Cable material containing supramolecular self-assembly flame retardant and preparation method thereof

A supramolecular self-assembly, flame retardant technology, applied in circuits, electrical components, organic insulators, etc., can solve the problems of reduced thermal stability and mechanical properties of cables, mechanical properties, difficult mass production, etc. Stabilizing performance, improving processability, and mitigating thermal decomposition effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

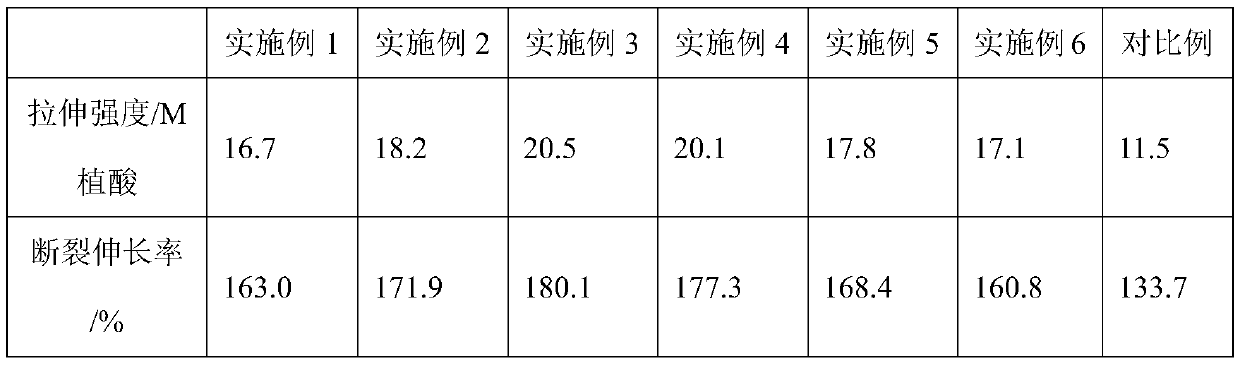

Examples

Embodiment 1

[0026] A cable material containing a supramolecular self-assembled flame retardant in Example 1 is characterized in that, in terms of parts by mass, the flame retardant cable material is made of the following components: 90 parts of polyvinyl chloride; 1 part of acid flame retardant; 67 parts of aluminum hydroxide; 30 parts of plasticizer; 1 part of lubricant; 48 parts of stabilizer; 7 parts of antioxidant.

[0027] Wherein, the melamine phytic acid flame retardant is synthesized from melamine and phytic acid through supramolecular self-assembly technology. First, 4 parts of melamine were dispersed in a three-necked flask with deionized water, put into an oil bath at 80° C., and stirred for 10 minutes. Next, 7 parts of phytic acid aqueous solution was dropped into the three-necked flask through the funnel. The reaction was kept at 80 °C and stirred for 0.5 h. Finally, the obtained product was filtered and washed six times with deionized water at 60° C., and dried at 80° C. f...

Embodiment 2

[0035] A cable material containing a supramolecular self-assembled flame retardant in Example 2 is characterized in that, in terms of parts by mass, the flame retardant cable material is made of the following components: 94 parts of polyvinyl chloride; 2 parts of acid flame retardant; 64 parts of aluminum hydroxide; 34 parts of plasticizer; 1 part of lubricant; 44 parts of stabilizer; 4 parts of antioxidant.

[0036] Wherein, the melamine phytic acid flame retardant is synthesized from melamine and phytic acid through supramolecular self-assembly technology. First, 4 parts of melamine were dispersed in a three-necked flask with deionized water, put into an oil bath at 80° C., and stirred for 10 minutes. Next, 7 parts of phytic acid aqueous solution was dropped into the three-necked flask through the funnel. The reaction was kept at 80 °C and stirred for 0.5 h. Finally, the obtained product was filtered and washed six times with deionized water at 60° C., and dried at 80° C. ...

Embodiment 3

[0044] A cable material containing a supramolecular self-assembled flame retardant in Example 3 is characterized in that, in terms of parts by mass, the flame retardant cable material is made of the following components: 98 parts of polyvinyl chloride; 3 parts of acid flame retardant; 61 parts of aluminum hydroxide; 38 parts of plasticizer; 2 parts of lubricant; 40 parts of stabilizer; 5 parts of antioxidant.

[0045] Wherein, the melamine phytic acid flame retardant is synthesized from melamine and phytic acid through supramolecular self-assembly technology. First, 5 parts of melamine were dispersed in a three-necked flask with deionized water, put into an oil bath at 80° C., and stirred for 10 minutes. Next, 6 parts of phytic acid aqueous solution was dropped into the three-necked flask through the funnel. The reaction was kept at 80 °C and stirred for 0.5 h. Finally, the obtained product was filtered and washed six times with deionized water at 60° C., and dried at 80° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com