Prestressed steel beam and ultrathin sandwich floor adopting prestressed steel beam

A technology of prestressing and section steel, applied in the direction of joists, girders, truss beams, etc., can solve the problems of lower floor height, high requirements for workers' construction level, and complex construction, so as to reduce the thickness of the interlayer, improve the floor height and space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

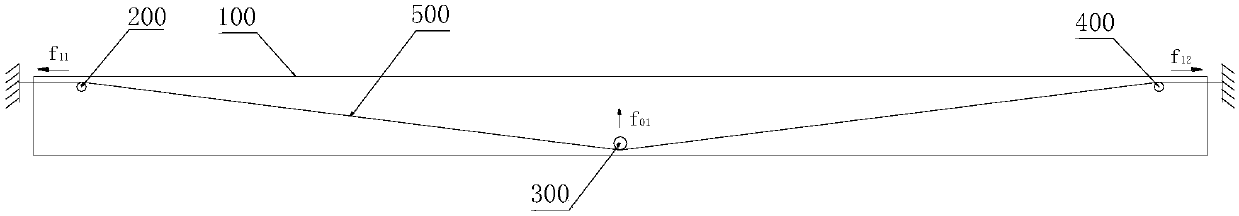

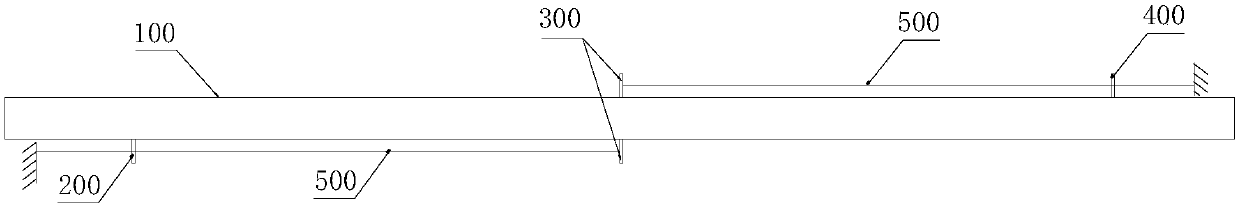

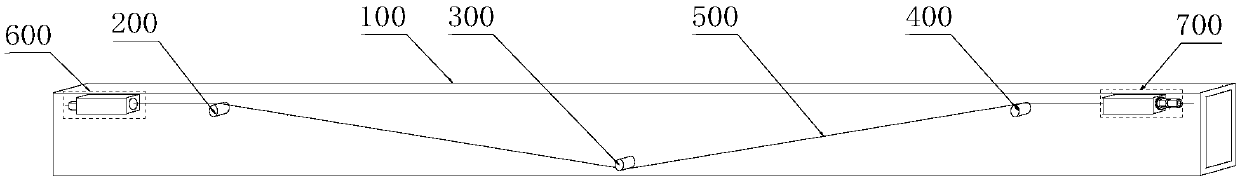

[0112] In this patent document, the following discussed Figure 1-35 The various examples and examples used to describe the principles or methods of the present disclosure are by way of illustration only and should not be construed in any way to limit the scope of the present disclosure. Those skilled in the art should understand that the principles or methods of the present disclosure can be implemented in any suitably arranged steel girders and steel girder sandwich floor structures. Preferred embodiments of the present disclosure will be described below with reference to the accompanying drawings. In the following description, detailed descriptions of well-known functions or configurations will be omitted so as not to obscure the subject matter of the present disclosure with unnecessary detail. Also, the terms used herein will be defined according to the functions of the present invention. Therefore, the terms may be different according to user's or operator's intention o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com