Rapid tripping device

A tripping device and fast technology, applied in electrical components, electrical switches, protection switch operation/release mechanisms, etc., can solve problems such as impact, impact on assembly efficiency, impact on the tripping function of circuit breakers, etc., to achieve high short-circuit breaking capacity, The effect of high breaking current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

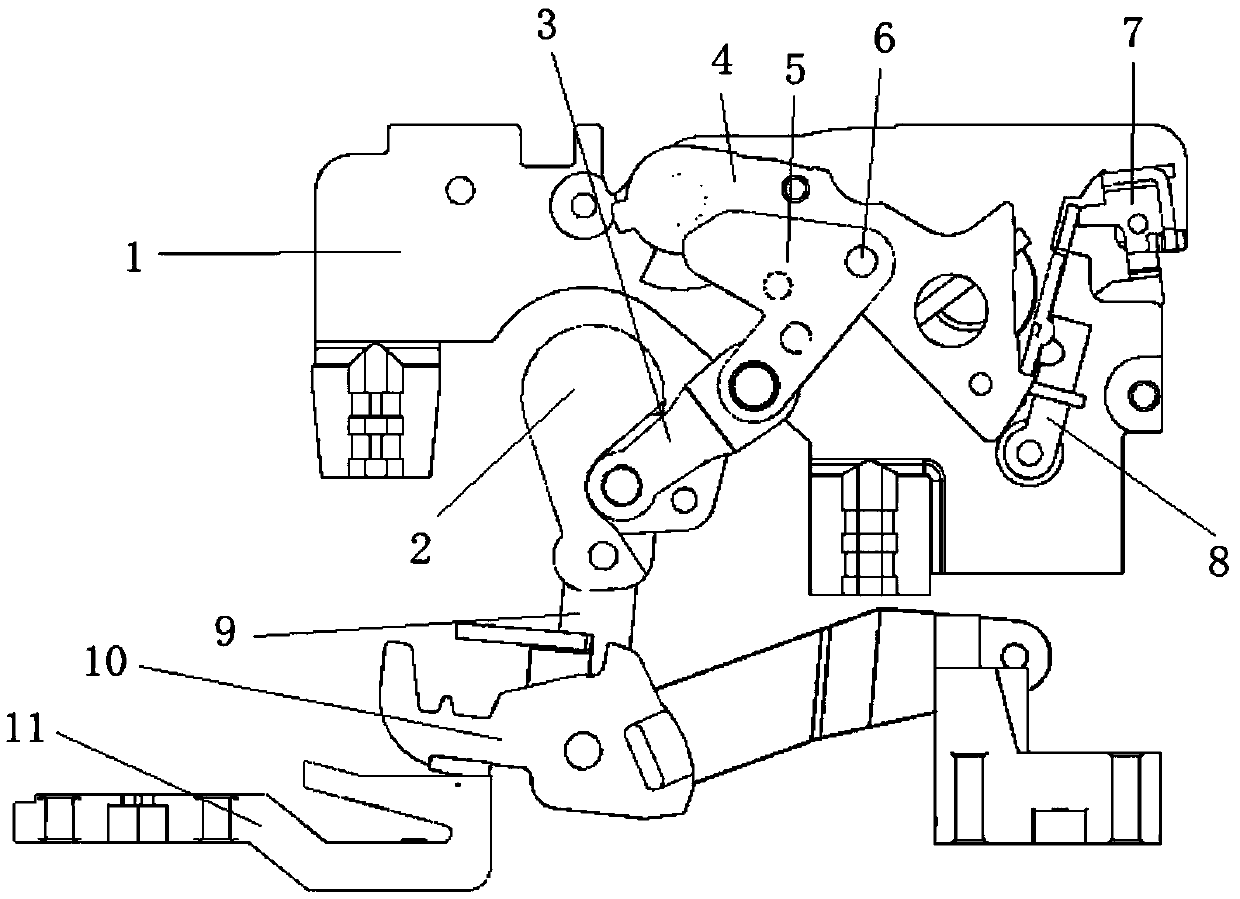

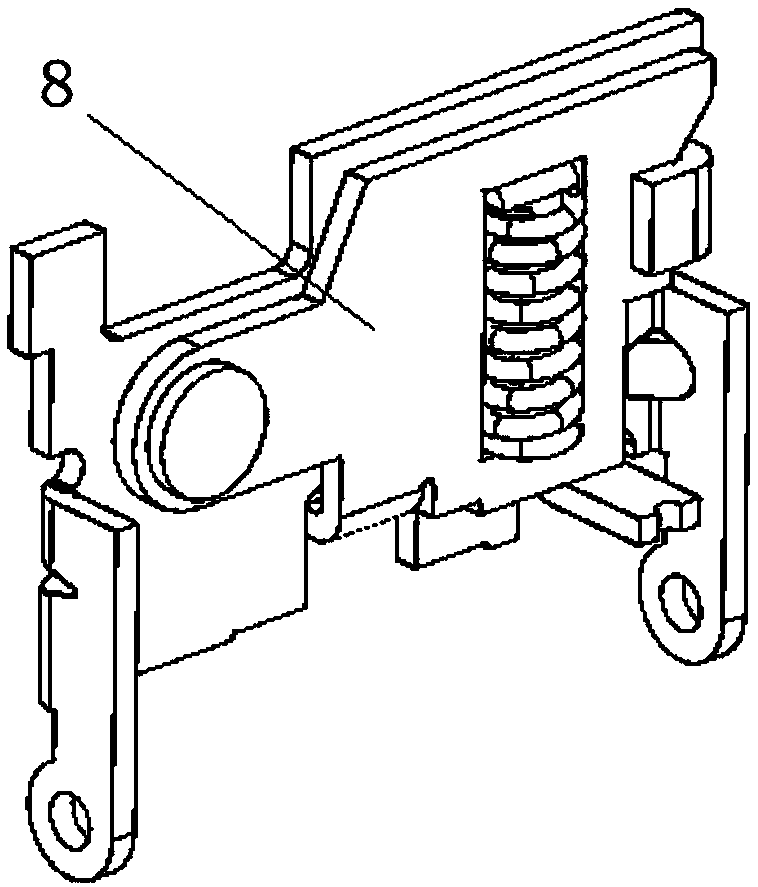

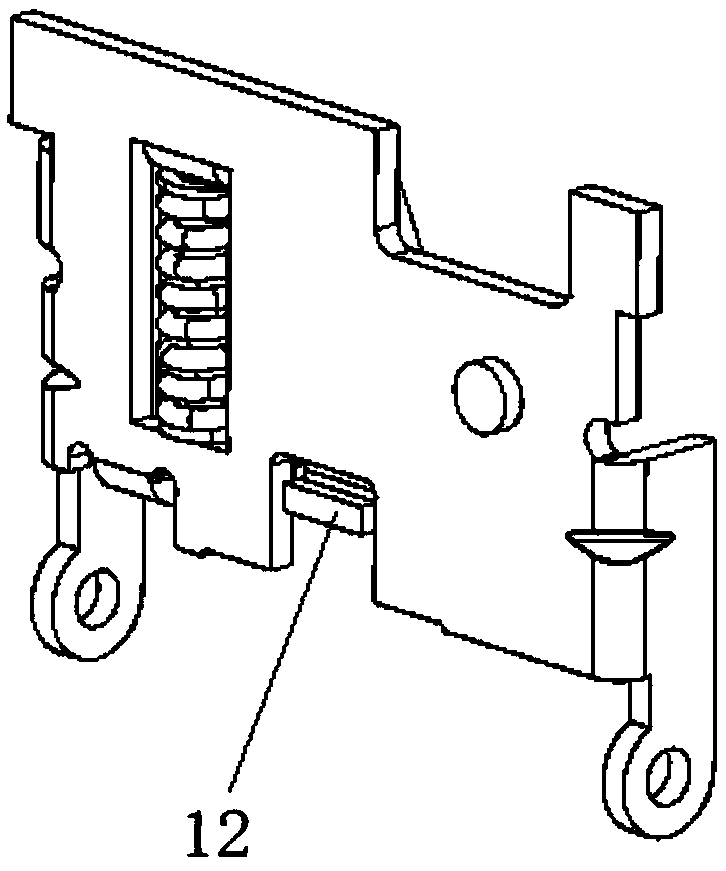

[0035] Such as figure 1 As shown, a quick release device of the present invention includes a mechanism bracket 1, an upper link 5, a lower link 3, a contact link 9, a main shaft 2, a moving contact 10, a static contact 11, and a jumper 4 , the first lock assembly 8, the second lock 7, two upper connecting rods 5 are located on both sides of the jumper 4, and the two upper connecting rods 5 pass through the upper connecting column 6 and the jumper 4 respectively. connected, the lower link is rotatably connected to the upper link at one end and is rotatably connected to the contact link at the other end, the lock is pivotally connected to the mechanism bracket 1, and In the overload state, the moving contact and the static contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com