A multi-dimensional detection method for partial discharge of transformer bushing

A transformer bushing and partial discharge technology, which is applied in the direction of using optical methods for testing, instruments, and measuring electricity, can solve problems such as long recovery time, wide range of fault influence, and unstable measurement accuracy, and achieve good complementarity and completeness and the effect of effective analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above objects, features and advantages of the present application more clearly understood, the specific embodiments of the present application will be described in detail below with reference to the accompanying drawings.

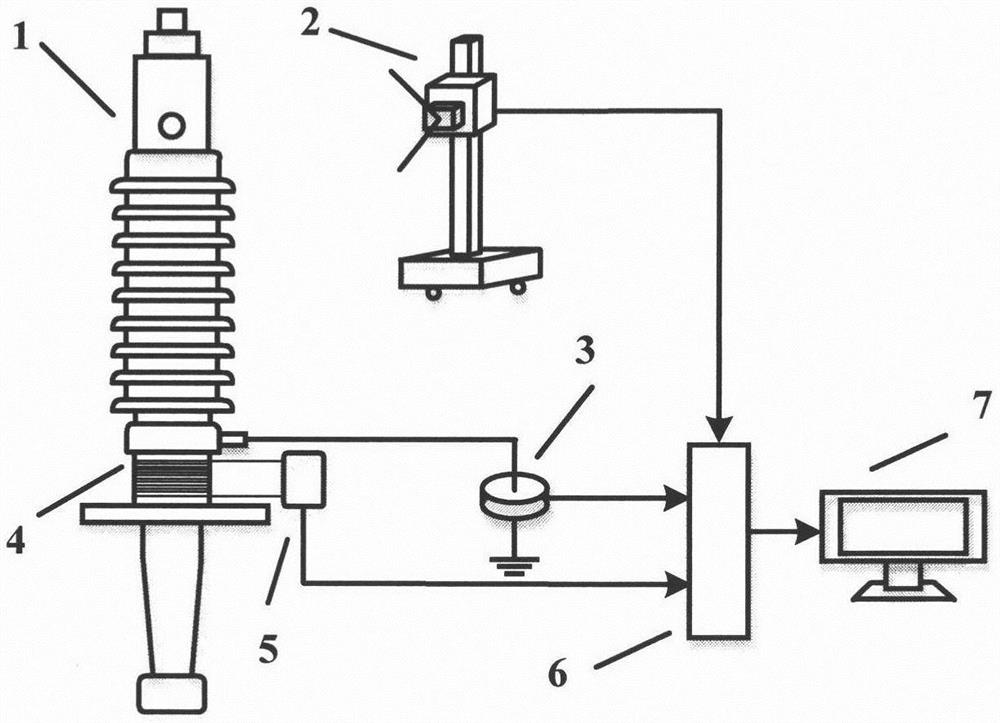

[0020] like figure 1 As shown, the present invention provides a transformer bushing partial discharge monitoring system, a transformer bushing 1, a UHF sensor 2, a high-frequency current sensor 3, a sensing fiber 4, a photoelectric converter 5, a data synchronization transmission unit 6 and Host computer 7.

[0021] The UHF sensor 2 is placed outside the casing and has no contact with the casing. The high-frequency current sensor 3 is installed on the ground wire of the end screen of the casing. The sensing fiber 4 is wound on the surface of the casing flange, and the output optical signal passes through the photoelectric The converter 5, the UHF signal and the high frequency current signal are input to the upper computer 7 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com