Pile cap of pile hammer and method for adapting to and adjusting diameter of pile cap of pile hammer

An adjustment method and a technology of a piling hammer, which are applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of high cost of piling hammer pile caps, affecting construction efficiency, and cumbersome replacement, so as to achieve safe and fast pile diameter adjustment. The effect of low maintenance cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below.

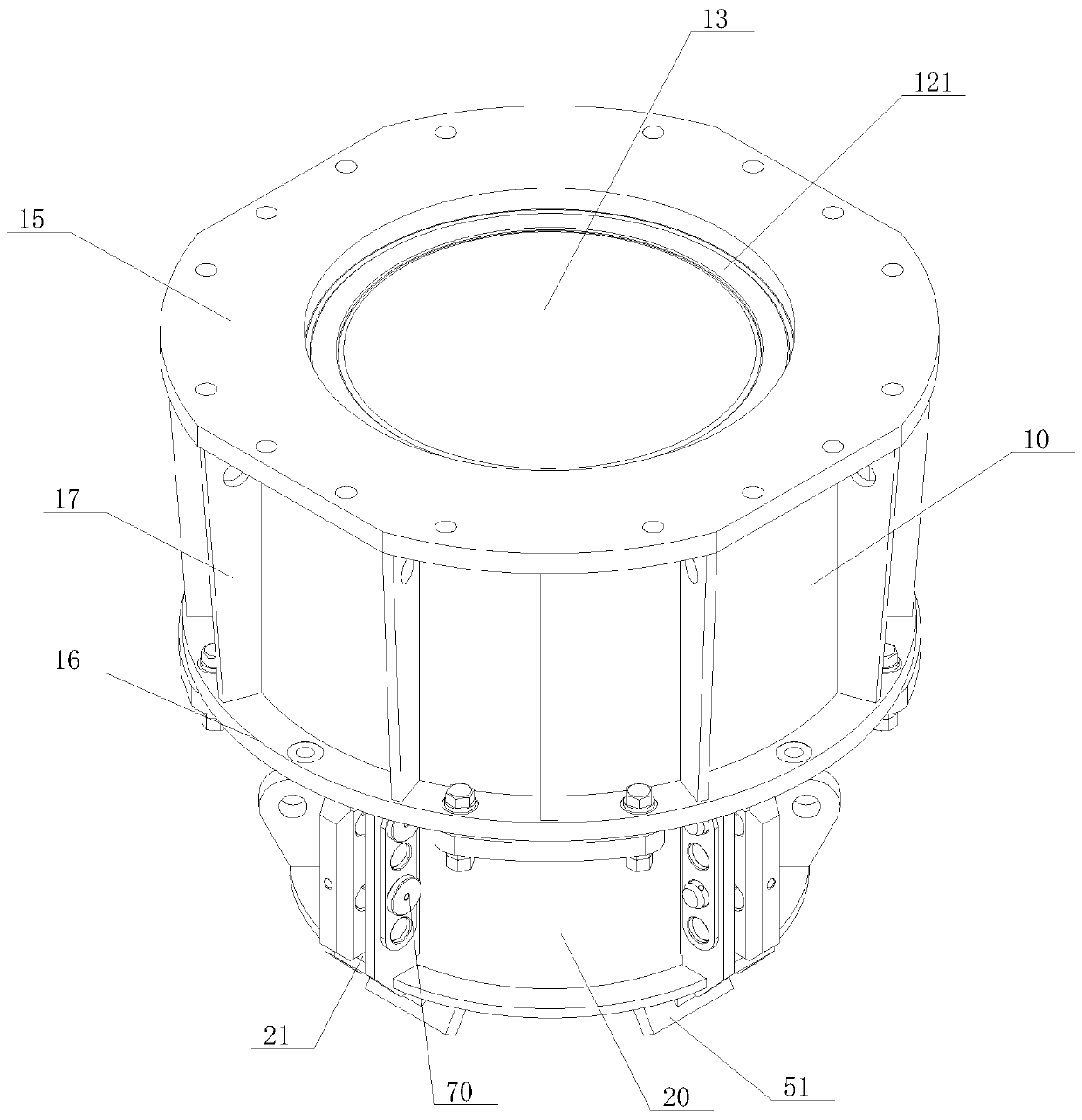

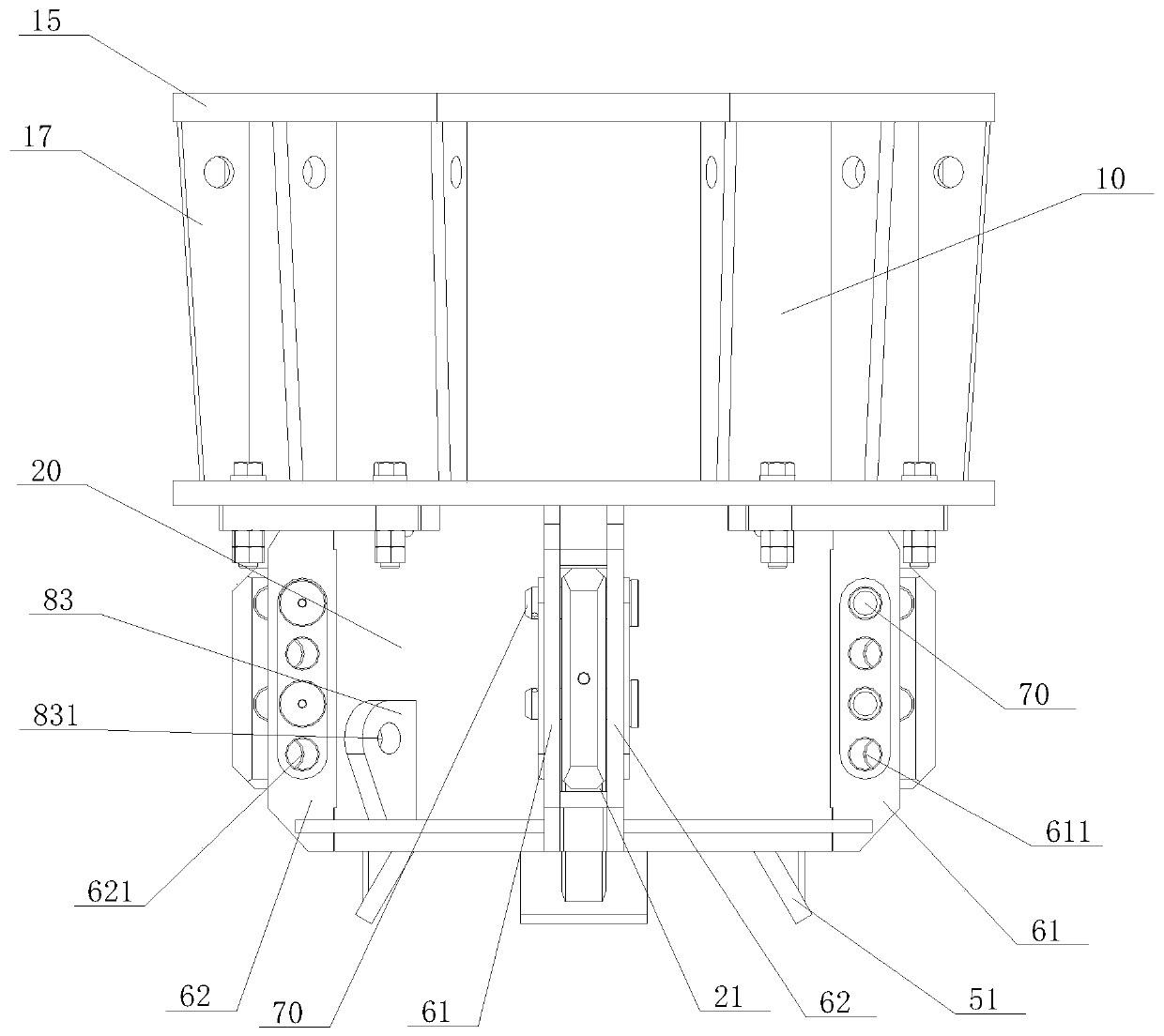

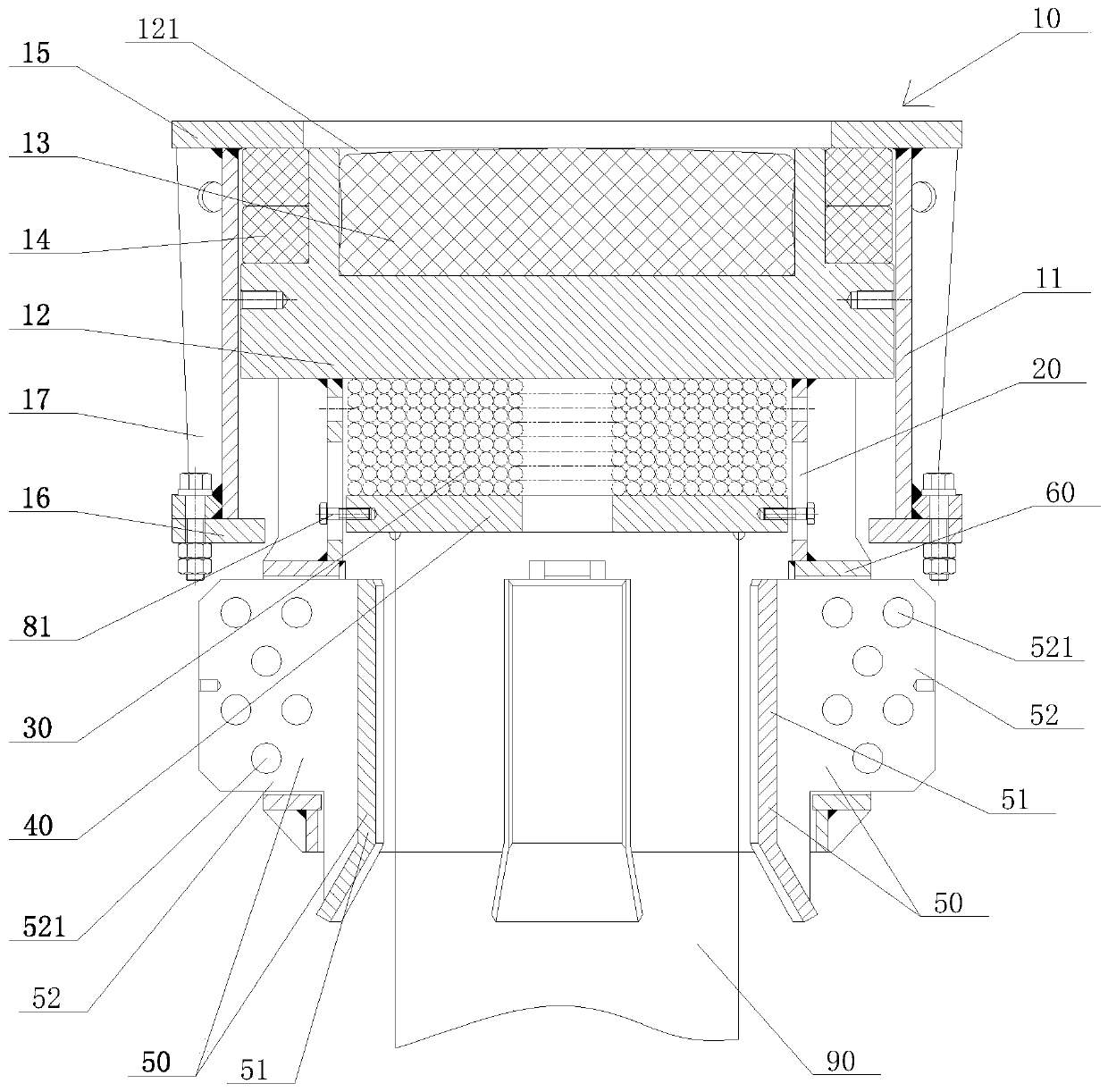

[0047] see Figure 1 to Figure 4 , the diameter adaptation adjustment method of pile cap of pile driving hammer provided by the present invention, comprises the following steps:

[0048] (1), determine pile diameter size, determine the pile head diameter of cement prefabricated pile 90 to be constructed;

[0049] (2), adjust the inner diameter of the lower pile cap, radially move each adjustment block 50 of the piling hammer pile cap, adjust the radial distance between the pile clip 51 of each adjustment block 50 and the central axis of the pile cap, so that each pile The inner cavity diameter of the lower pile cap formed by the clip 51 is compatible with the diameter of the pile head, and the adjustment positioning parts 52 of each adjustment block 50 are fixedly connected with each adjustment support frame 60 with the adjustment pin shaft 70; It includes an upper pile cap 10, a lower cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com