Automatic concrete mixer

A concrete and mixer technology, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of high cost and inconvenient, and achieve the effect of convenient operation, simple control and reasonable structure

Inactive Publication Date: 2010-12-15

舒跃成

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When it is necessary to change the site, it needs to be towed or transported by a vehicle, which is not convenient enough and the cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

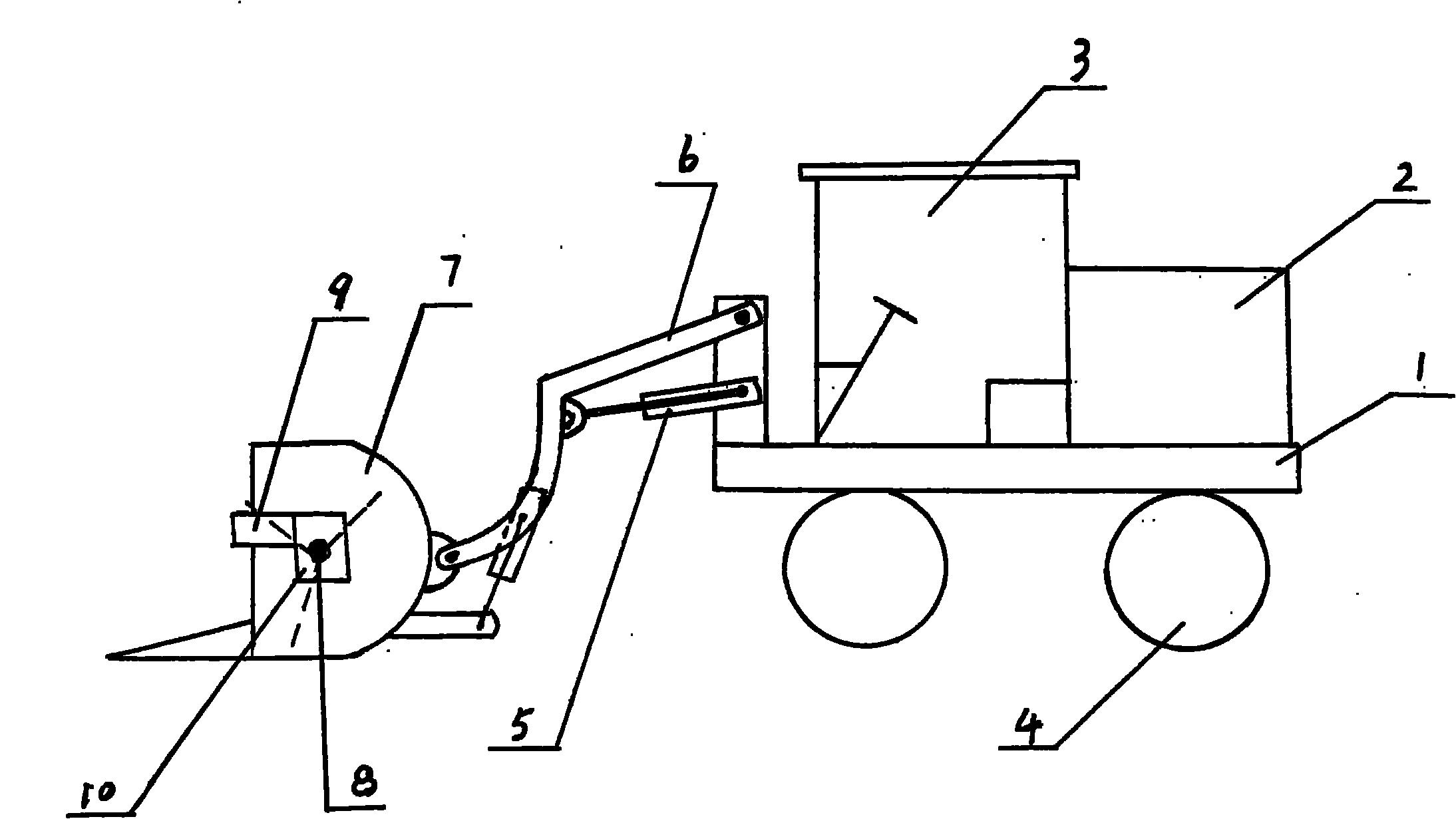

[0008] Such as figure 1 As shown, an automatic concrete mixer includes wheels and a driving mechanism 4, a vehicle frame 1, a driver's cab 3, and an engine room 2. Driven by 5, a hydraulic motor 9 and a stirring gearbox 10 are housed on the shovel 7, and a concrete mixer 8 is arranged in the shovel 8.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to construction machinery, in particular to an automatic concrete mixer which comprises wheels, a driving mechanism, a carriage, a cab and an engine room. The automatic concrete mixer is characterized in that the carriage is connected with a scoop by a connecting rod, the connecting rod is driven by a hydraulic cylinder assembly, the scoop is provided with a hydraulic motor and a mixing gearbox, and a concrete mixer is arranged in the scoop. When in use, the wheel driving mechanism drives the wheels to travel, and sandstone, cement and other materials in the scoop are driven by the hydraulic assembly and introduced into the scoop. Because the concrete mixer is directly arranged in the scoop and is driven by the hydraulic motor, materials can be automatically mixed in the scoop without using additional mixing tanks. The automatic concrete mixer has the advantages of reasonable structure, simple control and convenient operation.

Description

technical field [0001] The invention belongs to construction machinery, in particular to an automatic concrete mixer. Background technique [0002] Existing concrete mixers are generally fixedly installed on the construction site to operate, and need to manually load sand, gravel and cement, pour out the concrete after mixing, and then use manual or other mechanical equipment to transport the mixed concrete. When it is necessary to change the site, it needs to be towed or transported by a vehicle, which is not convenient enough and the cost is high. Contents of the invention [0003] The object of the present invention is to aim at the deficiencies of the prior art, and provide an automatic concrete mixer with reasonable structure, convenient use and stronger practicability. [0004] Technical scheme of the present invention is as follows: [0005] An automatic concrete mixer, including wheels and a driving mechanism, a vehicle frame, a driver's cab, and an engine room. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B28C9/04B28C5/42

Inventor 舒跃成

Owner 舒跃成

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com