Fully-automatic static blasting expanding agent automatic filling device

A technology of static blasting and expansion agent, applied in blasting and other directions, can solve the problem of inability to locate the air hole, and achieve the effect of shortening the construction period, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, combined with Figure 1 to Figure 6 And specific embodiment, the present invention is described further:

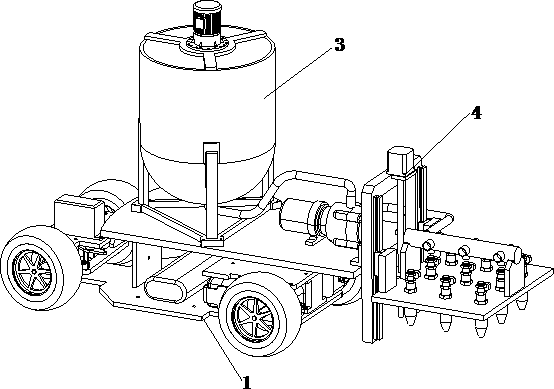

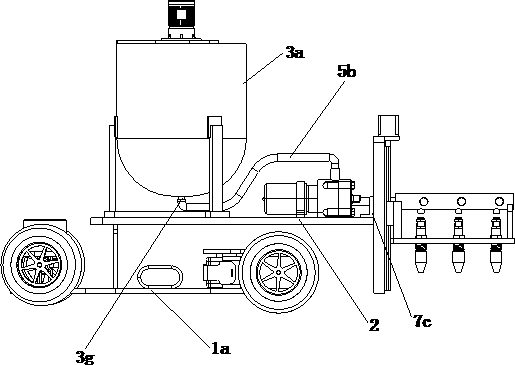

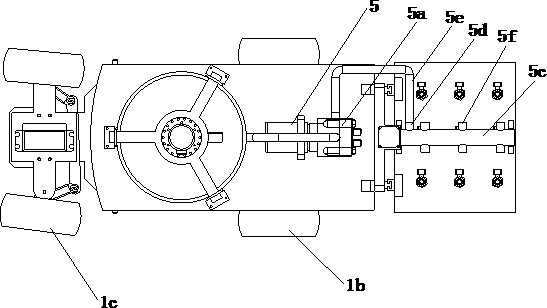

[0026] The present invention provides a fully intelligent static blasting expansion agent automatic perfusion equipment through improvement, such as Figure 1-Figure 6 As shown, it includes a remote control device and a mobile car 1 wirelessly connected to the remote control device. The top of the mobile car 1 is provided with a supporting plate 2 arranged horizontally, and the top of the supporting plate 2 is provided with a stirring mechanism 3. The front end of the supporting plate 2 is provided with an expansion agent injection mechanism 4 , and a material delivery mechanism 5 is provided between the stirring mechanism 3 and the expansion agent injection mechanism 4 .

[0027] According to the principle of the present invention, the worker drives the device to move to the construction site through the remote control device, realizes the automatic stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com