Drilling device used for ground deep hole blasting

A technology of deep hole blasting and drilling equipment, which is applied in the direction of support equipment, earthwork drilling, drilling equipment, etc., to achieve smooth progress, eliminate excessive swing range, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

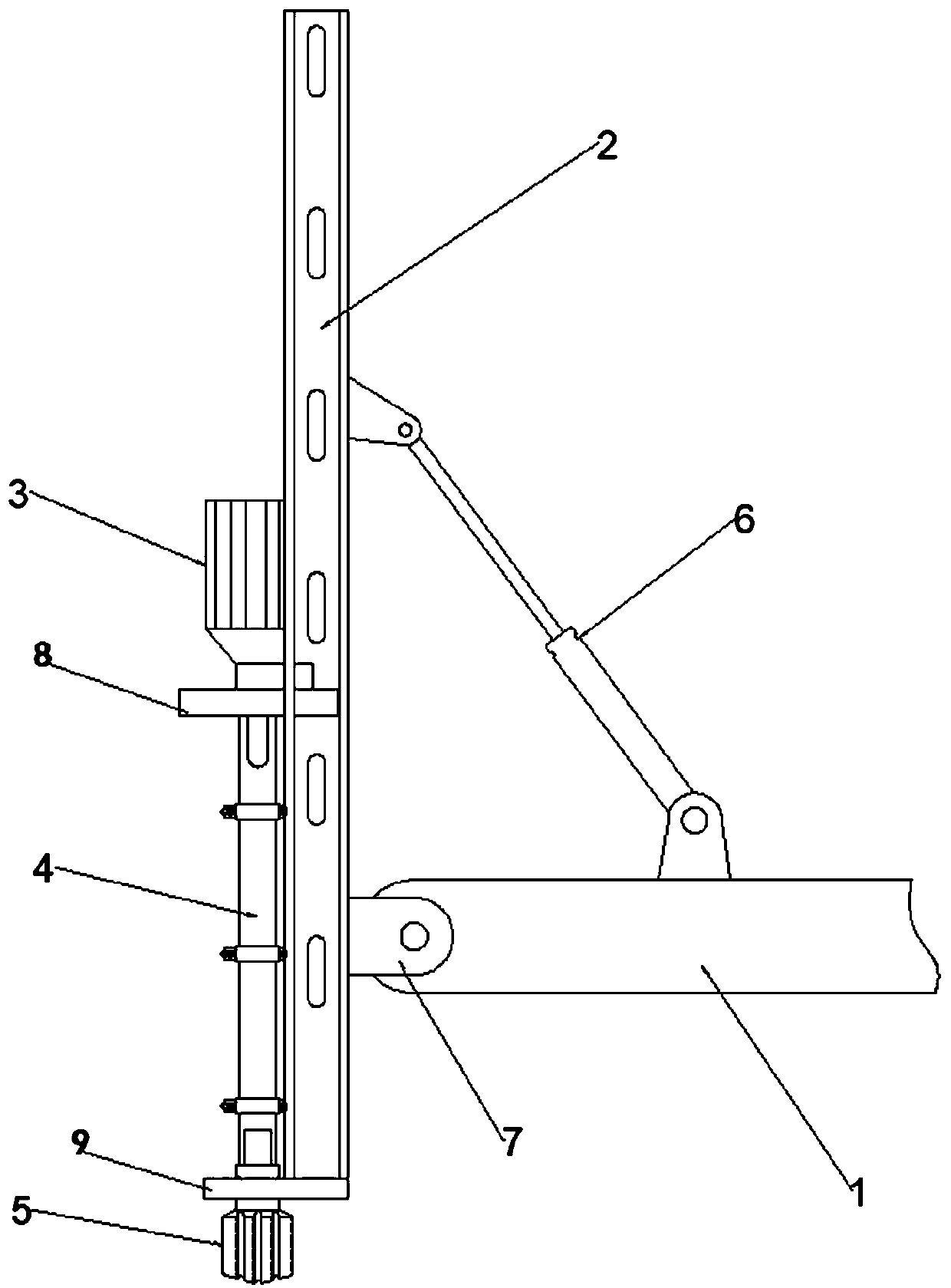

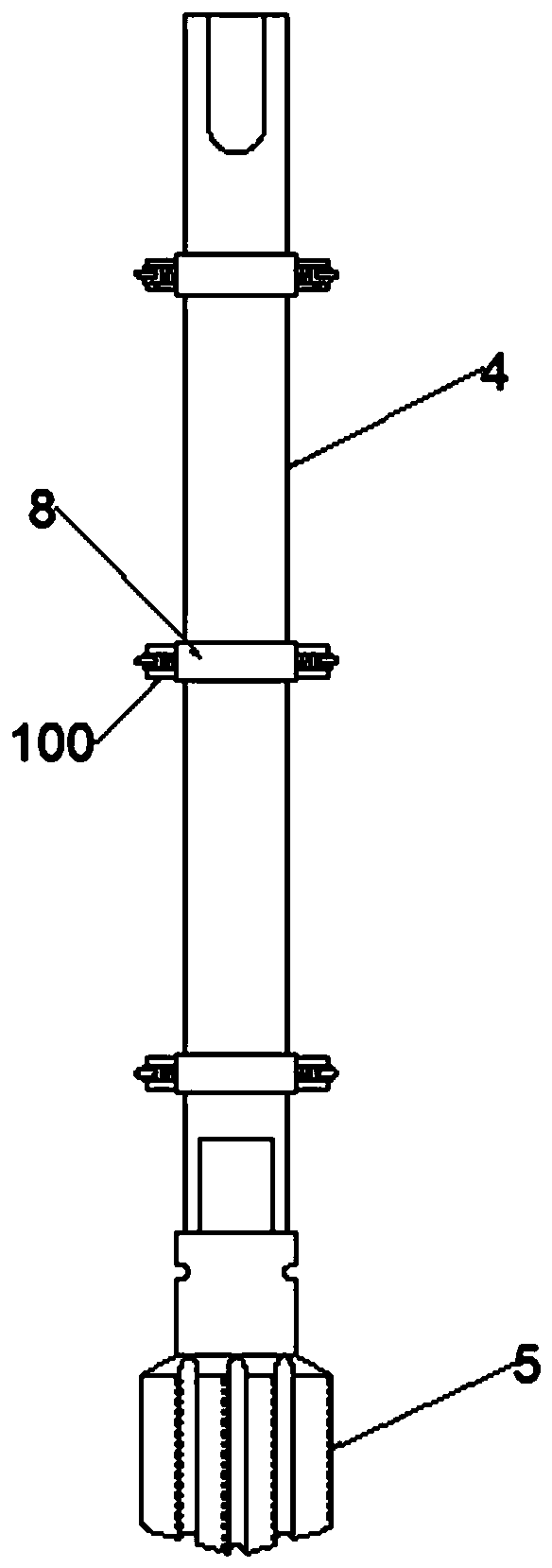

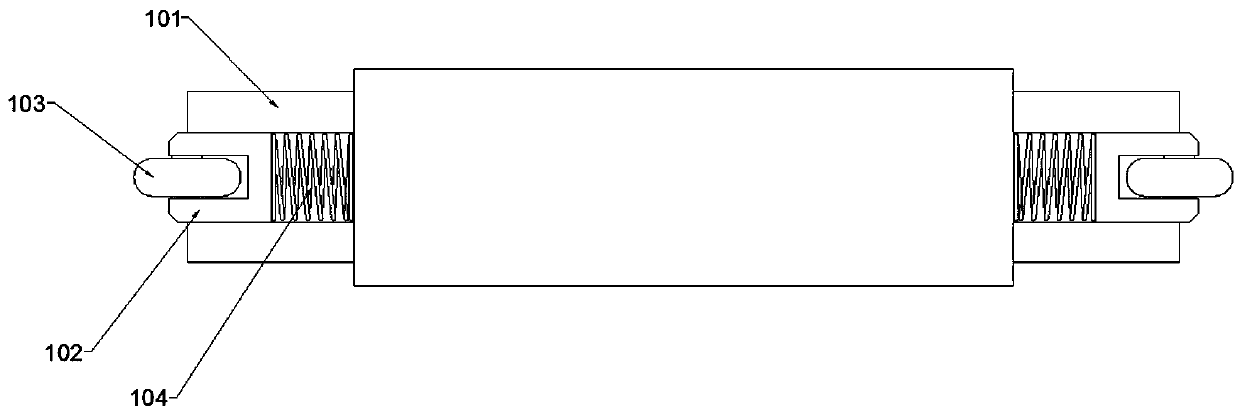

[0030] like figure 1 As shown, a drilling device for ground deep hole blasting includes a fixed platform 1, a sliding seat 2, a drilling rig 3, a screw rod 4, a drill bit 5 and an auxiliary cylinder 6. The sliding seat 2 is essentially a sliding frame, and its length can be designed according to the model of the product. There is a hinged joint 7 on one side of the sliding seat 2, and the sliding seat 2 is hinged on the fixed platform 1 through the hinged joint 7. The fixed platform 1 is set On stationary racks or vehicles. The auxiliary cylinder 6 is connected between the sliding seat 2 and the fixed platform 1, and the elevation angle of the sliding seat 2 is adjusted through the auxiliary air cylinder 6, and the elevation angle adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com