Automatic dust falling system and method for coal unloading point of elevator shaft

A well-lifting, automatic technology, applied in the petroleum industry, gas fuel, fuel and other directions, can solve the problems of difficult to meet occupational health requirements, easy to deteriorate coal quality, and increase system safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

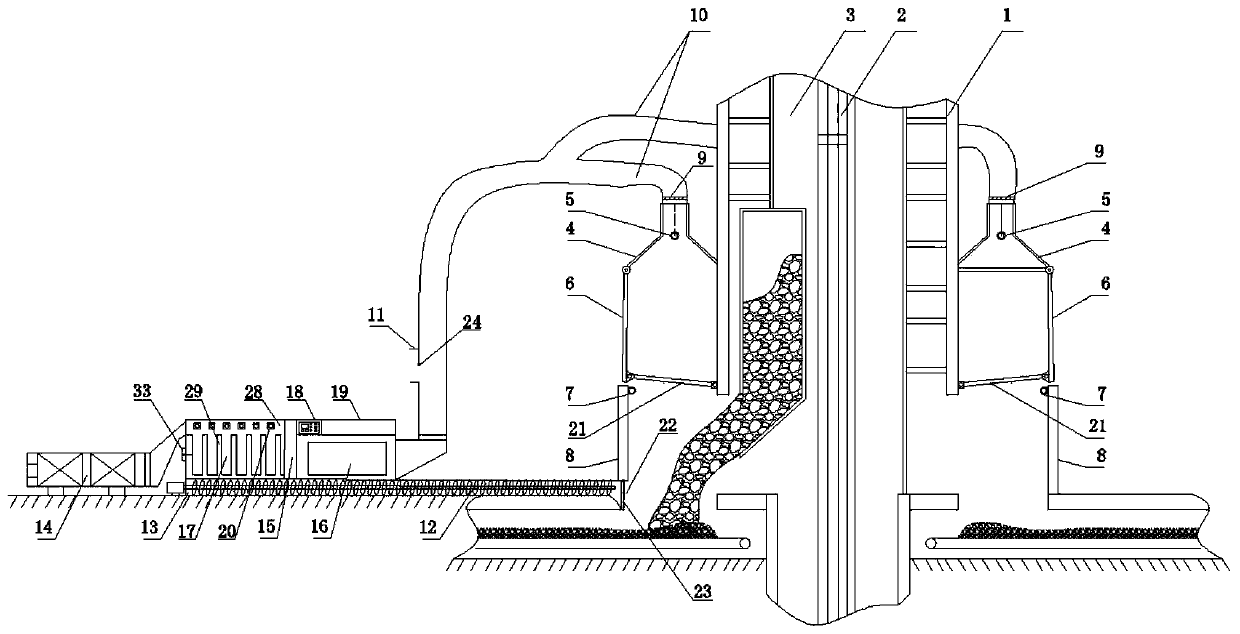

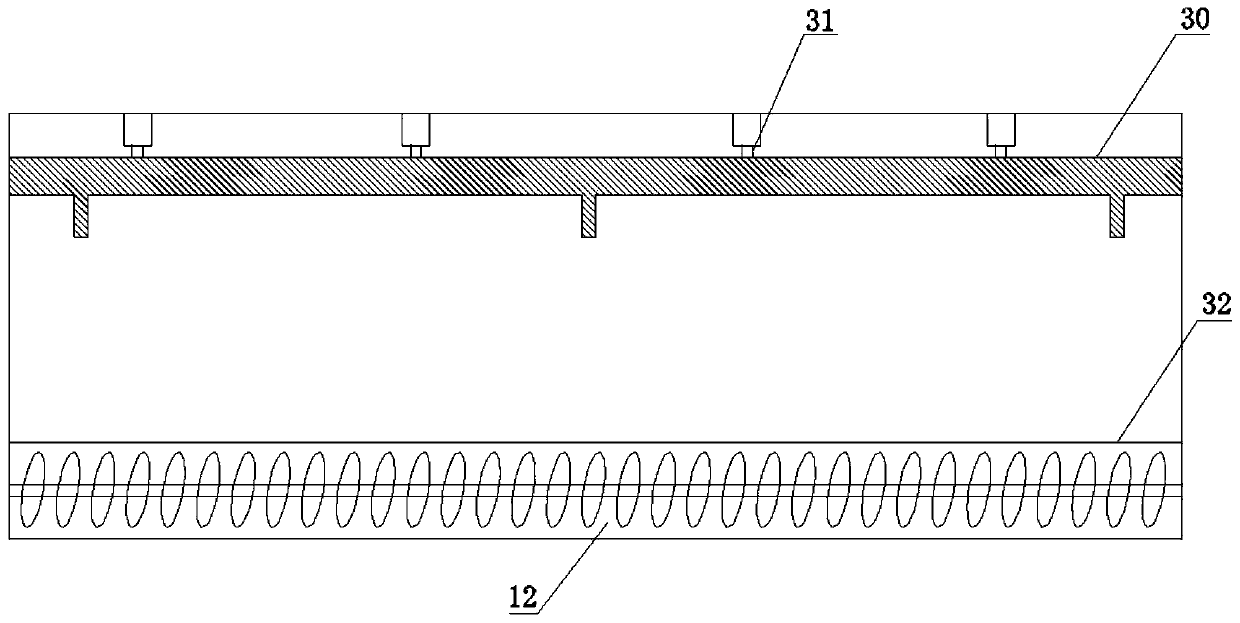

[0039] Such as Figure 1 to Figure 5 As shown, an automatic dust reduction system at the coal unloading point of the lifting shaft includes an axial flow fan 14 arranged outside the lifting shaft 3, a dry dust collector 15, two dust collecting mechanisms, a screw conveyor 12 and a controller 18; The air inlet of the axial flow fan 4 is connected to the air outlet of the dry dust collector 15; two dust collection mechanisms are respectively arranged on the left and right sides of the lifting shaft 3; wherein, the lifting shaft 3 is provided with a lifting rope 2 for lifting;

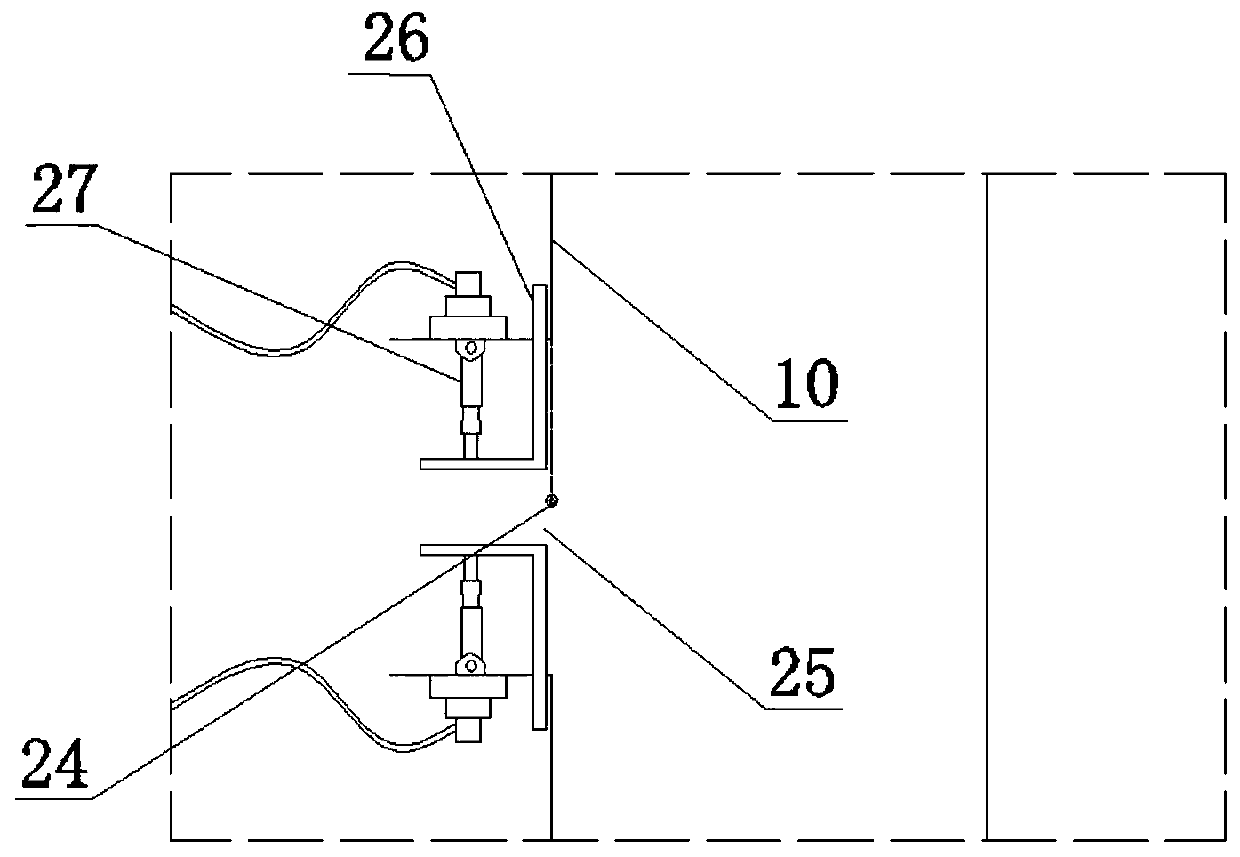

[0040] The dust collection mechanism includes a dust collection cover 4, a transparent dust shield 6, a hydraulic support A21, a control damper 9, a dust concentration sensor 7 and a gas concentration sensor 5; Between the shaft support frame 1 and the side wall 8 of the coal discharge port, and above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com