Ultrasonic pile detection testing device enabling transducers to be synchronously moved at equal distance

A synchronous testing and transducer technology, applied in the testing of infrastructure, construction, infrastructure engineering, etc., can solve the problems of reducing detection efficiency, prolonging operation time, inconsistent signal line length, etc., to improve detection efficiency and improve accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

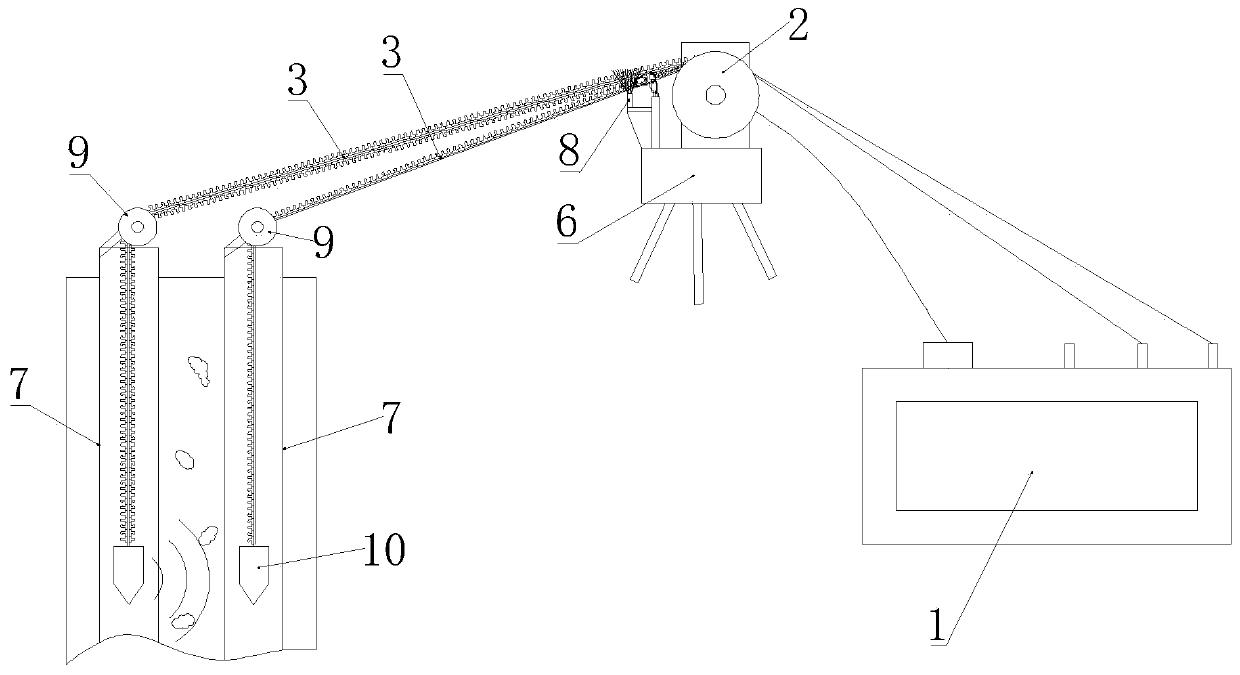

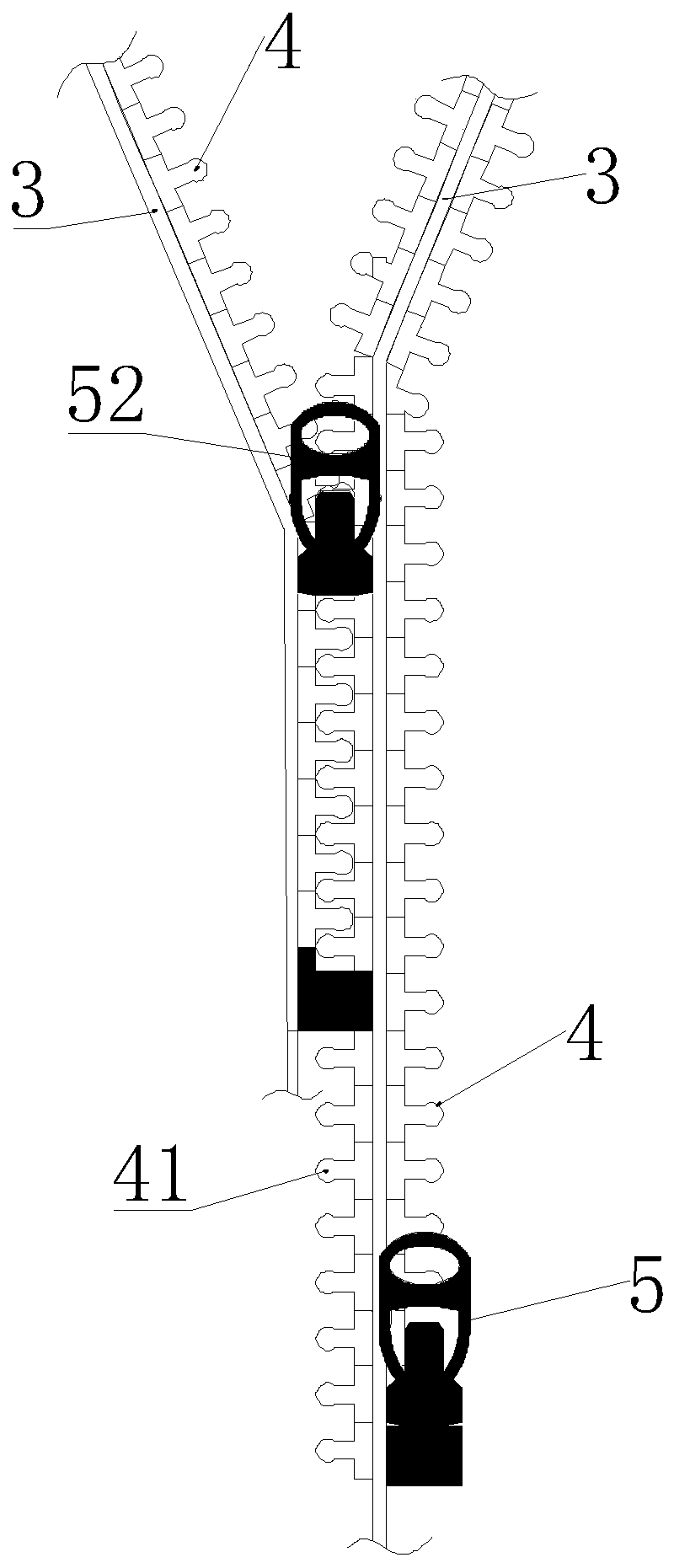

[0024] An equidistant synchronous testing device for ultrasonic pile measuring transducers, comprising an ultrasonic detector 1, a pulley 2 and a signal line 3, the signal line 3 is wound on the pulley 2, and a transducer 10 is installed at its end, The signal wires 3 are a pair, and the two signal wires 3 are fixedly connected through the engaging part 4, the engaging part 4 can be opened and fastened, and the buckle 5 is installed on the engaging part 4, The buckle 5 can control the fastening of the engaging portion 4 .

[0025] Wherein, the engaging part 4 is a zipper, and the two chains of the zipper are respectively fixed on the two signal lines 3, and the buckle 5 is a sliding part 1 on the zipper, and the sliding part 1 is a zipper, The zipper part between the zipper one and the transducer 10 is in an open state. Both the pulley 2 and the buckle 5 are installed on the tripod 6 , and the buckle 5 is located on the side where the end of the signal line 3 protrudes. Afte...

Embodiment 2

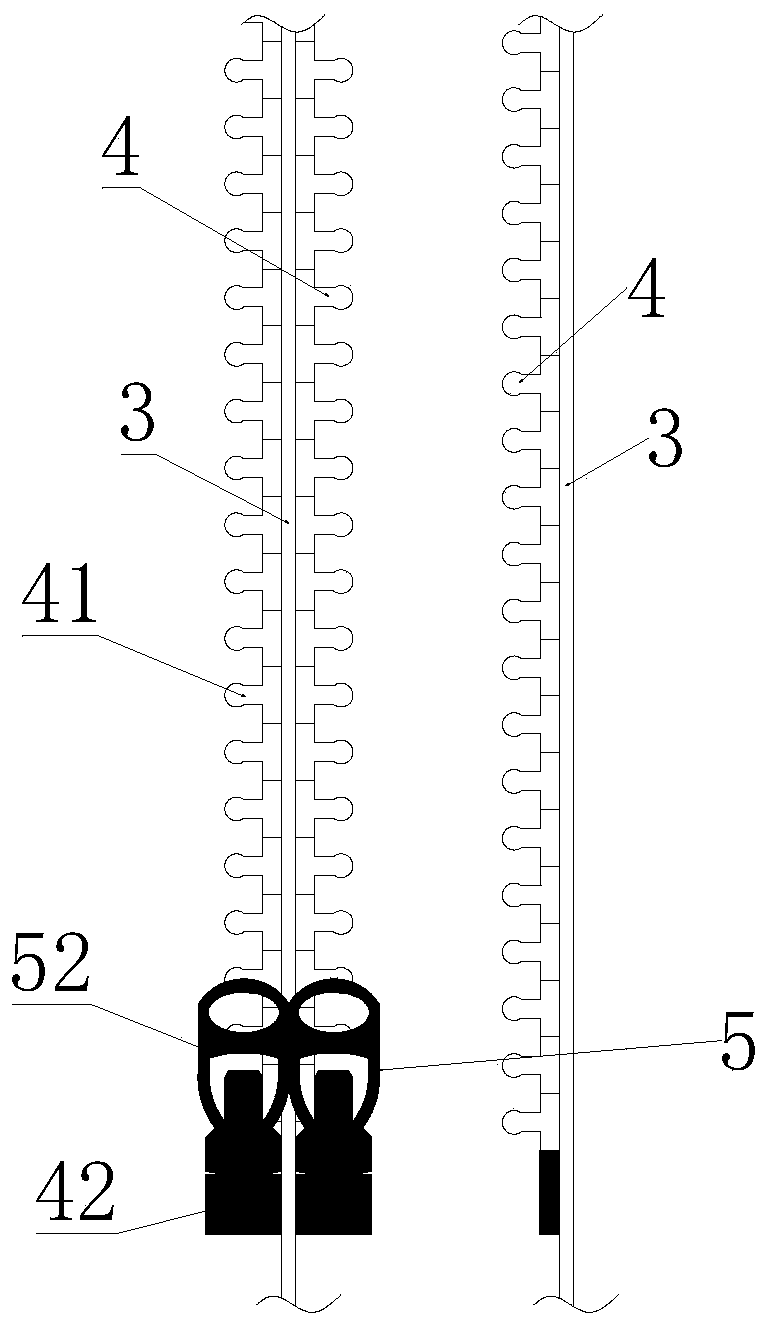

[0029] An equidistant synchronous testing device for ultrasonic pile measuring transducers, comprising an ultrasonic detector 1, a pulley 2 and a signal line 3, the signal line 3 is wound on the pulley 2, and a transducer 10 is installed at its end, The signal wires 3 are a pair, and the two signal wires 3 are fixedly connected through the engaging part 4, the engaging part 4 can be opened and fastened, and the buckle 5 is installed on the engaging part 4, The buckle 5 can control the fastening of the engaging portion 4 .

[0030] Wherein, the engaging portion 4 includes a plurality of evenly distributed paired protrusions 41 and grooves 42 , and the protrusions 41 are inserted into the grooves 42 to fasten and fix the two signal lines 3 to each other. The buckle 5 is a cylindrical structure set on the two signal lines 3 , and the width of the inner cylinder of the buckle 5 is the widest width of the two signal lines 3 after the protrusion 41 and the groove 42 are fastened tog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com