Design method of PASSIVE product color screen printing based on optimal visual angle

A design method and screen printing technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of unconsidered, waste of mold modification costs, and impact on design timeliness, so as to avoid repeated modifications, maintain a wide viewing angle effect, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

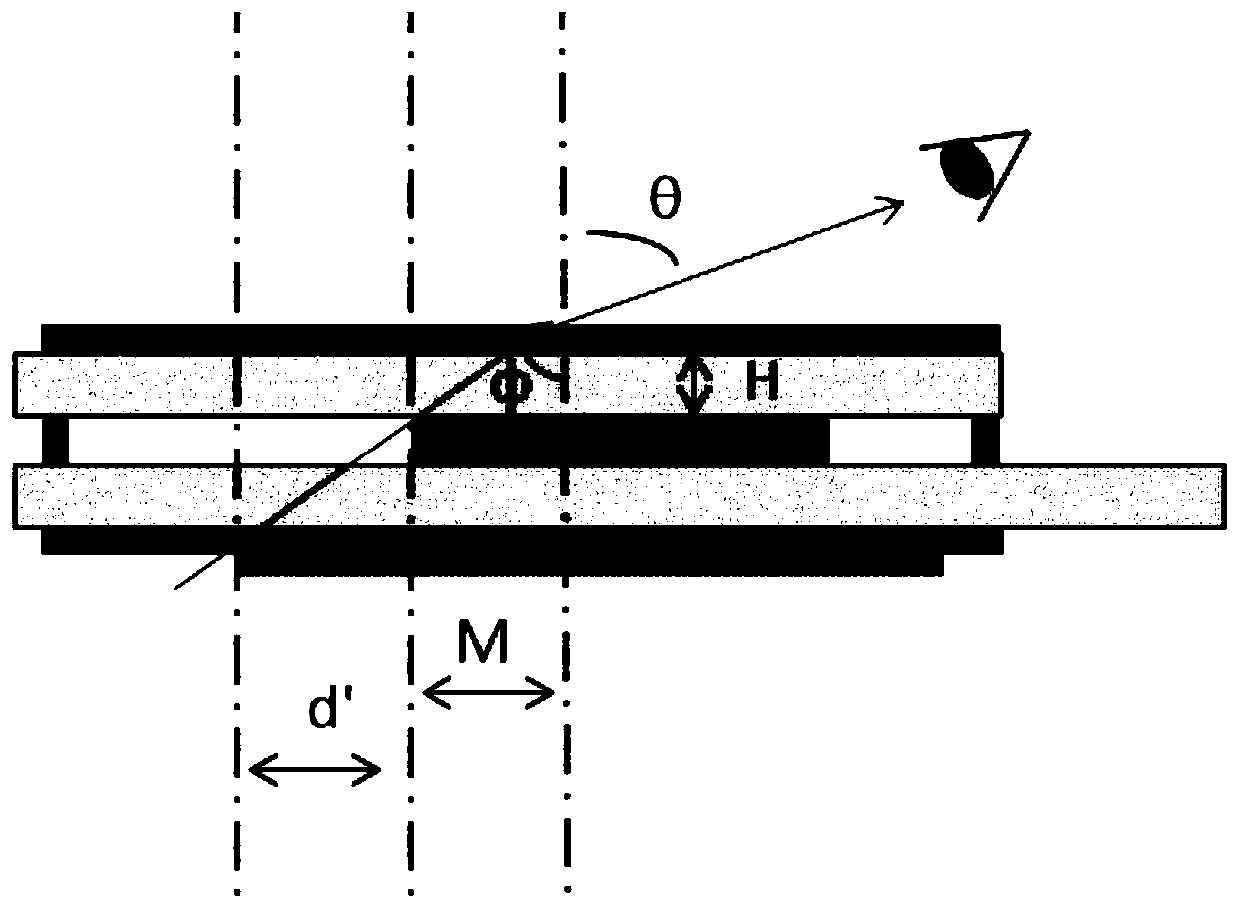

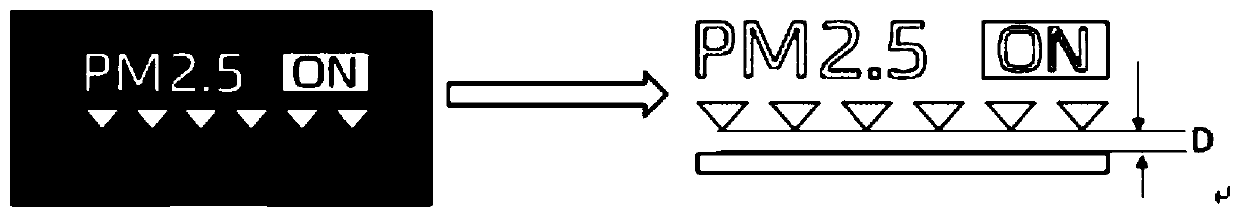

Embodiment 1

[0055] Such as image 3 with Figure 4 In the shown embodiment, the rectangular pattern below PM2.5 is designed as a frame with a red effect, and a monochrome mimeograph design is adopted. The thickness H of the glass is 0.7mm, and the human eyes are vertically upward 0°-45° Observe within the viewing angle range, the bottom rectangular pattern cannot leak white light, and the upper triangular pattern cannot leak red light; according to the above conditions, it is known that the thickness H of the glass is 0.7mm, and Θ is 45°. By querying the H-Θ data From the table, d'=0.34mm is obtained, and the spatial distance between two ICON patterns (the distance between the silkscreen pattern and the non-silkscreen pattern) is obtained through the calculation formula of monochrome silkscreen D=0.6mm+2*d'= 1.28mm, at this time the silk screen size X=B+d'=0.64mm, so you need to leave a space distance of 1.28mm when starting to design the silk screen pattern, and the silk screen size X i...

Embodiment 2

[0057] Such as image 3 with Figure 4In the shown embodiment, the rectangular pattern below PM2.5 is designed as a frame with a red effect, and the multi-color silk screen design is adopted. The glass thickness H is 1.1mm, and the human eyes are vertically upward 0°-45° Observe within the viewing angle range, the bottom rectangular pattern cannot leak white light, and the upper triangular pattern cannot leak red light; according to the above conditions, it is known that the thickness H of the glass is 1.1mm, and Θ is 45°. By querying the H-Θ data From the table, d'=0.54mm is obtained, and the spatial distance between two ICON patterns (the distance between two adjacent silk screen patterns) is obtained through the calculation formula of multi-color silk screen D=1.2mm+2*d'= 2.28mm, at this time the silk screen size X=B+d'=0.84mm, so you need to leave a space distance of 2.28mm when starting to design the silk screen pattern, and the silk screen size X is 0.84mm, once the ICO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com