Automatic oil scraping system for swill separation and automatic oil scraping method thereof

An oil system and automatic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of low oil volume and low oil scraping efficiency, and achieve the effect of large oil scraping volume and high oil scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

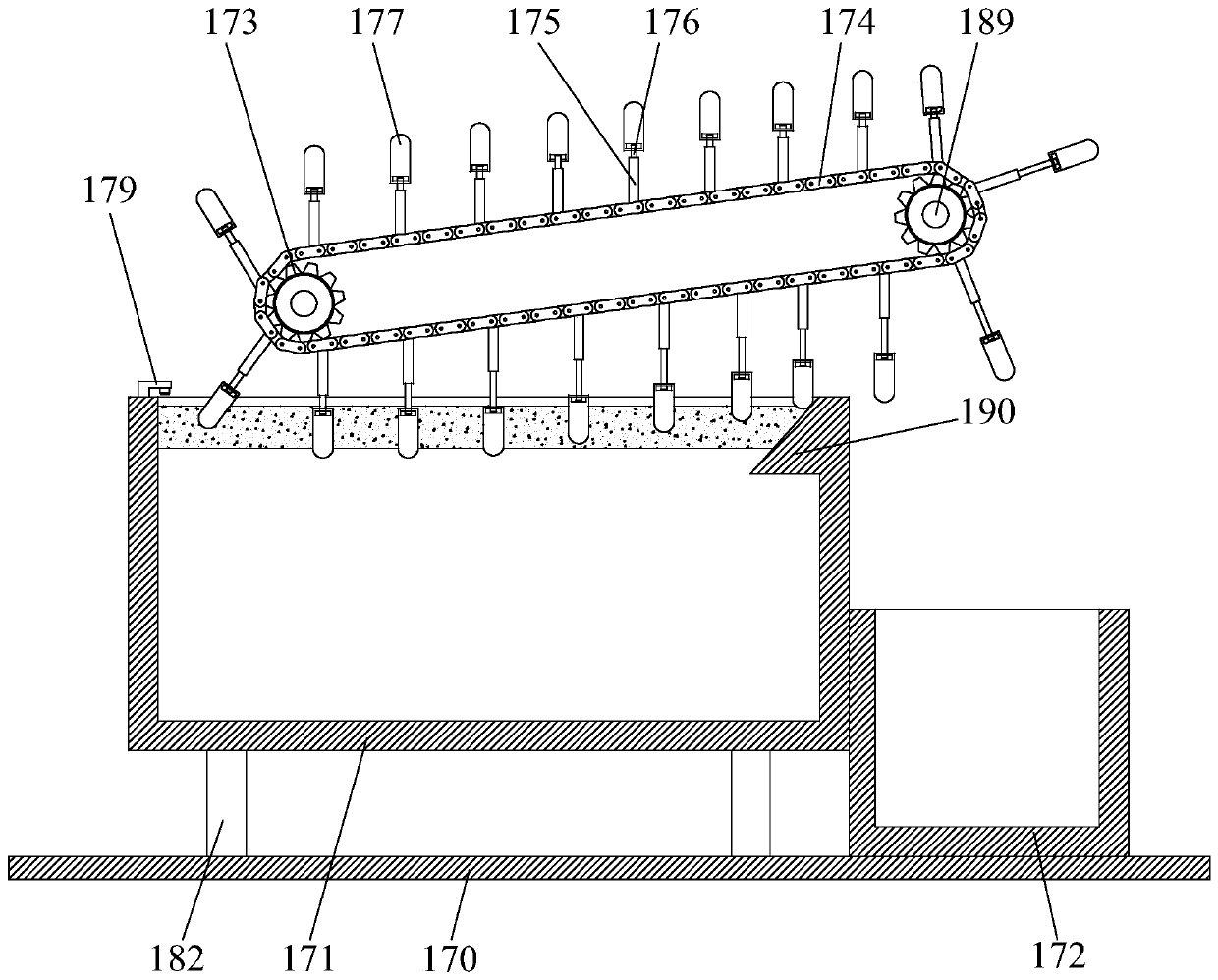

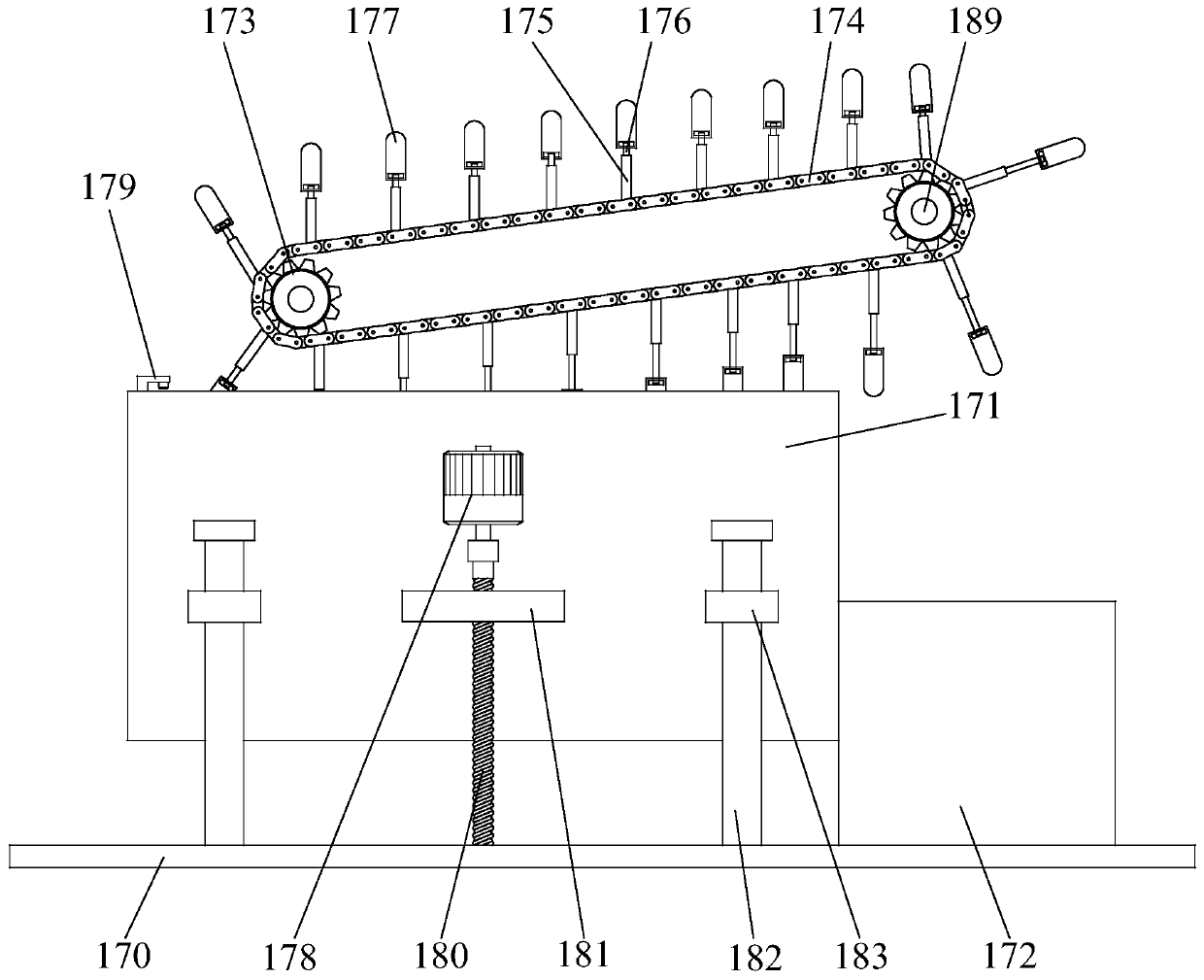

[0052] see figure 1 , figure 2 as well as image 3 , this embodiment provides an automatic oil scraping system for swill separation, the system is used to scrape the oil-water mixture / liquid produced in the kitchen swill separation process, can extract oil, and can also remove part of the scum collect. Wherein, the automatic oil scraping system includes an oil scraping rack 170, a storage tank 171, an oil collecting tank 172, an automatic oil scraping mechanism, a lifting mechanism, a liquid level sensor 179 and an oil scraping controller.

[0053] The oil scraper frame 170 is composed of a plurality of square tubes spliced together, and the splicing method can be welding, clamping, screwing, etc., and of course it can also be integrally formed. The bottom end of the oil scraper frame 170 can be provided with structures such as pulleys, so that the oil scraper frame 170 can move on the ground. At the same time, the bottom of the oil scraper frame 170 can also be provide...

Embodiment 2

[0066] see Figure 4 , This embodiment provides an automatic oil scraping system for swill separation, which is similar to the automatic oil scraping system in Embodiment 1, the difference lies in the structure of the drive assembly. The driving assembly includes telescopic elements 185, and there are at least two telescopic elements 185, and the two telescopic elements 185 expand and contract synchronously. Wherein, the driving amount is the amount of expansion and contraction of the expansion member 185 . The lifting assembly includes side plates 184 , the number of side plates 184 is at least two, and the at least two side plates 184 correspond to at least two telescopic elements 185 respectively. The automatic oil scraping mechanism is fixed between two side plates 184 . Each telescopic member 185 is fixed on the oil scraper frame 170 , and the telescopic end is connected to the corresponding side plate 184 . The structure of the driving assembly in this embodiment is s...

Embodiment 3

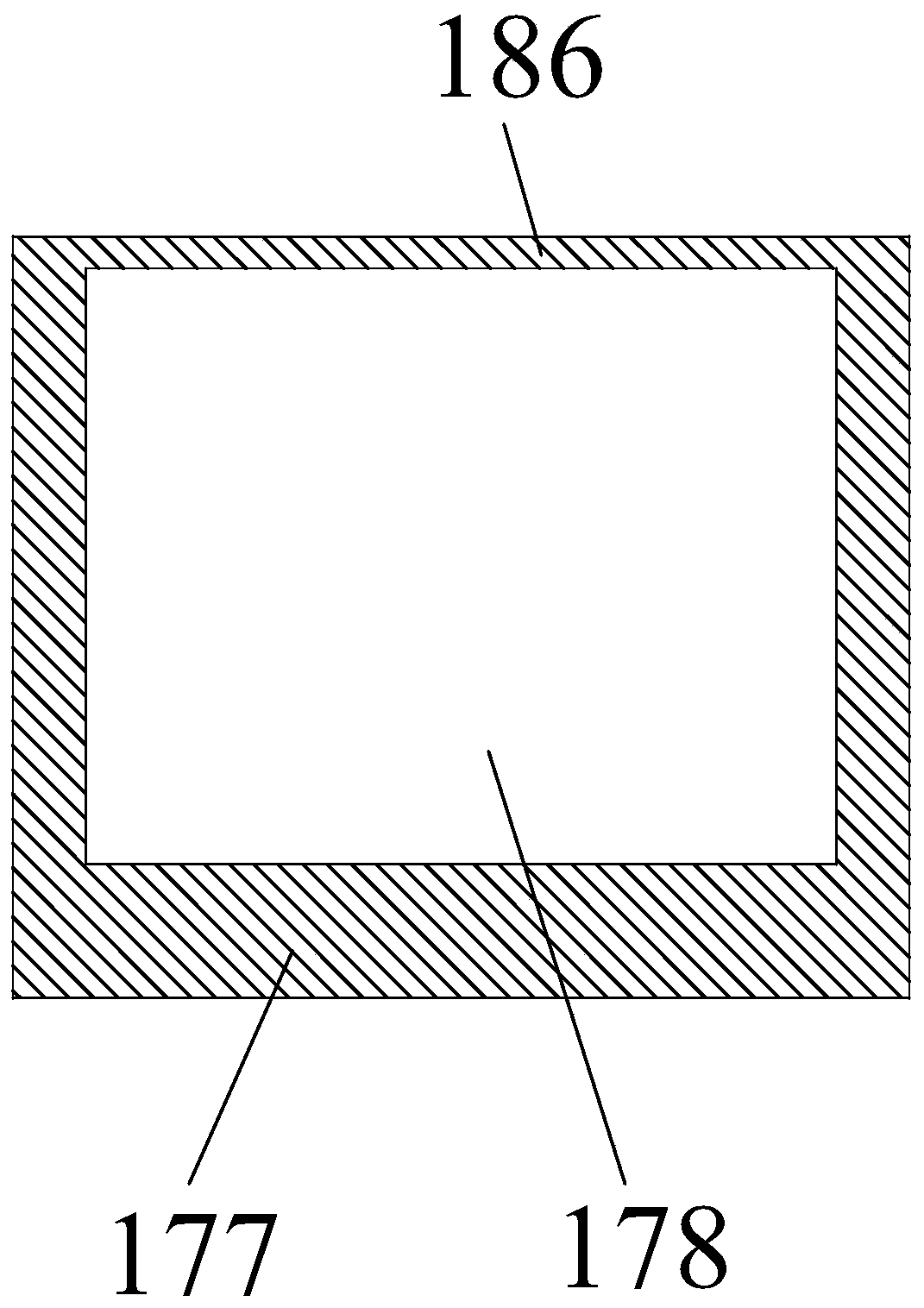

[0068] see Figure 5 , This embodiment provides an automatic oil scraping system for swill separation, which is similar to the system in Embodiment 1, the difference is that the oil scraper block 177 is spherical, and the oil storage tank 178 is opened in the center of the oil scraper block 177 and is spherical. In this way, the surface of the oil scraper block 177 will be smoother, and at the same time, when the area of the outer surface is the smallest, the internal space thereof can be maximized, and the oil can be fully accommodated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com