Electromagnetic relay deicing system

An electromagnetic relay and elimination system technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relay, etc., can solve the problems that metal cannot be contacted, cannot be electrically conducted, cannot supply power or send signals through electromagnetic relay, etc., to achieve elimination Effect of icing and suppressing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

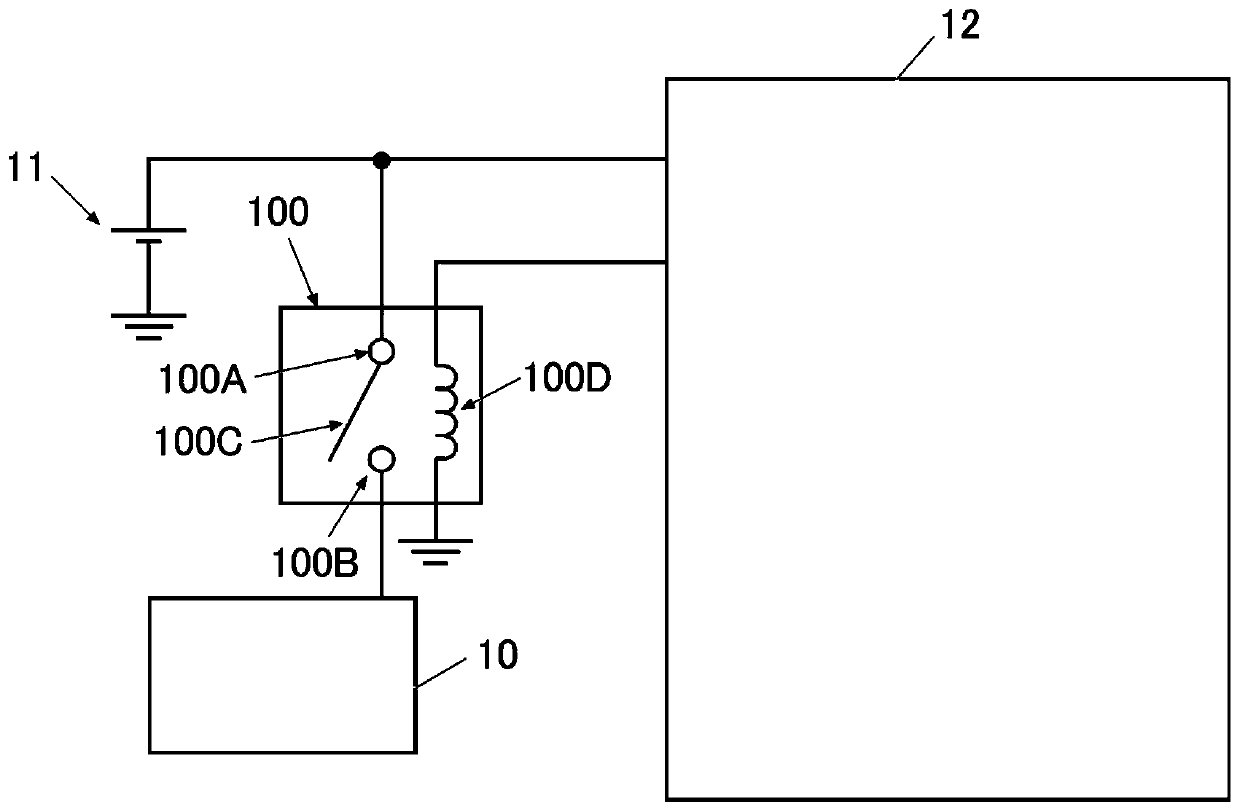

[0068] For example, in electric vehicles, such as figure 1 As shown, there are cases where drive system components 10 such as an inverter are connected to auxiliary battery 11 via electromagnetic relay 100, and power is supplied from auxiliary battery 11 to drive system components 10 via electromagnetic relay 100 when the electric vehicle is started. The drive system component 10 is started.

[0069] It should be noted that after the drive system unit 10 is activated, the power supply mechanism for supplying power to the drive system unit 10 is switched from the auxiliary battery 11 to a main battery not shown or the like.

[0070] Such as figure 1 As shown, in this case, the electromagnetic relay 100 is composed of a common terminal (COM terminal) 100A, a normally open terminal 100B, a movable piece 100C, an exciting coil 100D, and the like.

[0071] Furthermore, the common terminal 100A is connected to the auxiliary battery 11 , and the normally-open terminal 100B is conne...

no. 2 approach

[0117] In addition, conventionally, there are cases where reserve (standby) wiring and the like are provided in the control circuit.

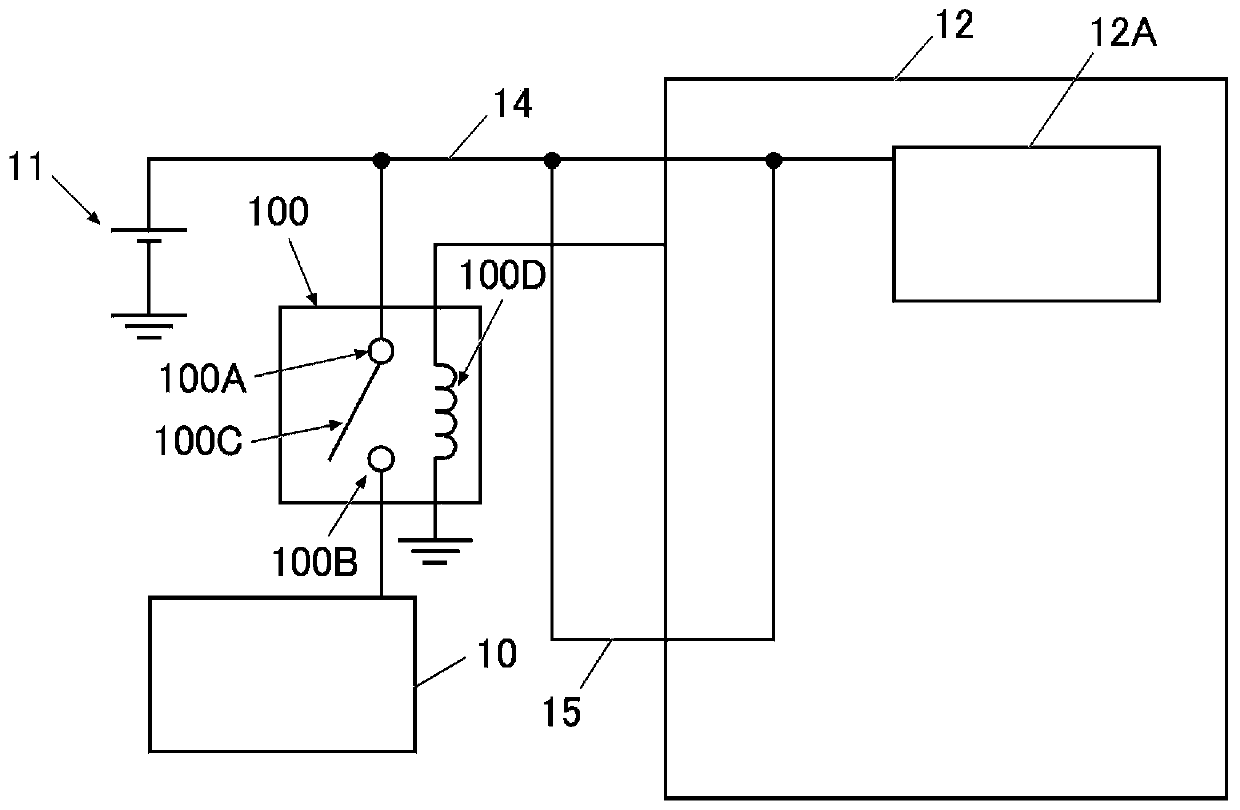

[0118] in e.g. figure 1 In the control system shown, such as image 3 As shown, there is a case where a storage wiring 15 is provided for the main wiring 14 connecting the auxiliary battery 11 and / or the main battery (not shown) and the internal circuit 12A of the control circuit 12 .

[0119] Therefore, the electromagnetic relay deicing system 2 can be configured using the wiring 15 for storage. Hereinafter, it demonstrates concretely.

[0120] In addition, below, the same code|symbol as the case of 1st Embodiment is attached|subjected to the member etc. which are the same as 1st Embodiment, and is shown. In addition, explanations may be omitted for the same members and the like as those of the first embodiment.

[0121] Figure 4 It is a figure which shows the structure of the electromagnetic relay deicing system 2 of this embodiment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com