Efficient sludge discharge purifying device for sewage treatment

A sewage treatment and purification device technology, applied in chemical instruments and methods, filtration and separation, fixed filter element filters, etc., can solve problems affecting the normal progress of sewage treatment, increase sewage treatment costs, and user workload, etc., to achieve maintenance And the effect of convenient and quick replacement, easy promotion and implementation, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

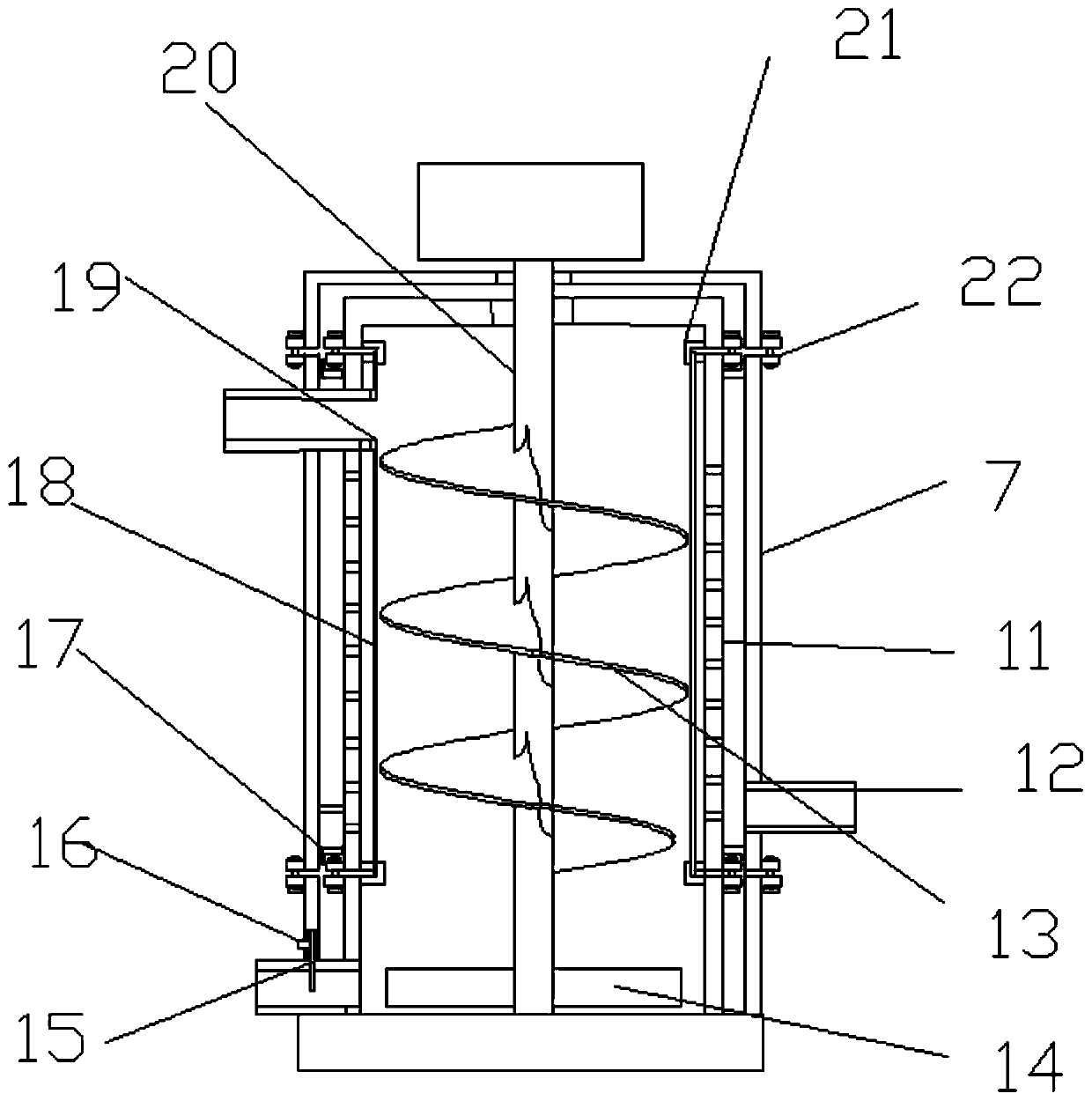

[0027] see Figure 1-6 , a high-efficiency sludge discharge purification device for sewage treatment, comprising a bottom plate 1, a water pump 2 and a purification cylinder 3. The four corners of the lower surface of the base plate 1 are provided with universal wheels 8, and the universal wheels 8 are provided with clamping plates, which have a braking effect on the universal wheels 8, and the universal wheels 8 are convenient for moving and fixing the device. The upper surface of the base plate 1 is fixedly equipped with a purification cylinder 3 and a water pump 2. The purification cylinder 3 includes a top cover 4, a cylinder body 7 and a cylinder seat 10. The top cover 4, the cylinder body 7 and the cylinder base 10 are connected by a flange 22, thereby It is convenient to assemble and install the purification cartridge 3 . The outer top of the purification cylinder 3 is fixedly equipped with a motor 5, the output shaft of the motor 5 extends into the interior of the pur...

Embodiment 2

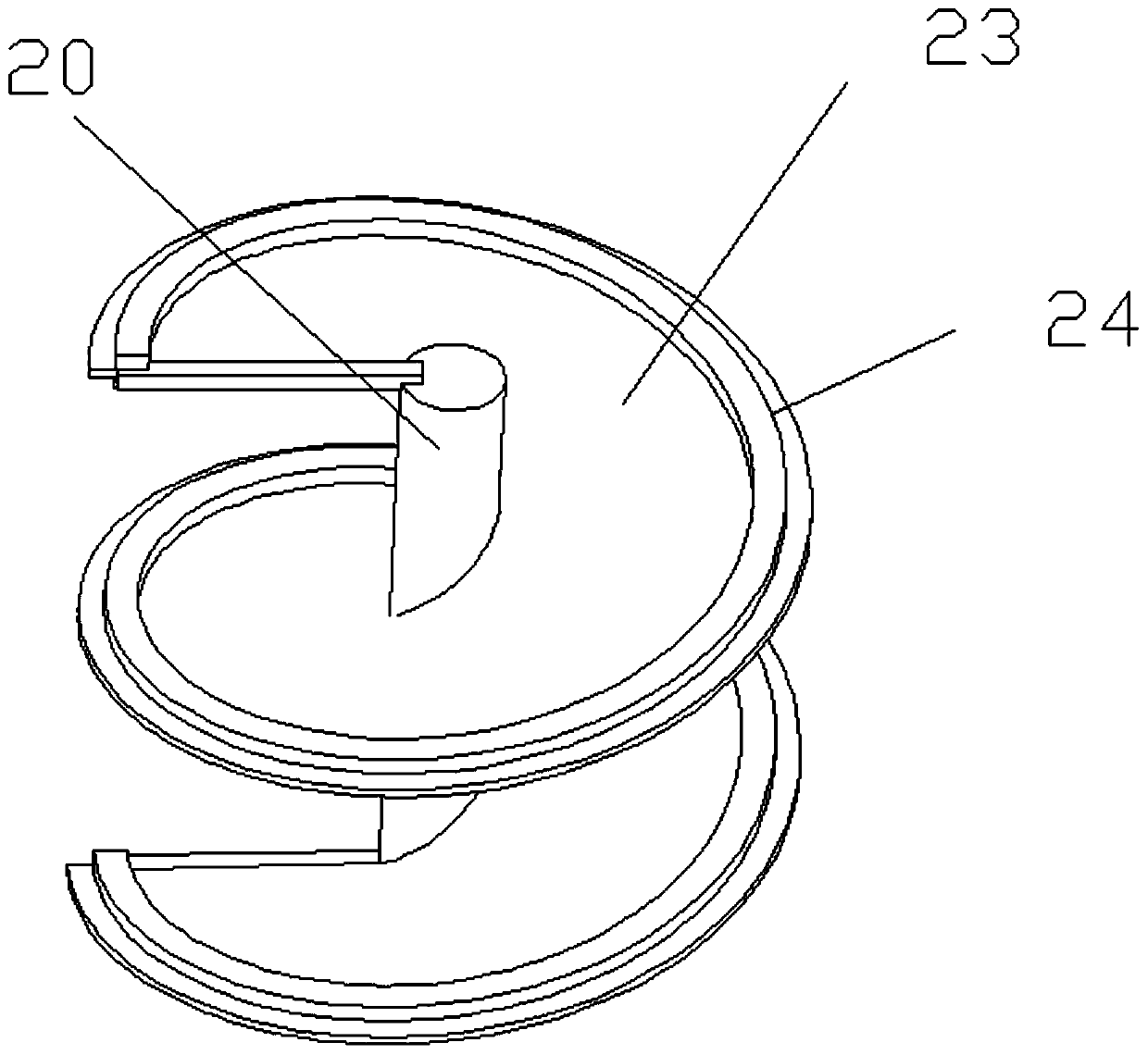

[0032] On the basis of Embodiment 1, the spiral scraper 13 includes a spiral plate 23 and a scraper strip 24, the spiral plate 23 is fixedly connected on the rotating shaft 20, the scraper strip 24 is fixedly arranged on the outer edge of the spiral plate 23, and the spiral plate 23 As the rotating shaft 20 rotates, the filtration pressure is increased, thereby improving the treatment efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com