Underground pipeline protective construction method for subway construction

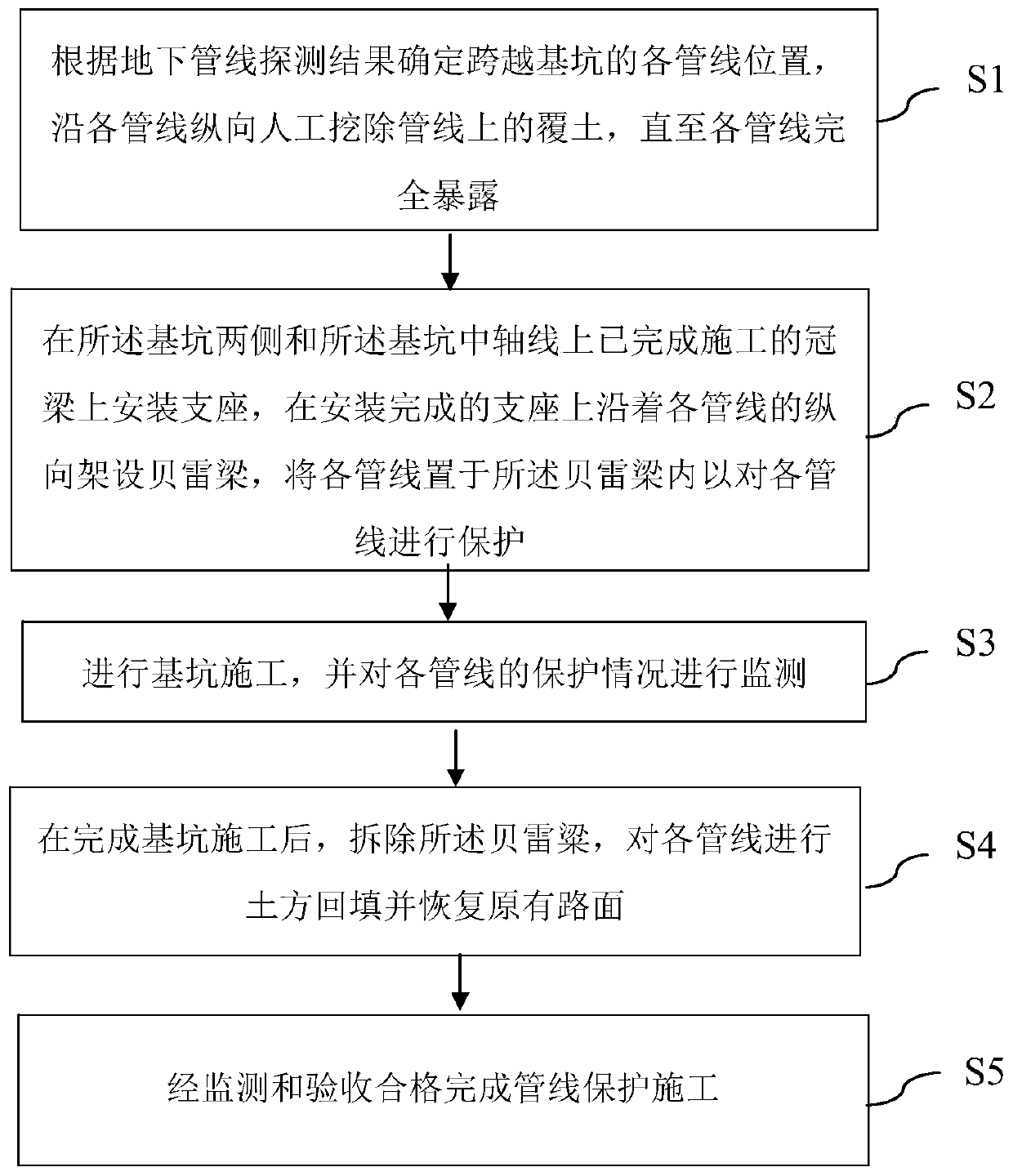

A construction method and underground pipeline technology, which can be used in excavation, artificial islands, water conservancy projects, etc., can solve problems such as pipeline breakage, fire explosion, gas leakage, etc., and achieve uniform force, high construction efficiency, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

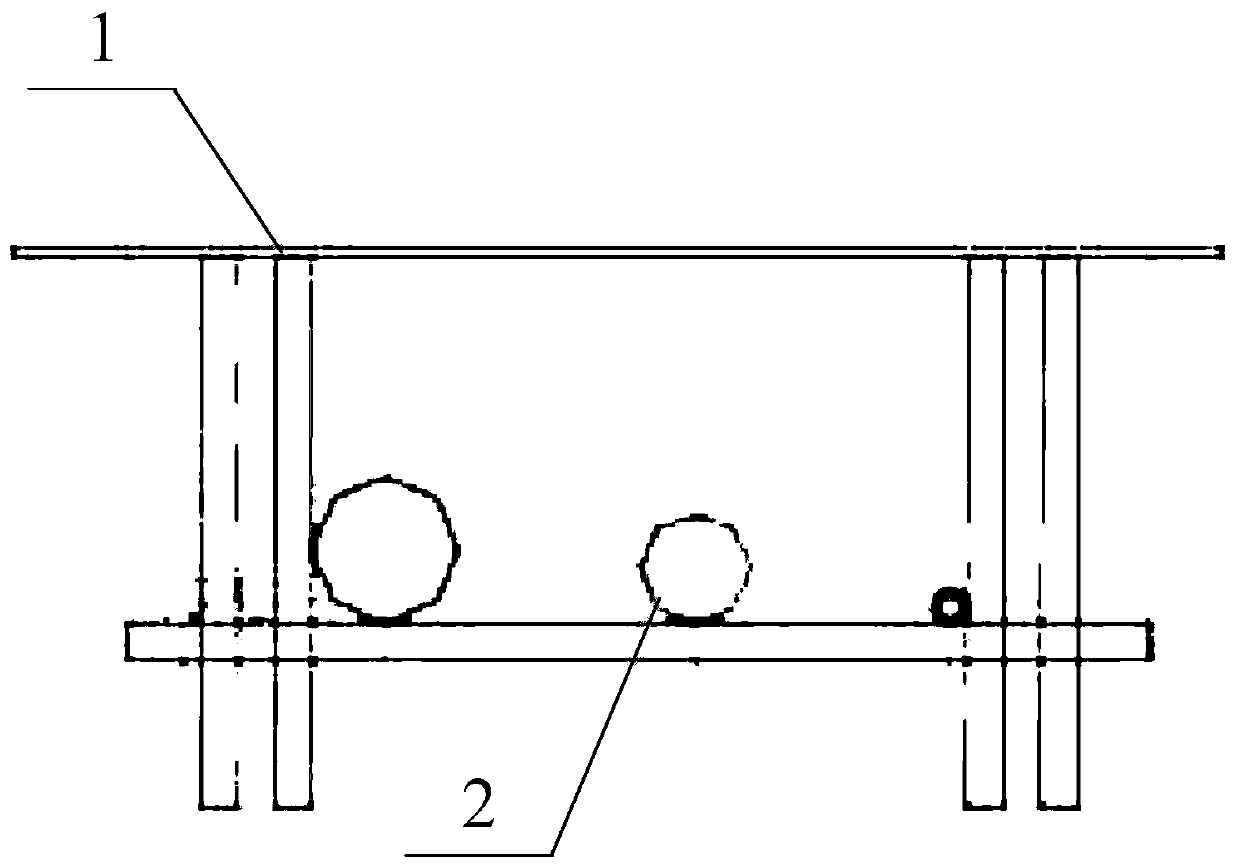

[0031] According to an embodiment of the present invention, preferably, the step S2) further includes: before erecting the Bailey beam 1, checking the mechanical properties of the design structure of the Bailey beam 1 to confirm that the Bailey beam 1 Thunder beam 1 meets the construction requirements. Wherein performing the mechanical characteristic checking includes: selecting corresponding calculation parameters according to the structure of the Bailey beam 1, calculating the force calculation of the Bailey beam 1 of the structure; calculating the Bailey beam design load of the Bailey beam 1, determining The Bailey beam 1 meets the design requirements and ensures the safety of construction.

[0032] According to the technical solution of the present invention, step S3) carries out foundation pit construction, and monitors the protection conditions of each pipeline 2, so as to ensure effective protection of each pipeline 2 and ensure construction safety.

[0033] According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com