Motor iron core structure

A technology of iron core structure and core body, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of falling off, high friction force of inserts, and insufficient inserts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

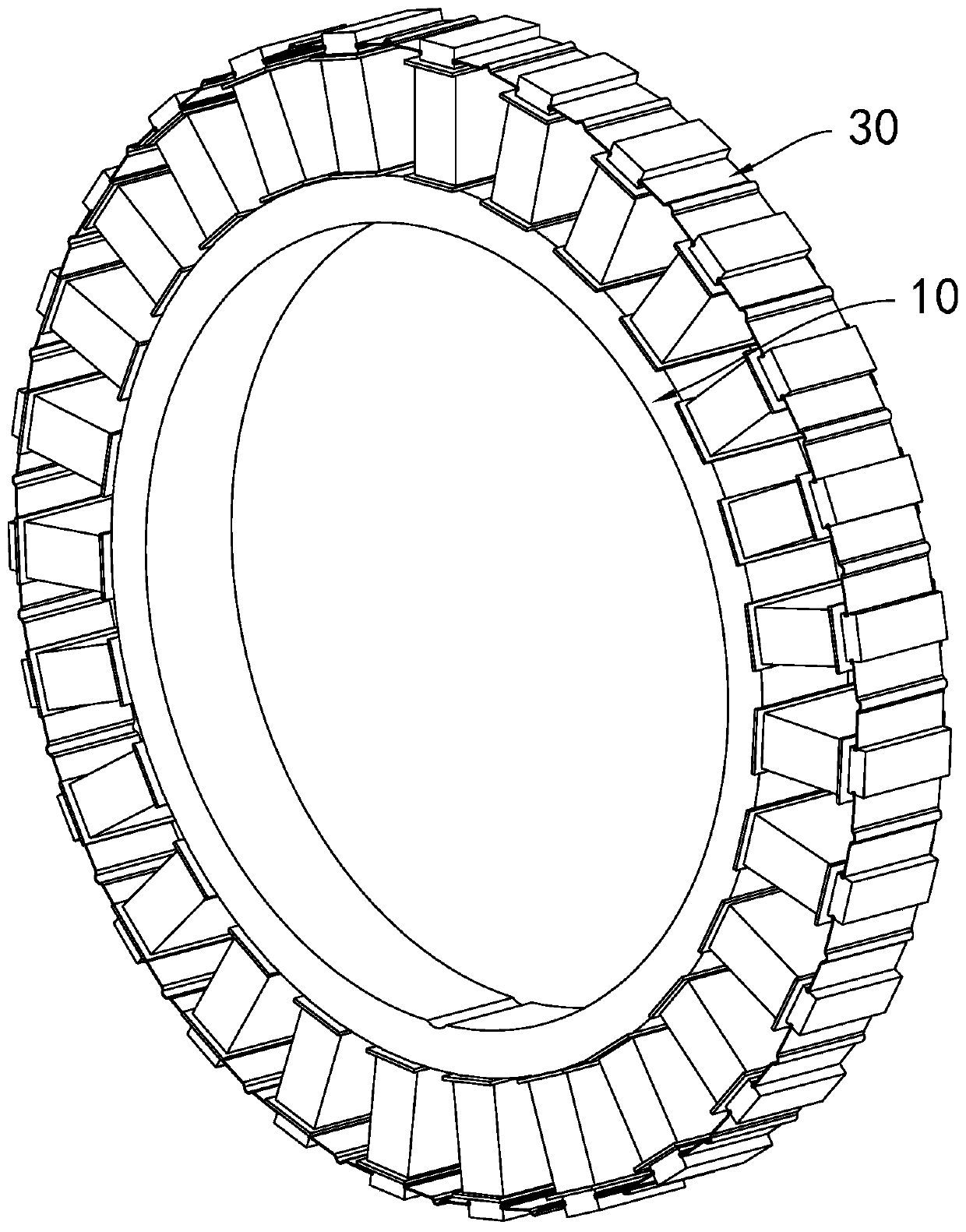

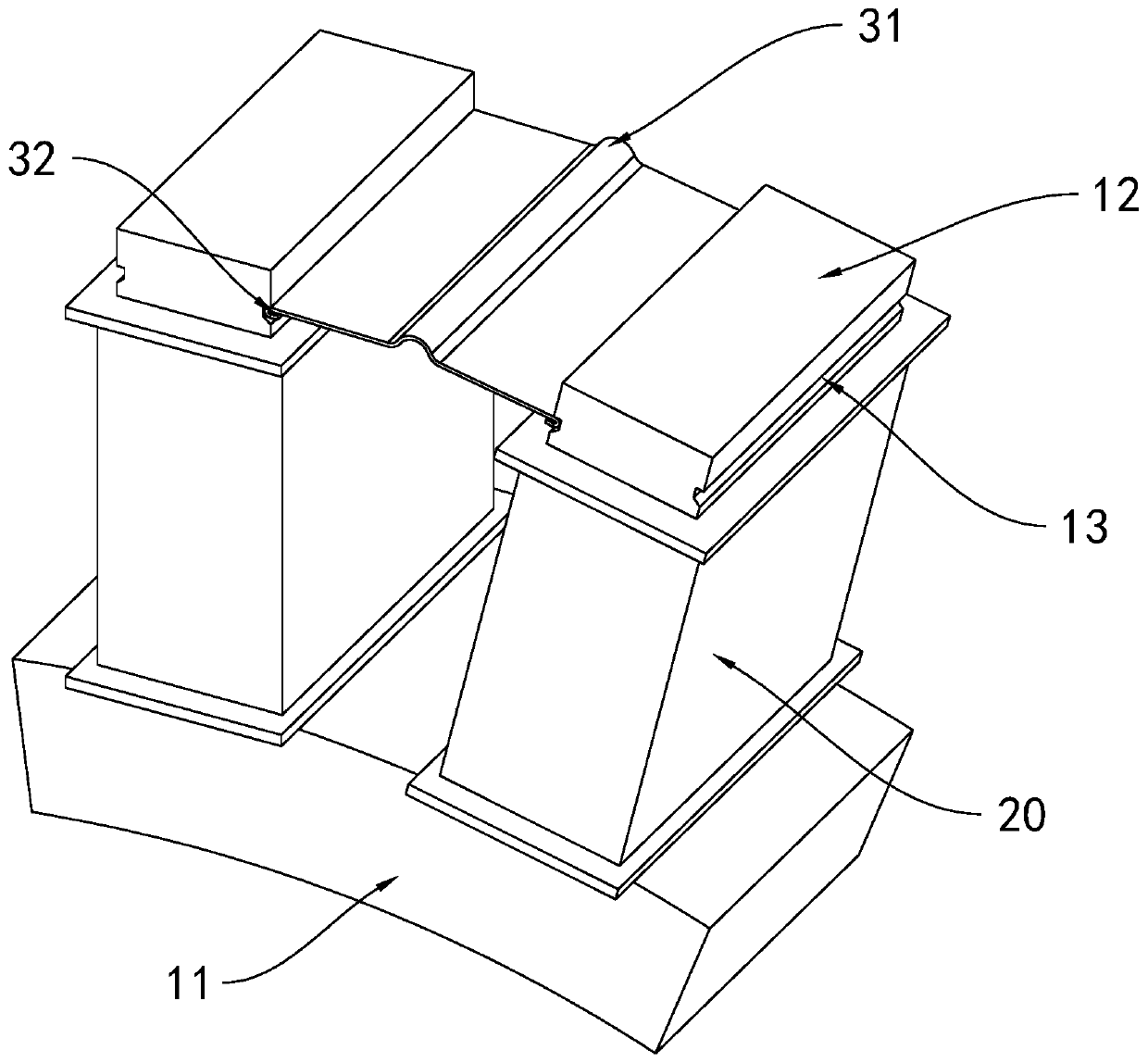

[0019] Embodiment: A motor core structure, including a core body 10, the core body 10 includes a ring-shaped yoke part 11, and teeth parts 12 are distributed around the outside of the yoke part 11. The tooth part 12 is a cuboid structure, the tooth part 12 is radially covered with an insulating case 20 , and a winding wire is wound around the insulating case 20 . It also includes an insertion piece 30 for limiting the radial position of the insulating case 20 , and an axial groove 13 is provided on the side of the tooth portion 12 , and the groove 13 is matched with the insertion piece 30 .

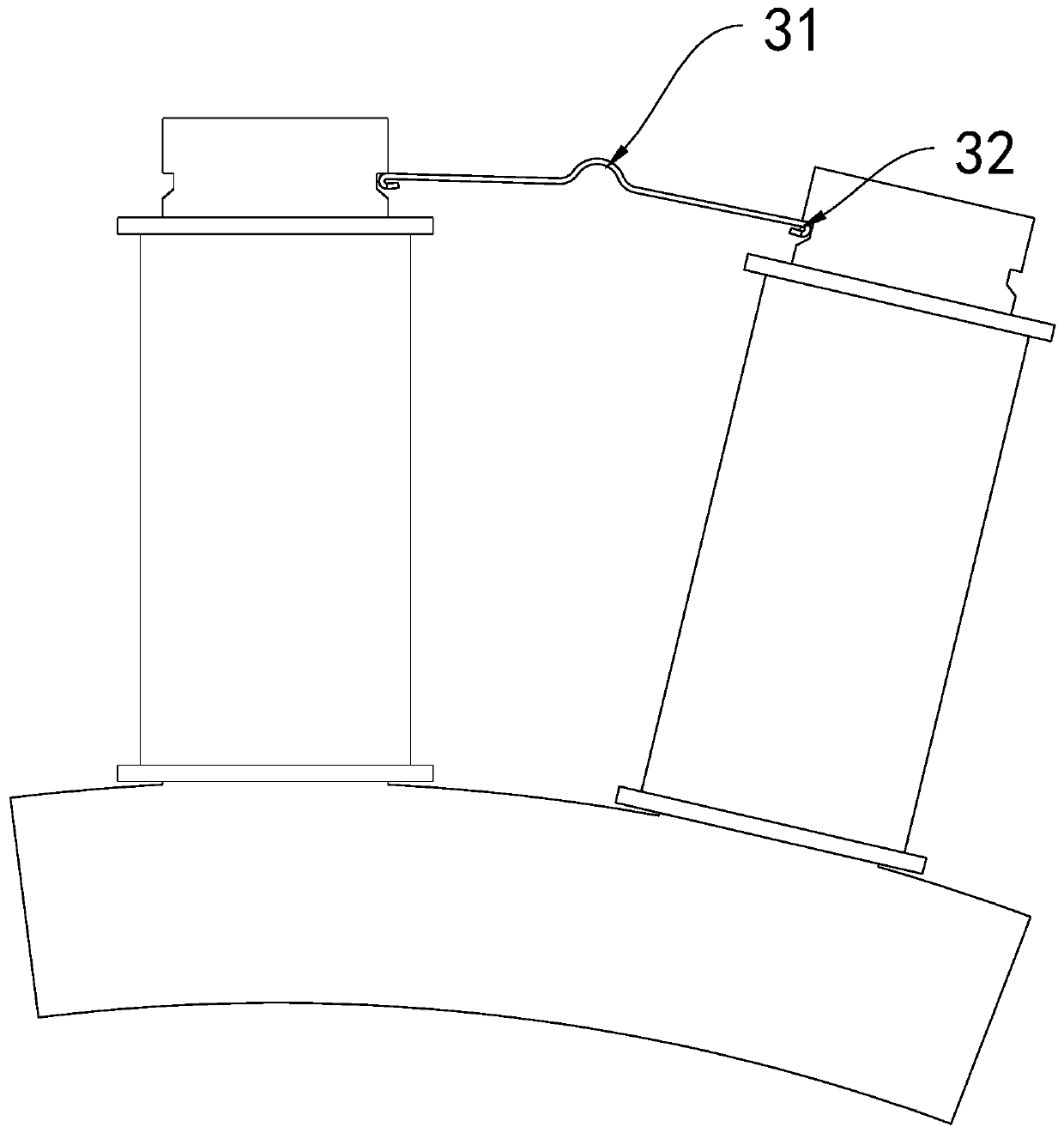

[0020] An elastic portion 31 is disposed in the middle of the insertion piece 30 , and the width of the insertion piece 30 is changed through deformation of the elastic portion 31 . Specifically, the radial section of the elastic portion 31 is arc-shaped. The edge matching the groove 13 on the insertion piece 30 is provided with a curling portion 32, and the two ends of the curling porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com