Flexible compression roller suitable for automatic inclined laying forming of special-shaped structure

An automatic and laying technology, which is applied in the field of flexible pressure rollers, can solve problems such as the inability to meet the needs of adaptive laying of special-shaped composite materials/metal structures, and achieve the requirements of adaptive laying, reducing control difficulty, and improving work reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

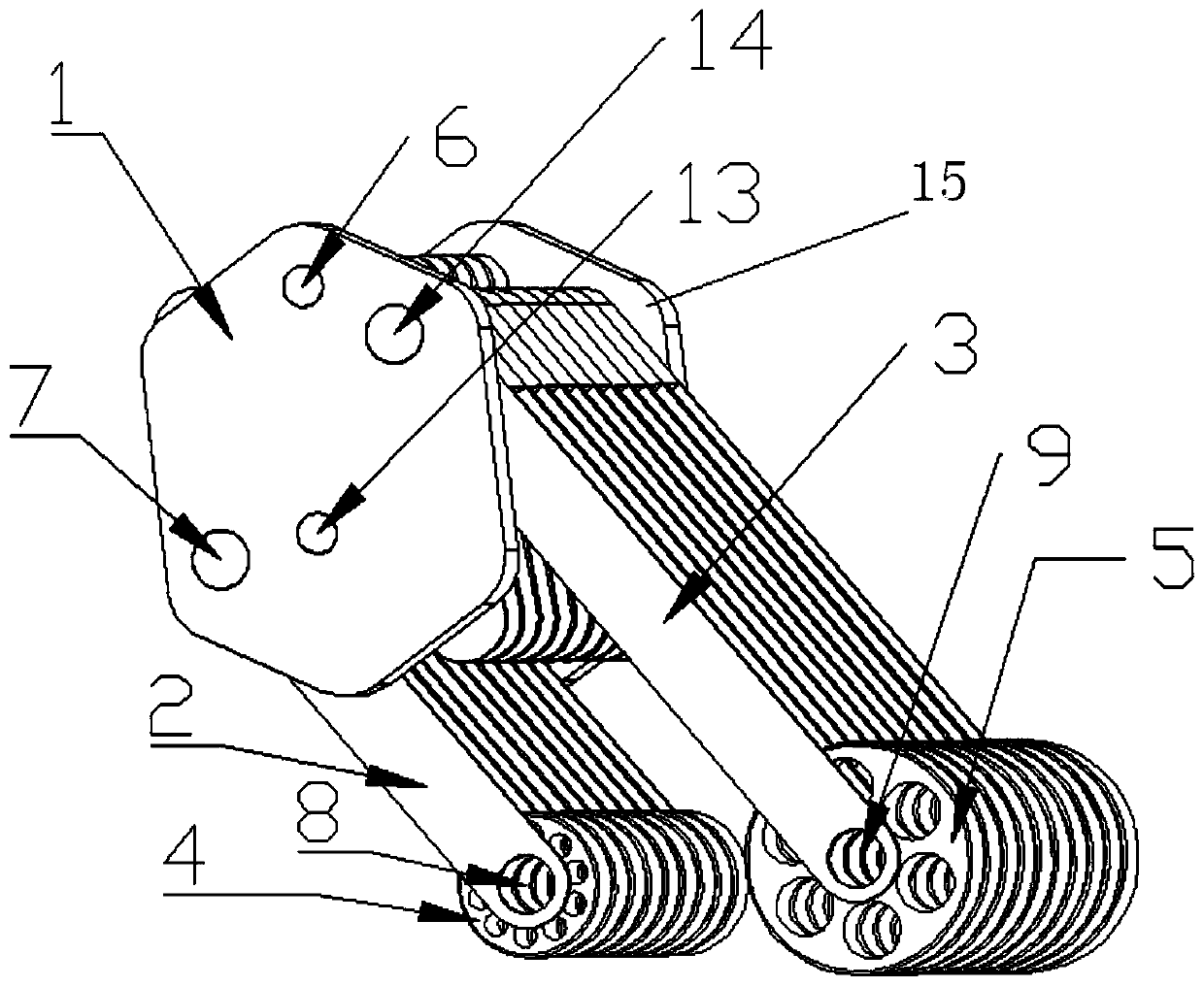

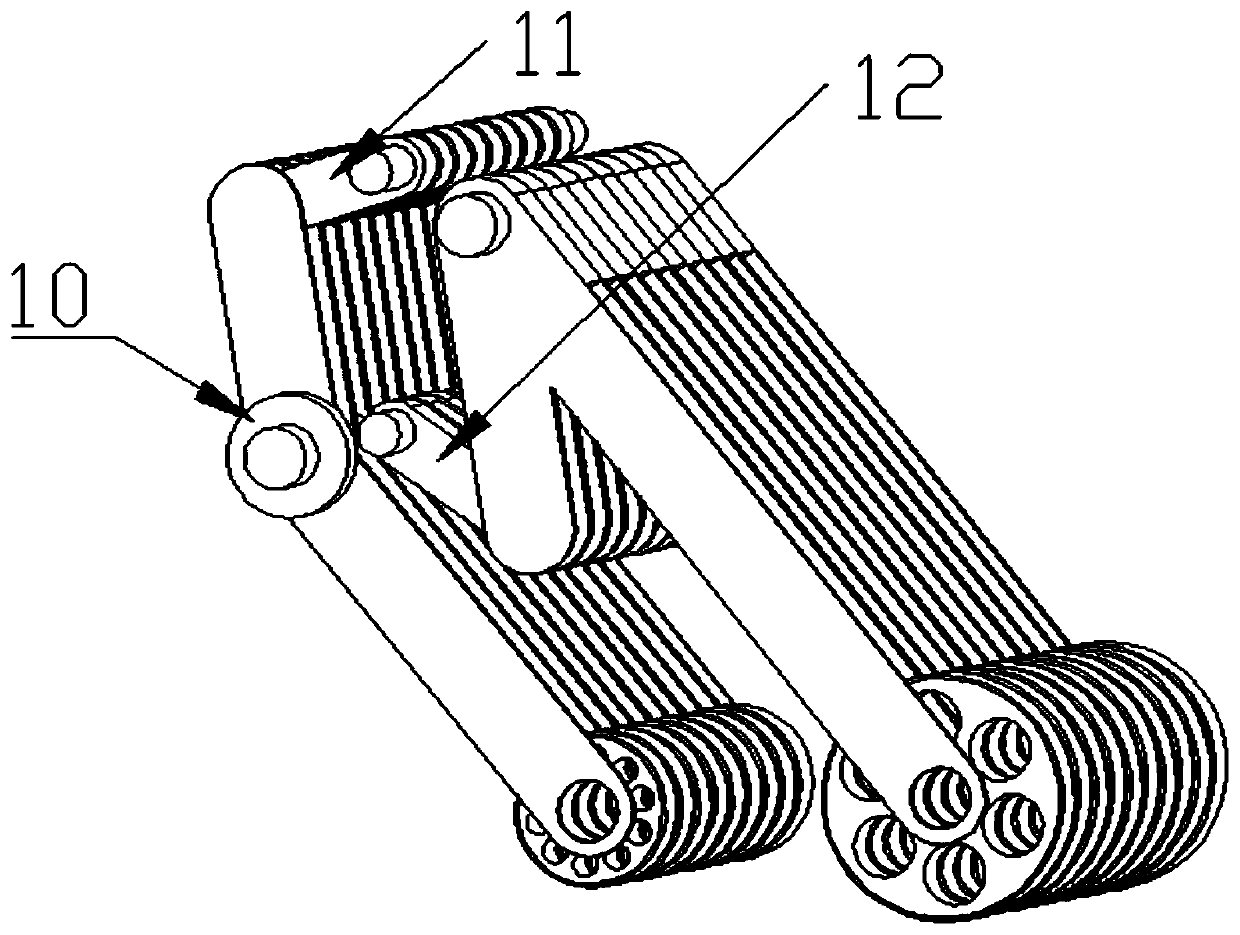

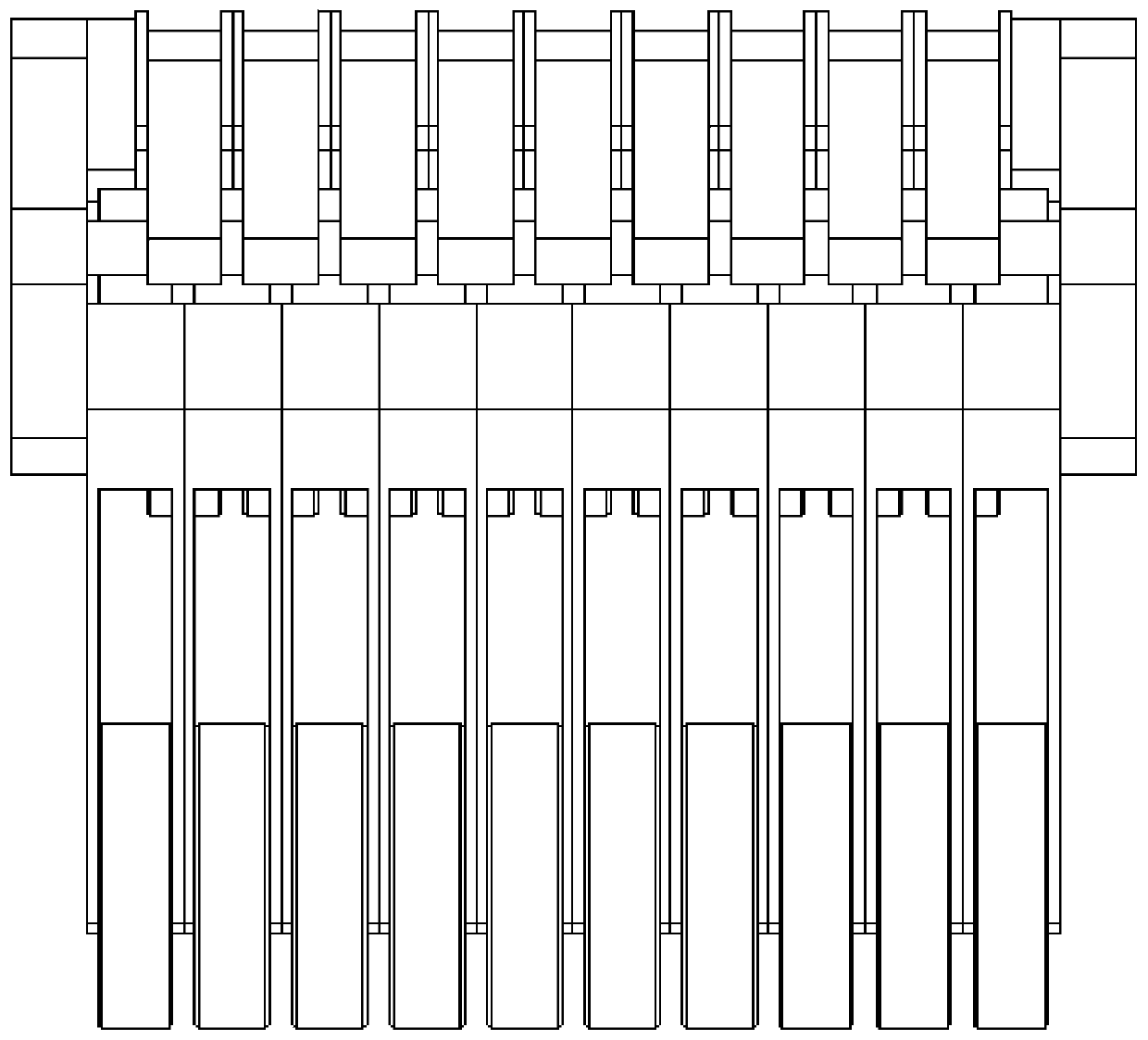

[0026] The present invention will be described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1~3 As shown, a flexible pressure roller suitable for automatic inclined laying and forming of special-shaped structures includes a left baffle 1, a right baffle 15, a first follower link 2, a second follower link 3, and a first roller 4. , the second roller 5, the first baffle link 6, the second baffle link 7, the first roller link 8, the second roller link 9, the gasket 10, the first follower spring 11, the second follower Moving spring 12, the third baffle plate connecting rod 13, the fourth baffle plate connecting rod 14.

[0028] Both the first follower link 2 and the second follower link 3 are bent rods, the bending angle of the first follower link 2 is an obtuse angle or a right angle, and the bend angle of the second follower link 3 is an acute angle or a right angle; N first follower links 2 are arranged in sequence, and are connected to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compression force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com