Organic fertilizer raw material proteolysis post-treatment method

A technology of proteolysis and organic fertilizer, applied in the direction of organic fertilizer, liquid fertilizer, separation method, etc., can solve the problems of inconvenient operation, unfavorable waste filtration treatment, slow filtration speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The post-processing method of organic fertilizer raw material proteolysis comprises the following steps:

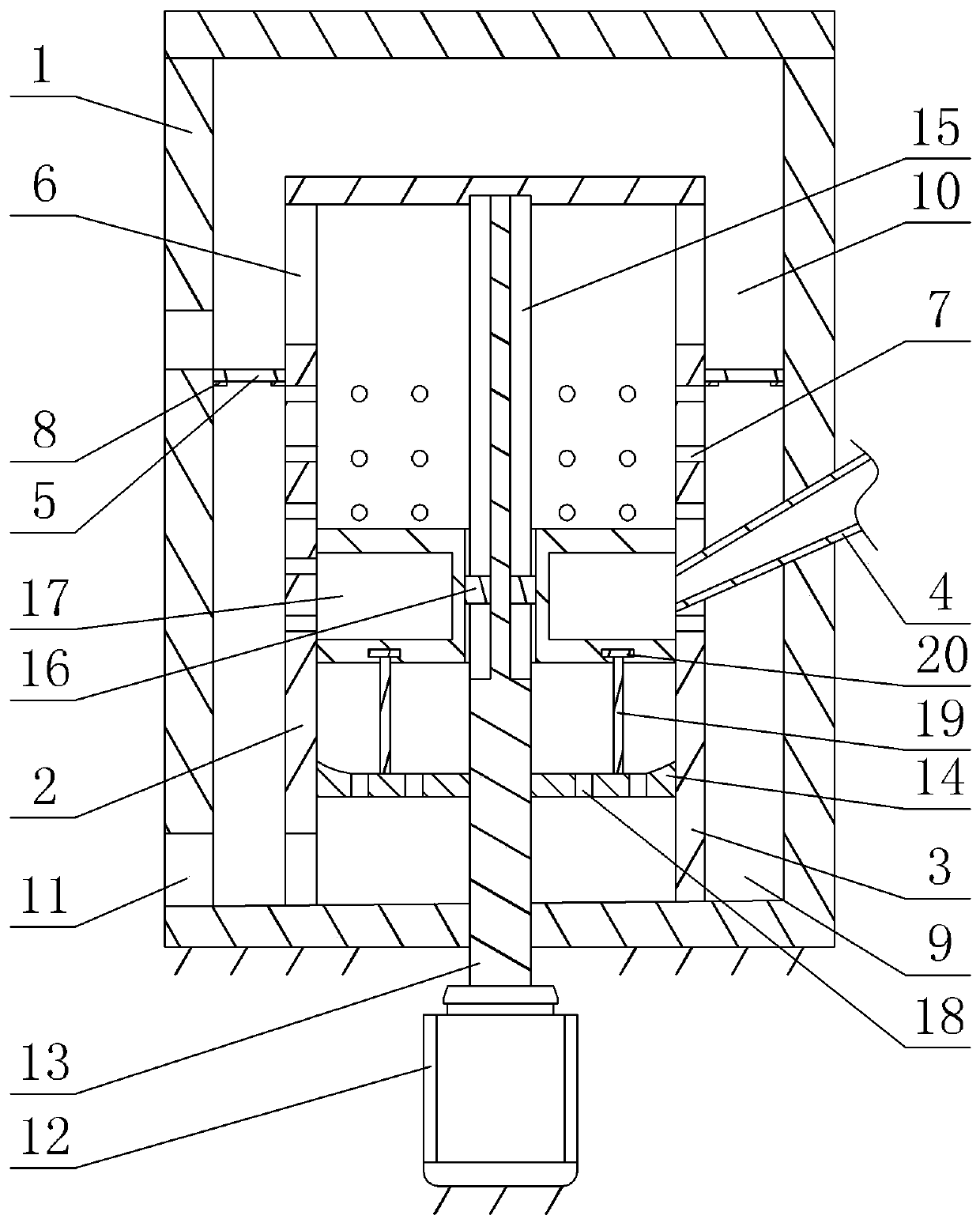

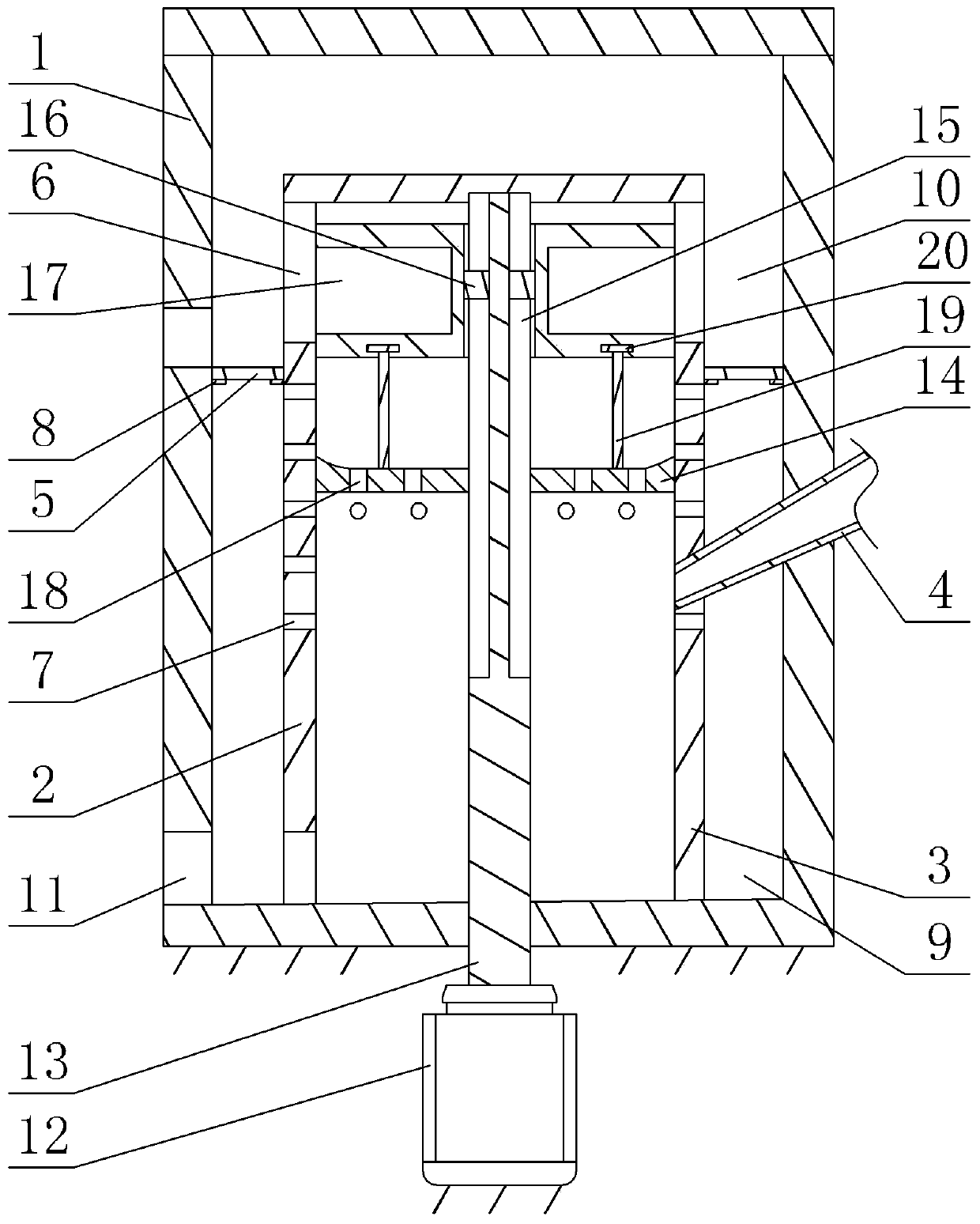

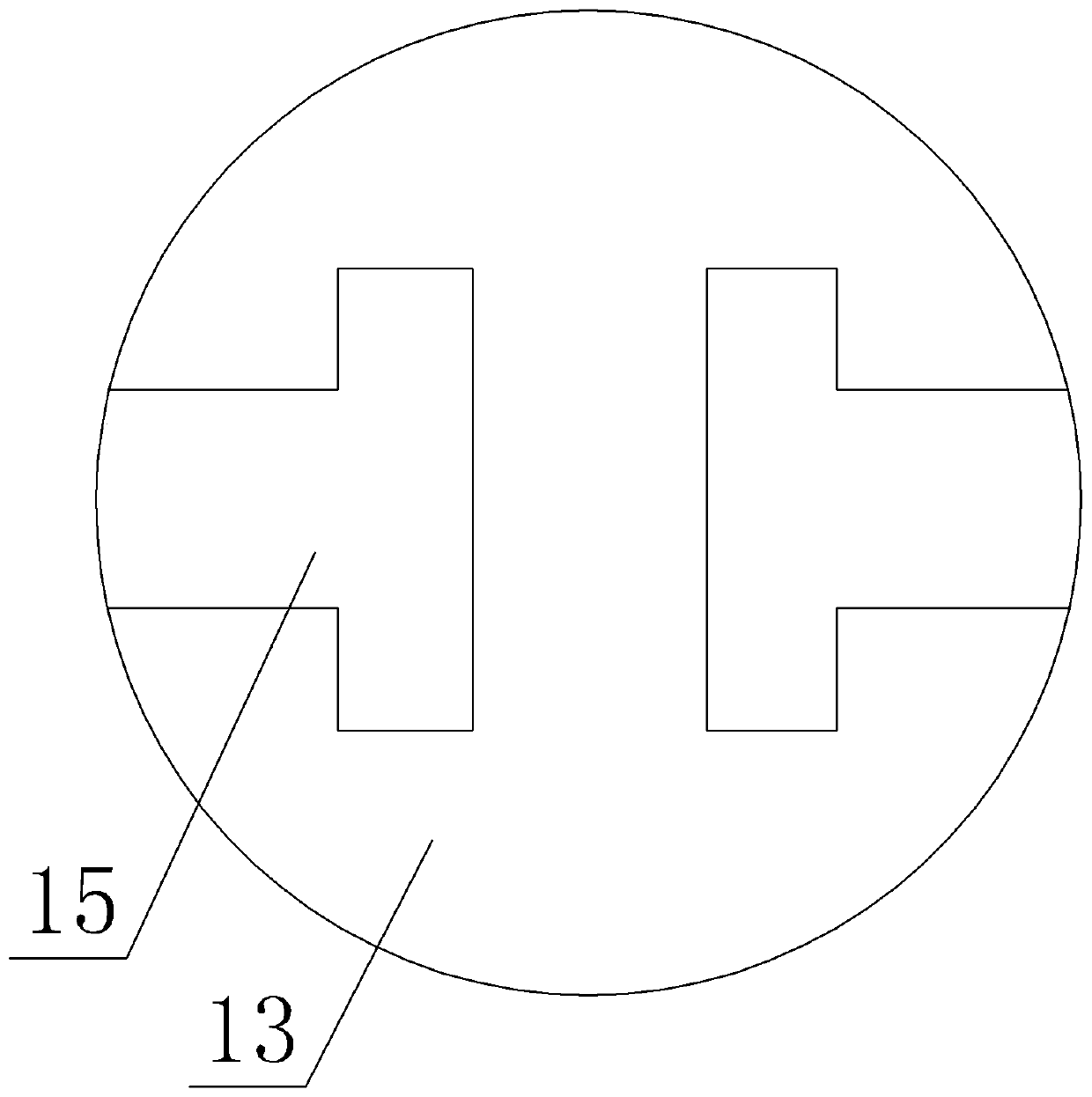

[0027] Step 1: Mix the minced scraps with water, add yeast or Bacillus licheniformis to enzymatically hydrolyze for 3 hours; then prepare a kind such as figure 1 Shown filter device, this filter device comprises frame, outer barrel 1, inner barrel 2, holding material block 3, feeding pipe 4, dividing plate 5 and filter mechanism, outer barrel 1 is fixed on the frame by bolts, inner barrel 2 is installed in the outer barrel 1, the lower end of the inner barrel 2 is welded to the bottom of the outer barrel 1, and the upper ends of the outer barrel 1 and the inner barrel 2 are screwed with a cover.

[0028] The side wall of the inner barrel 2 is provided with a discharge port 6 and some filter holes 7, the aperture of the filter hole 7 is 0.45 μm, and the discharge port 6 is located at the upper end of the inner barrel 2; the inner wall of the outer barrel 1 and the o...

Embodiment 2

[0038] Embodiment 2 is different from Embodiment 1 in that, with figure 1 For reference, in this embodiment, the blockage removal block 14 in the filter device is not threadedly connected with the screw rod 13, but a gap is formed between the blockage removal block 14 and the screw rod 13, and an air cylinder is installed at the bottom of the outer barrel 1 to make the air cylinder output The upper end of the axle is welded with the lower surface of the block removal block 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com