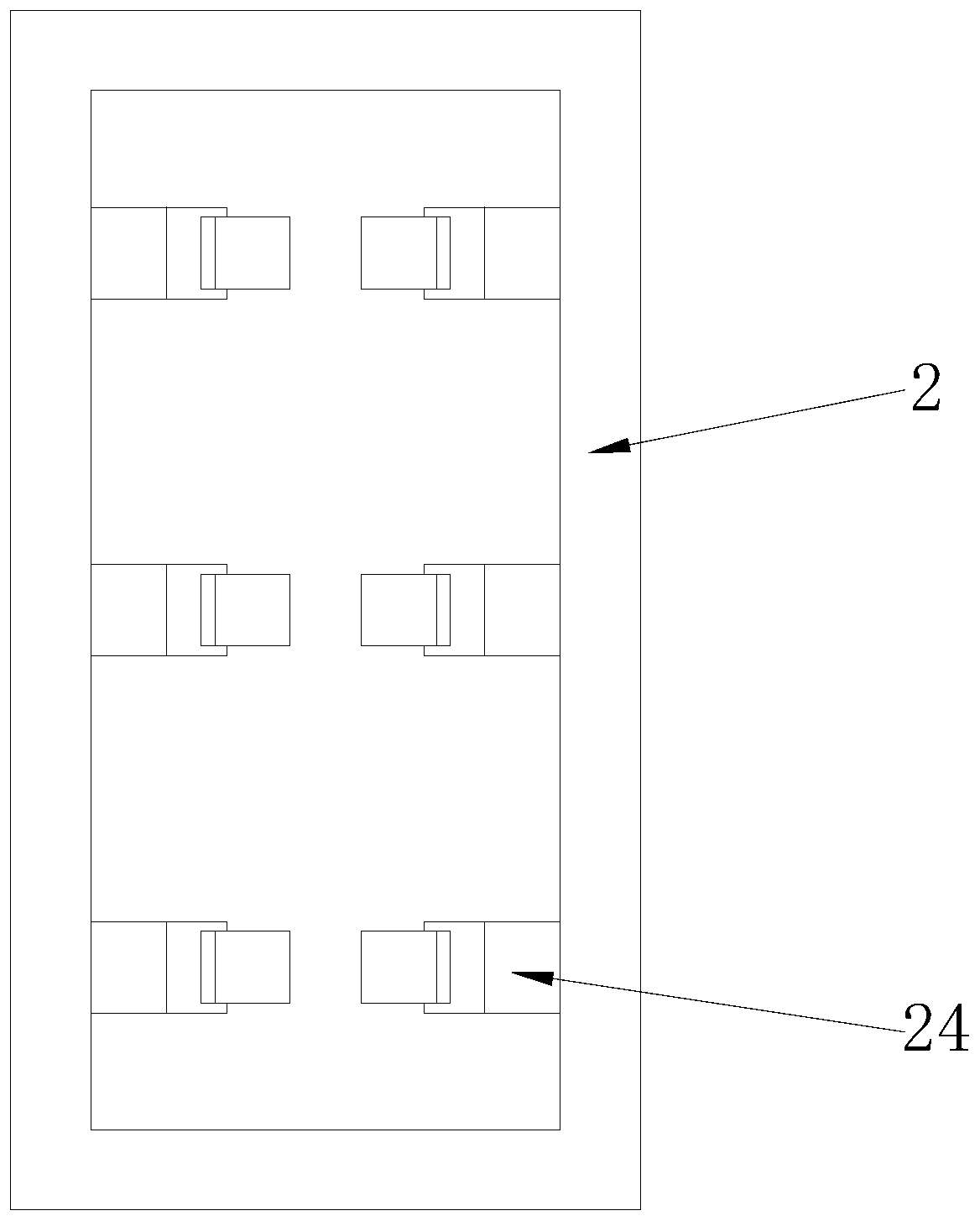

[0030] Embodiment 2: After the clamping work of the metal tube is completed, the splint C is fixed on the clamp 241 through the clamp C1, and at the same time, with the assistance of the cotton pad C2, the metal tube can be bent during the bending process. Sliding in the splint C can ensure the longitudinal sliding of the metal tube while realizing the horizontal clamping of the metal tube, so as to facilitate the bending of the metal tube by assisting the left idler 20, the pressure roller 21 and the right idler 22 fold work.

[0031] The technical progress that the present invention obtains relative to the prior art is:

[0032] 1. Push the clamp to clamp the metal tube through the hydraulic pusher, and at the same time make the limit clamp suitable for one or more metal tubes for simultaneous bending processing. By squeezing the metal tube into the clamp, Then, it is clamped by the spring and the splint, so as to realize the horizontal fixation of the metal tube;

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com